WoodHammerMill machine

Product Details:

- Capacity 20-2200 Kg/hr

- Automatic Yes

- Voltage 230/440 Volt (v)

- Feature High Performance ECO Friendly Low Noise Lower Energy Consumption High Efficiency

- Click to View more

WoodHammerMill machine Price And Quantity

- 18000 INR/Unit

- 1 Unit

WoodHammerMill machine Product Specifications

- Yes

- 20-2200 Kg/hr

- High Performance ECO Friendly Low Noise Lower Energy Consumption High Efficiency

- 230/440 Volt (v)

WoodHammerMill machine Trade Information

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque Western Union

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- ISO

Product Description

-

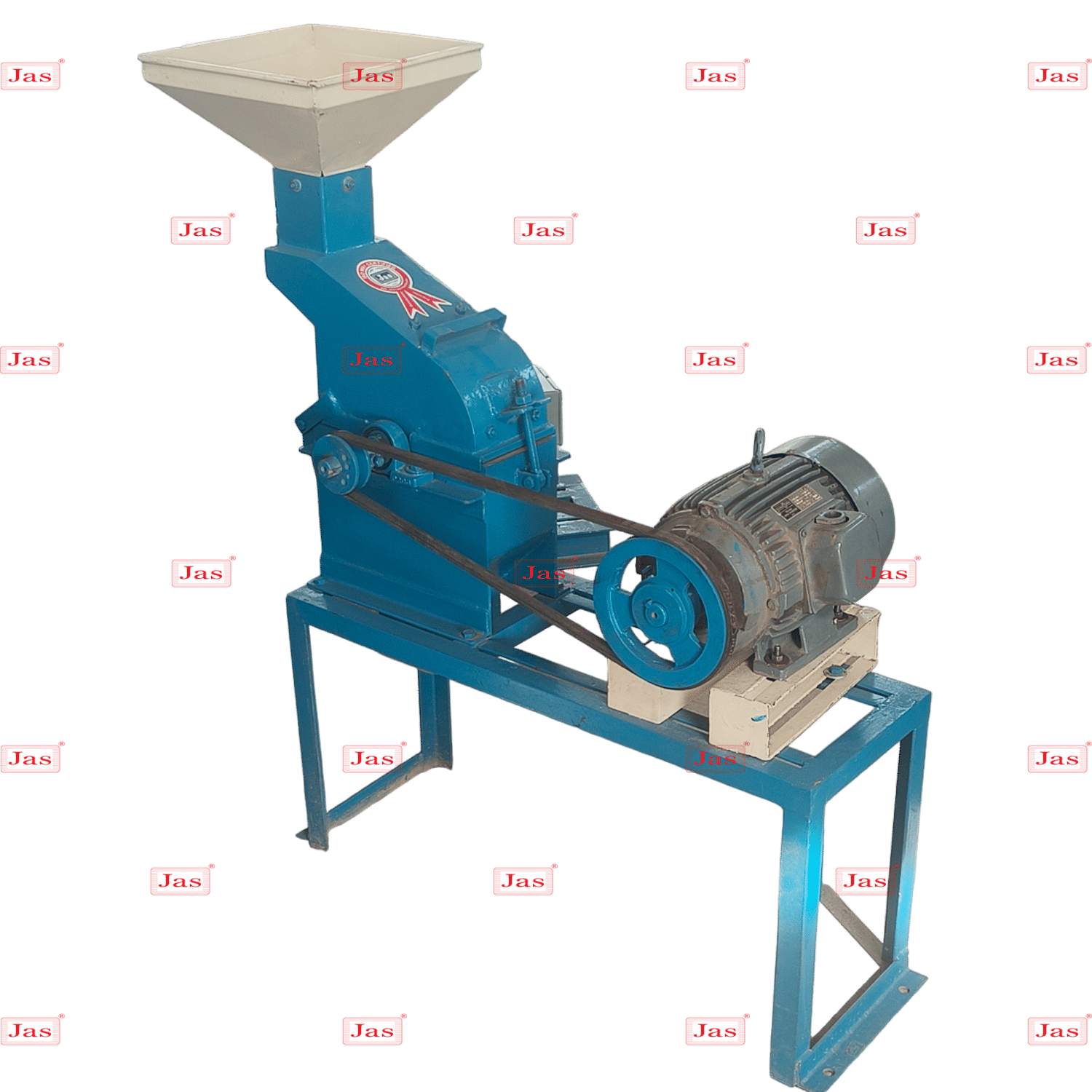

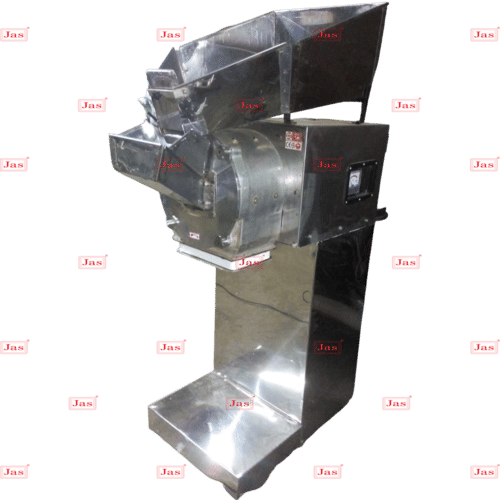

Function: The hammer mill shreds wood by repeatedly striking it with hammers. This process reduces the size of the wood particles, making them suitable for use in various applications like animal feed, biomass fuel, and wood pellets.

-

Components: Major components include the hammers, screen (which controls the size of the output particles), and the rotor (which drives the hammers). The size of the output can be adjusted by changing the screen size or hammer configuration.

-

Types: There are several types of hammer mills, including gravity-fed and pneumatic (air-powered) models. Gravity-fed models allow the wood to fall into the mill by gravity, while pneumatic models use air pressure to move the material.

-

Applications: Wood hammer mills are used in agriculture for processing animal feed, in the timber industry for creating wood chips and sawdust, and in renewable energy sectors for producing biomass fuel.

-

Maintenance: Regular maintenance is necessary to keep the hammer mill running efficiently. This includes checking and replacing worn-out hammers, screens, and other components, as well as ensuring proper lubrication.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+