Hammer Mill Pulveriser

18000 INR/Unit

Product Details:

- Capacity 20-2200 Kg/hr

- Automatic Yes

- Voltage 230/440 Volt (v)

- Feature High Performance ECO Friendly Low Noise Lower Energy Consumption High Efficiency

- Click to View more

X

Hammer Mill Pulveriser Price And Quantity

- 18000 INR/Unit

- 1 Unit

Hammer Mill Pulveriser Product Specifications

- High Performance ECO Friendly Low Noise Lower Energy Consumption High Efficiency

- 230/440 Volt (v)

- Yes

- 20-2200 Kg/hr

Hammer Mill Pulveriser Trade Information

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque Western Union

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- ISO

Product Description

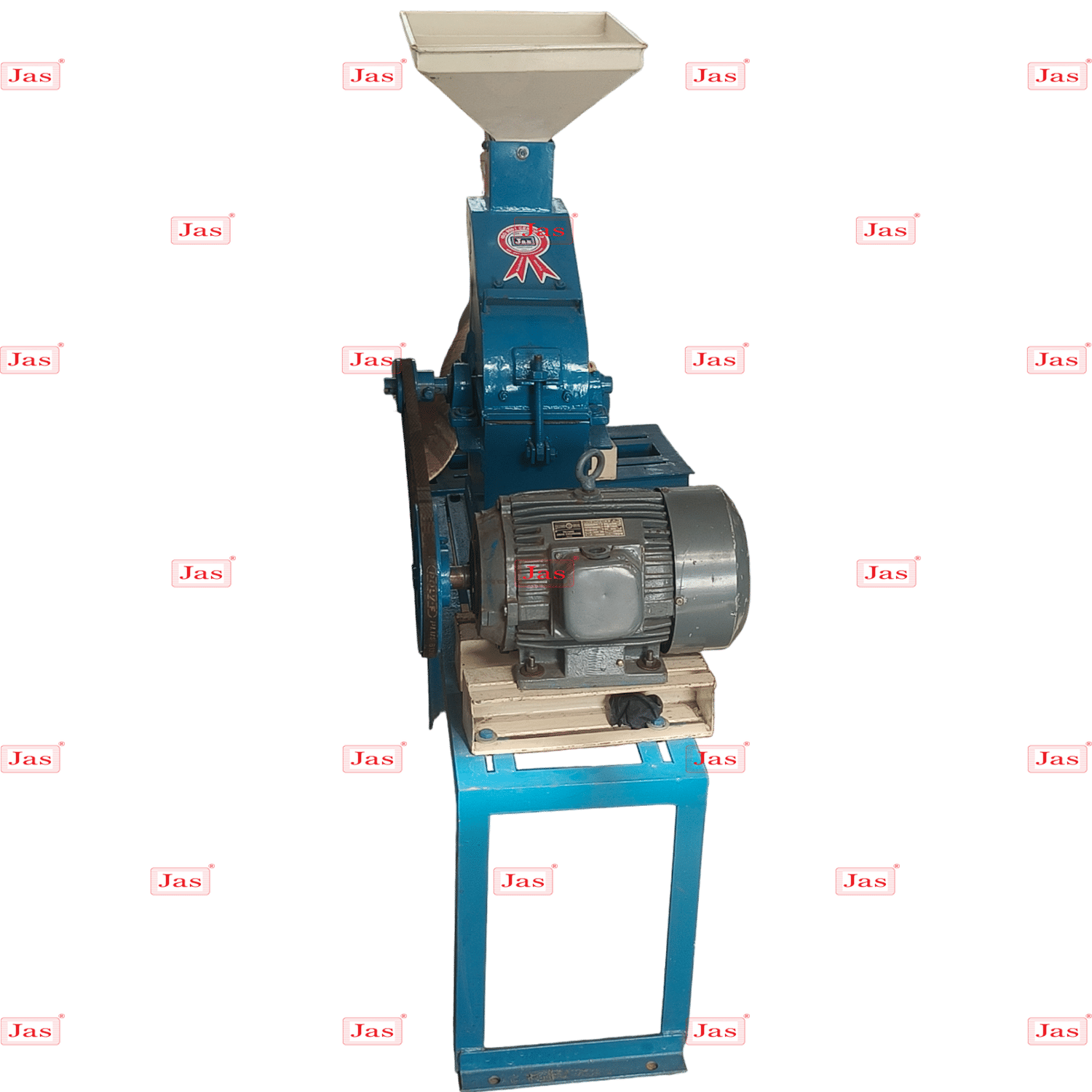

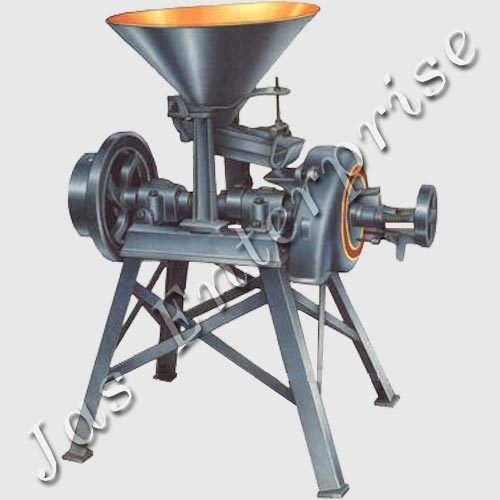

Components:

- Hammer Assembly: This includes a series of heavy hammers or bars that strike the material.

- Rotor: The central shaft to which the hammers are attached, rotating at high speeds.

- Grinding Chamber: The enclosure where the material is fed and ground.

- Screen: Located at the bottom of the chamber, it controls the size of the final product by allowing only particles of a certain size to pass through.

- Inlet and Outlet Ports: For feeding material into the mill and discharging the processed material.

How It Works:

- Feeding: Raw material is fed into the grinding chamber through an inlet.

- Impact and Shearing: As the rotor spins, the hammers strike the material with high force, causing it to break into smaller pieces.

- Screening: The smaller particles that pass through the screen exit the chamber, while larger pieces are repeatedly struck until they are sufficiently small.

- Discharge: The finely ground material is then discharged through an outlet port.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email