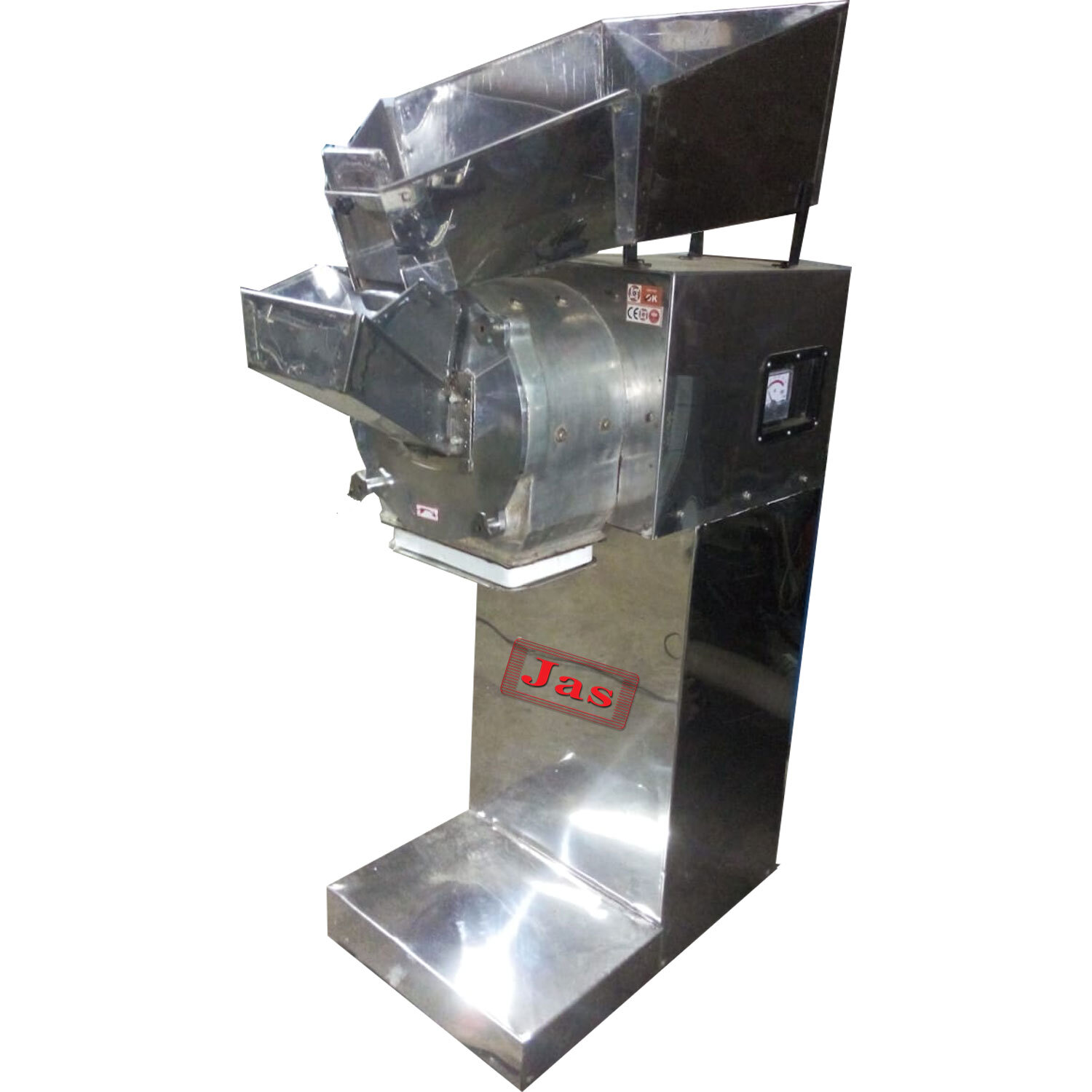

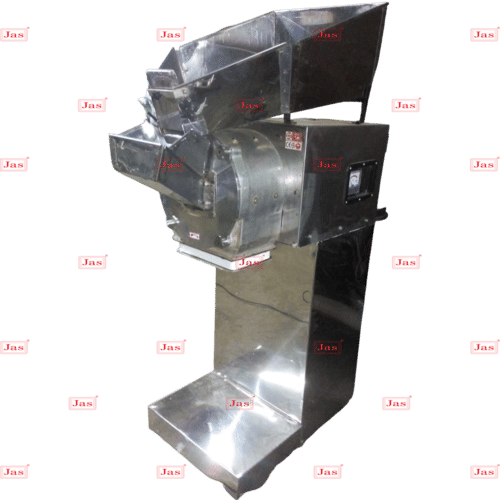

Spice Mill

Product Details:

- Material Stainless Steel

- Capacity 30-35 Kg/hr

- Weight (kg) 60 Kilograms (kg)

- Computerized No

- Automatic Yes

- WorkingSpeed 2800 RPM

- Power 3728 Watt (w)

- Click to View more

Spice Mill Price And Quantity

- 1 Unit

- 15000 INR/Unit

Spice Mill Product Specifications

- 60 Kilograms (kg)

- 2800 RPM

- 3728 Watt (w)

- 110 to 415 Volt (v)

- Stainless Steel

- 30-35 Kg/hr

- Yes

- No

- 36 X 50 X 93 Centimeter (cm)

Spice Mill Trade Information

- 1000 Unit Per Month

- Week

- Yes

- Free samples are available

Product Description

Inspired by the positive response from our clients, we have been committed to manufacture and export sturdily built Spice Mill. This mill is ideal for grinding various spices. Our offered mill is engineered using high grade stainless steel that is procured from accredited vendors of the market. Our offered mill is designed in various sizes, grades and models keeping in mind variegated needs of clients. We deliver this Spice Mill with the help of our trusted logistics personnel within the time specified.

Various characteristics:

- Robust construction

- Seamless finish

- Longer service life

- Less maintenance

Other details:

Jas enterprises offers spice mills, which grinds red chilies, black pepper, red pepper, white pepper, cinnamon, cardamom, coriander,oregano, basil, thyme, dill seed, shell corn, gingko, ginseng, cava,ginger root, yucca root, cassava root, poultry feed and many more.These spice mills provided with a set of perforated round holes screens, 3 meter cable with a plug and fitted with ampere meter,miniature circuit breaker for overload protection for motor and cotton balloons. Spice mills also equipped with special designed beaters, these spice mills are dynamically balanced rotor for less friction losses. Spices mills feature includes dust free operation thus does not waste product and cause no pollution hazards. Another feature of this mill is that effective and continuous crushing leads to increased production and faster return on investments.

Know how of spice mills

The flow of material from the feeding hopper is regulating by means of sliding gate to suit the load. Rotor is runs in anticlocKWise direction. The beaters pass just beneath the ratchet teeth liner fitted inside the top half of the crushing chamber, leaving a gap of 3 mm between the liner teeth and the tips of the rotating rotor. This cuts the material caught between the liner teeth like a sword with a scissors action at a high speed of 2880 rotations per minute. After the required size reduction, the material will pass through the screen fitted inside the lower discharge end of the grinding chamber.No sieving is required, as the appropriate size screen fitted will not allow coarser material to pass through. The air generated in the crushing chamber forces the powder to pass through the screen fitted at the bottom discharge end of the crushing chamber, into a filter attached to the delivery trough below. (When crushing wet-pulpy materials, the balloon should not be used

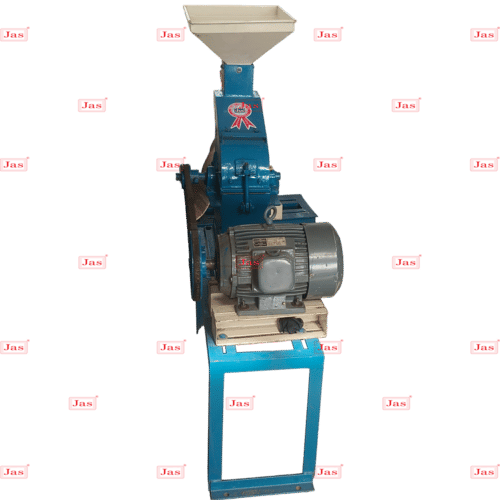

Product details

|

Power Consumption |

2 Kwh |

|

Type of Machine |

Hammer Mill |

|

Type of Masala |

Chilli,Coriander |

|

Material |

Stainless Steel |

|

Phase |

Single Phase |

|

Voltage (V) |

415V |

|

Speed (RPM) |

2800 Rpm |

|

Motor Power |

5 HP |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+