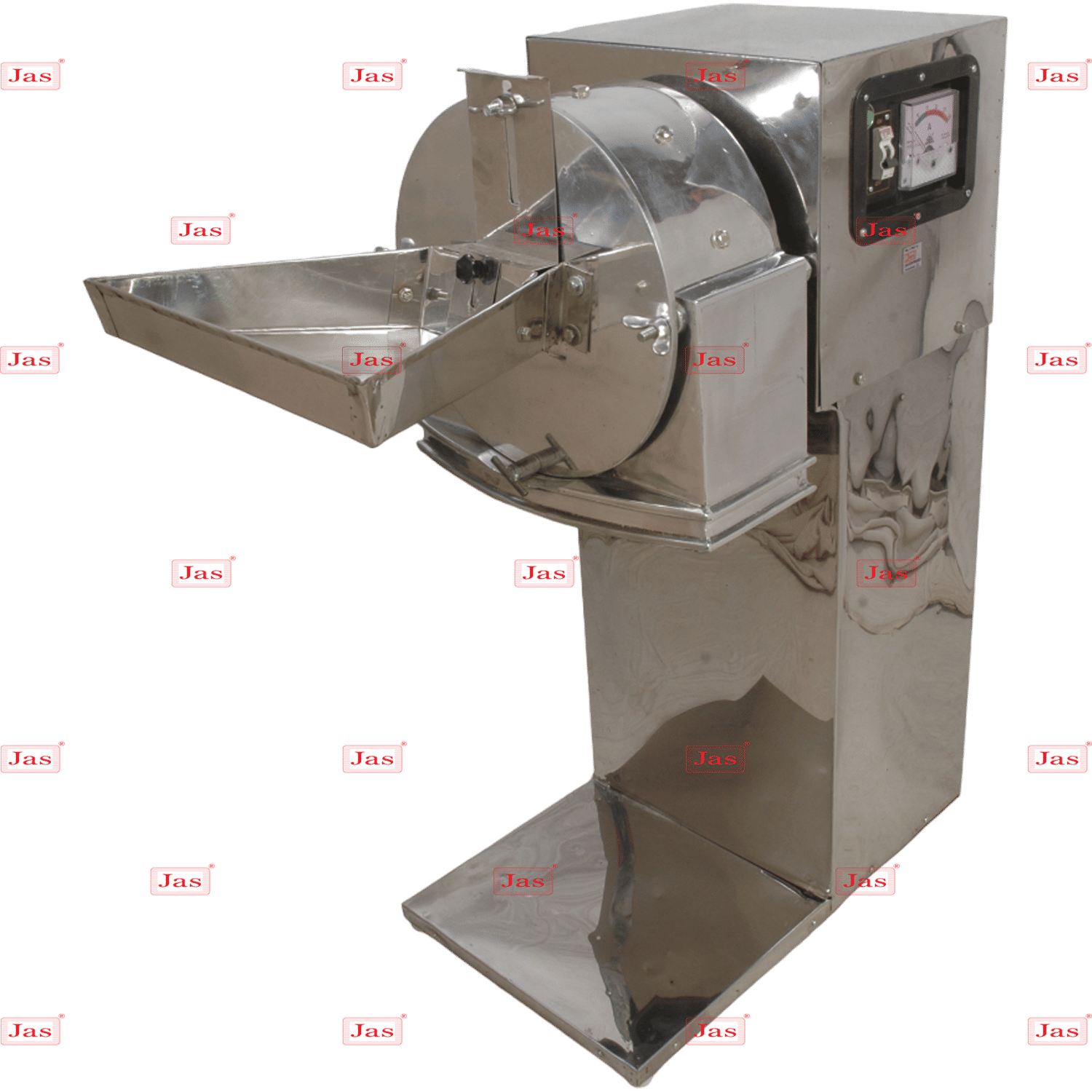

Herb Grinder

Price 56000 INR/ Unit

Herb Grinder Specification

- General Use

- Industrial

- Material

- Stainless Steel

- Capacity

- 30-160 Kg/hr

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC Control

- Voltage

- 230/440 Volt (v)

- Feature

- High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

- Color

- Sliver

- Warranty

- 1 Year

Herb Grinder Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Western Union, Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Herb Grinder

-

Material: Metal grinders (especially aluminum) are durable and often preferred, but plastic grinders are more affordable. Wooden grinders can be stylish and eco-friendly but may not be as durable.

-

Size: Grinders come in different sizes. A larger grinder can handle more material at once, but a smaller one is more portable.

-

Number of Chambers: Basic grinders have a single chamber, but multi-chamber grinders can separate the ground material from kief.

-

Teeth Design: The shape and arrangement of the teeth can affect how finely the herbs are ground.

-

Ease of Use and Cleaning: Look for a grinder thats easy to clean and use, as this can make a big difference in the long run.

Robust Industrial Design

Built entirely from high-grade stainless steel, this herb grinder is engineered for industrial applications, ensuring durability and hygiene. Its sturdy construction enables heavy-duty use, while its automatic operation streamlines workflow and minimizes manual intervention.

Advanced PLC Control

The integrated PLC control system offers precise automation, optimizing grinding operations and reducing human error. Operators can easily adjust settings to suit varying herb types or required granulation, delivering high efficiency and consistent quality output.

Energy Efficient & Eco-Friendly

Despite high-capacity operation, the grinder features low noise levels and reduced energy consumption. This eco-friendly design supports sustainable practices without sacrificing performance, making it a valuable asset for modern industrial facilities.

FAQs of Herb Grinder:

Q: How do you operate the Herb Grinder for optimal performance?

A: To achieve optimal results, simply set your desired parameters using the PLC control panel. Load the herbs into the hopper, and the automatic system will manage the grinding process, maintaining a consistent output between 30 and 160 kg per hour.Q: What types of herbs can be processed with this grinder?

A: This herb grinder is suited for a variety of dried herbs typically used in industrial processing, such as medicinal, culinary, or aromatic herbs. Its stainless steel body ensures safe and hygienic operation with different plant materials.Q: When should maintenance be performed on the grinder?

A: Routine cleaning after each use and scheduled maintenance, as outlined in the user manual, are recommended. With regular upkeep, the grinder delivers optimal performance throughout its 1-year warranty and beyond.Q: Where is the Herb Grinder most effectively used?

A: This machine is best utilized in industrial or commercial settings such as manufacturing plants, herb processing facilities, or wholesale operations across India, where high capacity and efficiency are essential.Q: What is the grinding process involved in this machine?

A: The herbs are loaded into the hopper, then ground automatically by the internal mechanisms controlled by the PLC system. The machine provides consistent, fine grinding with minimal manual intervention, ensuring product uniformity.Q: How does using this grinder benefit industrial operations?

A: The grinders high efficiency, low noise, and lower energy consumption translate to reduced operational costs. Additionally, its automatic operation and high-capacity output streamline production, improving profitability for industrial enterprises.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding, crushing and Pulverizing Machine Category

Jacketed Mini Pulverizer

Minimum Order Quantity : 01 Unit

Voltage : 110 to 415 Volt (v)

Warranty : 01 Year against manufacturing defects

Pulverizing Machine

Price 18000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Automatic : Yes

Capacity : 202200 Kg/hr

Warranty : 1 Year

Spice Mill

Price 15000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 415 Volt (v)

Automatic : Yes

Capacity : 3035 Kg/hr

Coriander Grinder Machine

Price 56000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220/440 Volt (v)

Automatic : No

Capacity : 30160 Kg/hr

Warranty : One year against manufacturing defect at our side

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free