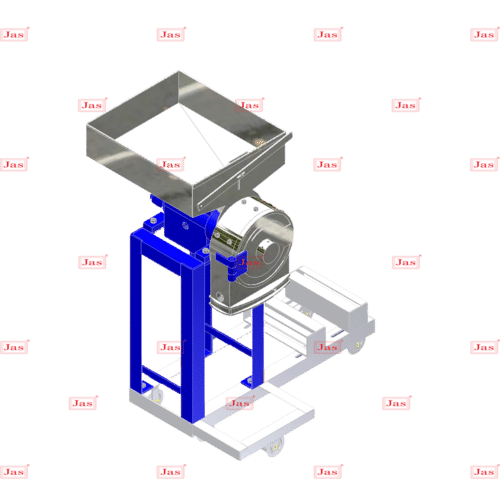

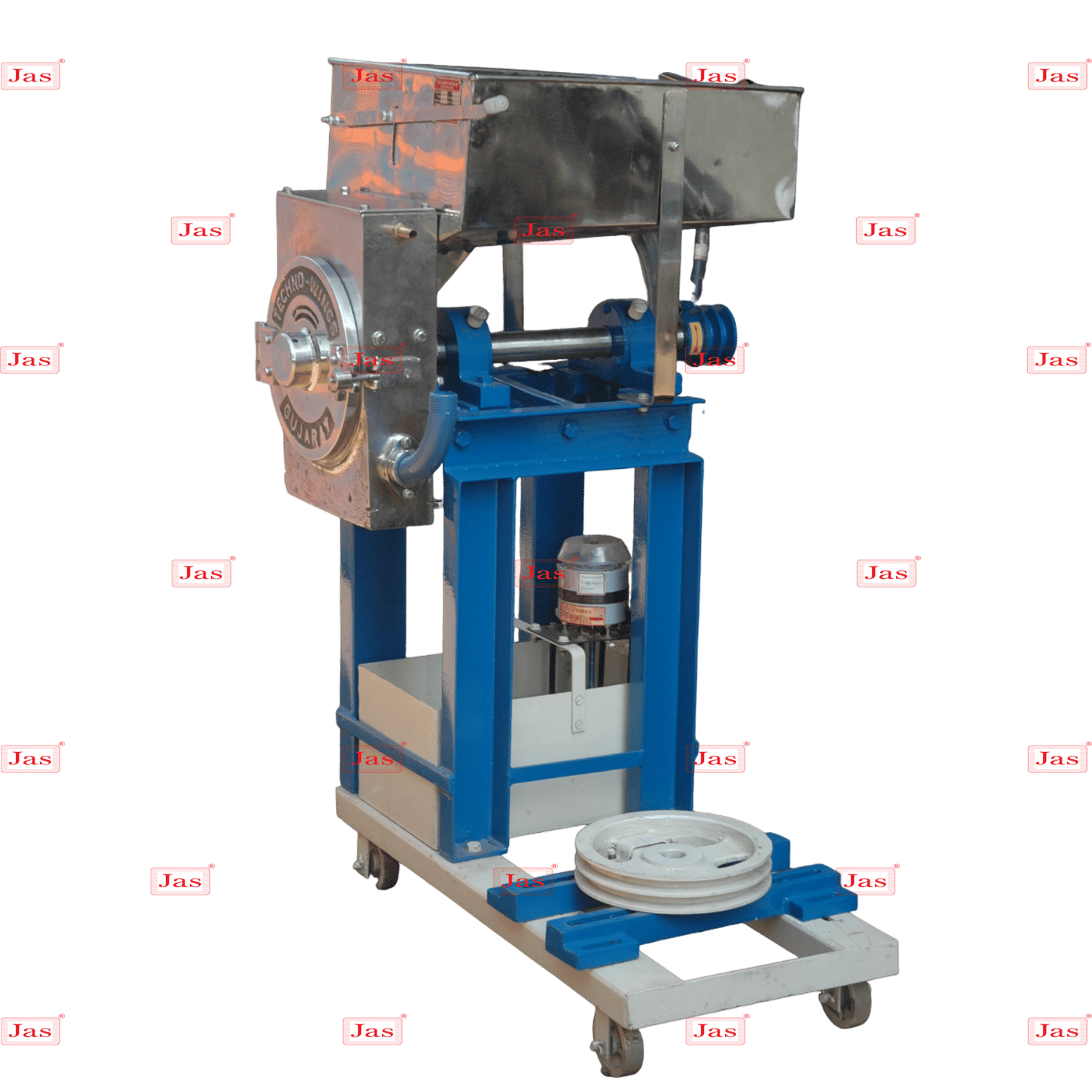

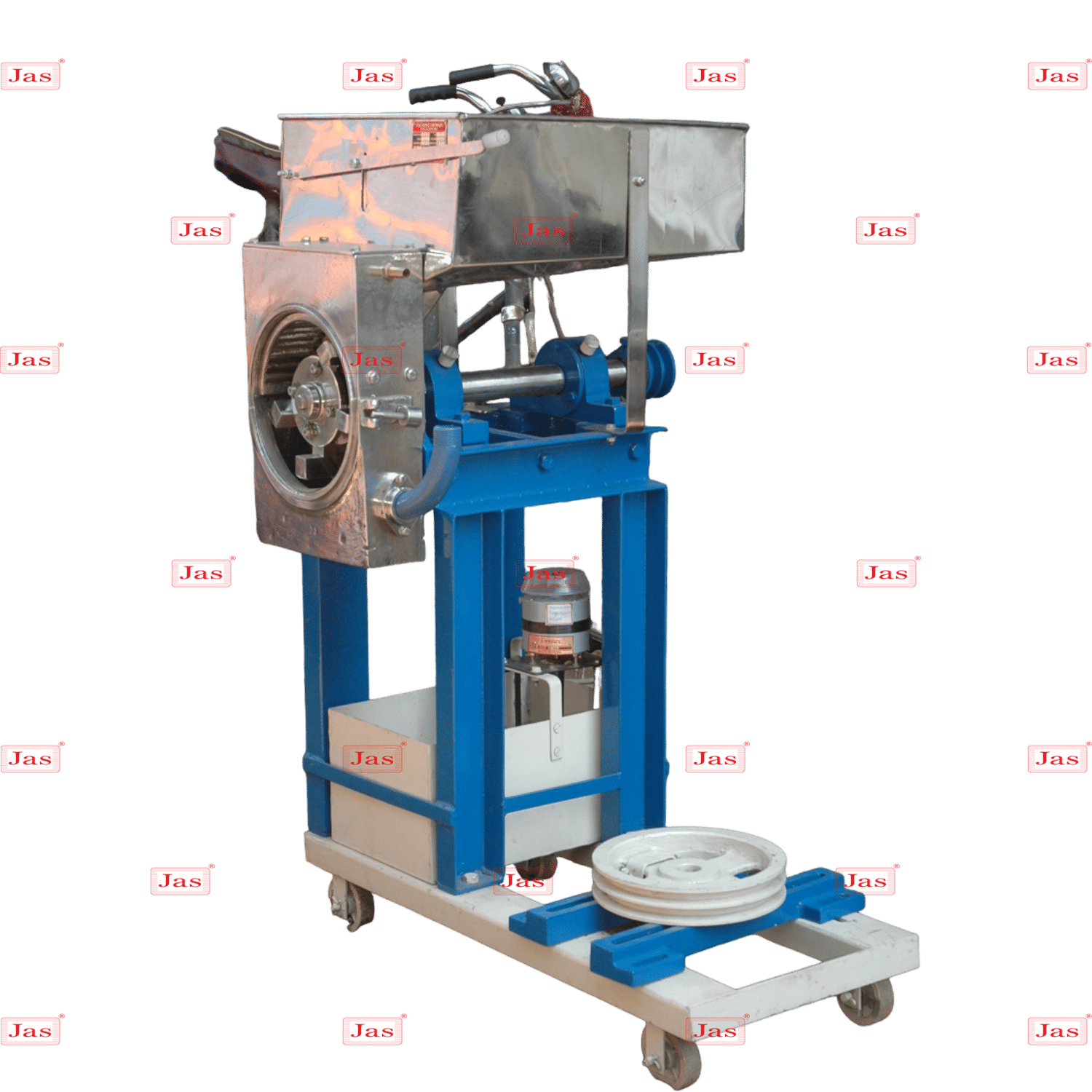

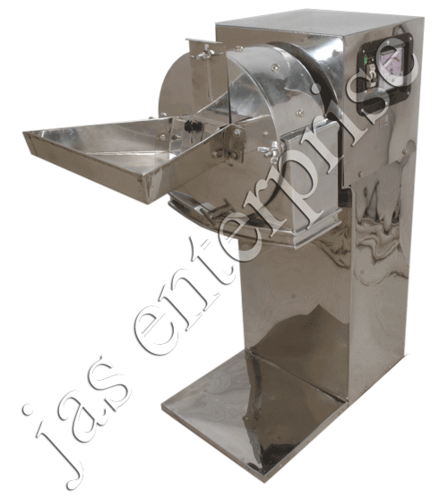

Semi Automatic Micro Pulverizer

Price 11500 INR/ Unit

Semi Automatic Micro Pulverizer Specification

- General Use

- Industrial

- Material

- Stainless Steel

- Computerized

- No

- Automatic

- No

- Voltage

- 230/440 Volt (v)

- Feature

- High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

- Warranty

- 1 Year

Semi Automatic Micro Pulverizer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Months

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Semi Automatic Micro Pulverizer

-

Grinding Mechanism: It employs a high-speed rotor assembly fitted with hammers or blades that pulverize the material fed into the grinding chamber.

-

Material Handling: Typically, materials are fed into the pulverizer manually or using a feeding mechanism. The machine then grinds these materials into a uniform powder.

-

Size Reduction: The primary function is size reduction, where larger particles or materials are reduced to smaller, consistent particle sizes suitable for various applications.

-

Operation: While semi-automatic, it often requires manual intervention for feeding materials and monitoring the process. However, certain aspects of the operation, such as grinding and discharging, may be automated.

-

Applications: It finds use in various industries such as food processing, pharmaceuticals, chemicals, and materials processing. Common applications include grinding spices, grains, herbs, plastics, and other similar materials.

-

Design and Construction: Typically compact and designed for ease of cleaning and maintenance. They are often constructed of stainless steel to meet hygiene and cleanliness standards in industries like food and pharmaceuticals.

-

Controls and Safety: Modern units may include control panels for adjusting operational parameters like speed and feed rate. Safety features ensure operator protection during operation.

Key Features & Performance

This micro pulverizer stands out for its exceptional performance, consuming less energy while producing minimal noise. The sturdy stainless steel construction ensures longevity and resistance to corrosion, making it suitable for continuous industrial use. Operators benefit from its efficient grinding capabilities and eco-friendly operation.

Versatility Across Industrial Sectors

With wide applicability in various industries, from pharmaceuticals to food processing, the Semi Automatic Micro Pulverizer offers flexibility for businesses that demand consistent milling results. Its semi-automatic design makes it accessible and straightforward to use, even in environments where computerized machines arent suitable.

FAQs of Semi Automatic Micro Pulverizer:

Q: How is the Semi Automatic Micro Pulverizer used in industrial settings?

A: The machine is primarily used for pulverizing, grinding, and reducing raw materials to finer particles. It is ideal for industries requiring uniform particle size, such as pharmaceuticals, food processing, and chemicals. Operation is straightforward, involving material feeding, controlled grinding, and easy collection of processed output.Q: What materials can be processed with this stainless steel pulverizer?

A: The pulverizer is suitable for a variety of materials, including spices, grains, chemicals, and certain pharmaceutical ingredients. Its stainless steel construction ensures contamination-free processing, especially for food and sensitive chemical applications.Q: When should this micro pulverizer be chosen over a fully automatic model?

A: This model is ideal when full automation isnt required and where manual oversight is preferred. It suits smaller-scale operations or environments with variable material inputs. The semi-automatic design is also appropriate for facilities aiming to minimize maintenance complexity and cost.Q: Where can I source the Semi Automatic Micro Pulverizer in India?

A: The machine is widely available throughout India via certified distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers. This broad network ensures accessibility and after-sales support, regardless of your region.Q: What is the process for operating and maintaining the pulverizer?

A: Operation involves loading the material, starting the machine, and monitoring output quality. Maintenance includes regular cleaning, periodic inspection of grinding components, and checking for wear. The stainless steel body facilitates easy hygiene management and longevity.Q: How does this pulverizer benefit my business compared to conventional models?

A: Its high performance, eco-friendly operation, and energy efficiency translate to lower operational costs. Reduced noise and easy maintenance support a healthier, more productive working environment. The 1-year warranty offers peace of mind regarding reliability and support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

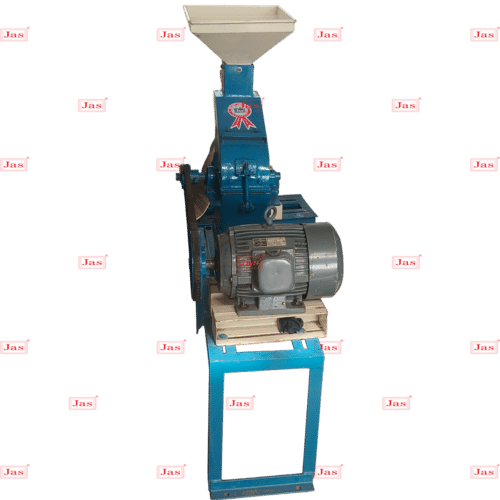

More Products in Grinding, crushing and Pulverizing Machine Category

Pulverizing Machine

Price 18000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 202200 Kg/hr

Automatic : Yes

Voltage : 230/440 Volt (v)

Impact Pulverizer

Price Range 18500.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 3035 Kg/hr

Automatic : Yes

Voltage : 110 to 415 Volt (v)

Pulverizer For Mineral Grinding

Price 18000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 202200 Kg/hr

Automatic : Yes

Voltage : 230/440 Volt (v)

Mill Masala Mill

Price Range 15000.00 - 145000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 30 to 160 Kg/hr

Automatic : Yes

Voltage : 110 440 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free