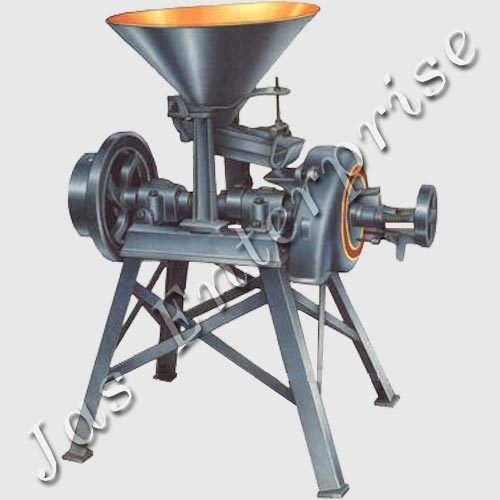

Multipurpose Dry and Wet Pulverizer

25000 INR/Unit

Product Details:

- Material Stainless Steel

- Weight (kg) 65 Kilograms (kg)

- Automatic Yes

- Power 1500 Watt (w)

- Voltage 110 to 415 Volt (v)

- Dimension (L*W*H) 62 X 32 X 77 Centimeter (cm)

- Click to View more

X

Multipurpose Dry and Wet Pulverizer Price And Quantity

- 1 Piece

- 25000 INR/Unit

Multipurpose Dry and Wet Pulverizer Product Specifications

- 65 Kilograms (kg)

- Stainless Steel

- Yes

- 62 X 32 X 77 Centimeter (cm)

- 1500 Watt (w)

- 110 to 415 Volt (v)

Multipurpose Dry and Wet Pulverizer Trade Information

- 1000 Piece Per Month

- Week

Product Description

Taken quality as a prime concern, we are involved in manufacturing and exporting tough built Multipurpose Pulverizer. To meet the international quality standards, this pulverizer is manufactured using high grade stainless steel that is procured from certified vendors of the market. Our offered pulverizer is thoroughly examined on various factors like superior finish and high strength. This Multipurpose Pulverizer is widely used for grinding various types of spices, sugar, betel nuts, poultry feeds and for allied food production.Striking characteristics:

- Simple installation

- Seamless finish

- Longer service life

- Rugged construction

Other details:

Key features of dry and wet pulverizer

- Unique and reliable design

- The multipurpose dry and wet pulverizers are highly effective as well as nonstop continuous pulverizing process.

- All contacting parts are aluminum and stainless steel no corrosion hazards.

- Multipurpose dry and wet pulverizers is not required any v belts thus less friction losses.

- Increased production leading to faster return on the investments

- All rotating parts are dynamical balanced for less vibration and higher performances.

- Low temperature grinding Jaslogy thus the original ingredient cannot destroy.

Application of dry and wet pulverizer

Multipurpose dry and wet pulverizers are exclusively meant for the grinding of wheat, maize, oat, pulses, other grains, chili, coriander, dry ginger, black pepper, turmeric and curry powders, tomato, wet rice, pulses, etc.. on a small scale basis.

Construction of dry and wet pulverizer

Multipurpose dry and wet pulverizers made from heavy duty mild steel fabricated body covered with stainless steel sheet. Aluminum grinding chamber lined with serrated wear steel plates, which protects the body from wear and tear. Grinding is done by a set of fixed better on a balanced rotor. A screen classifier forms the lower half of the grinding chamber.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email