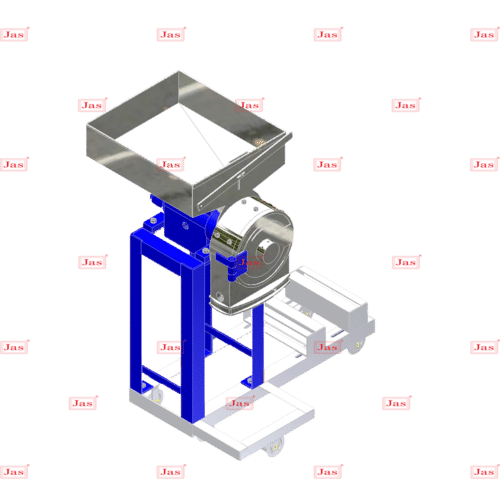

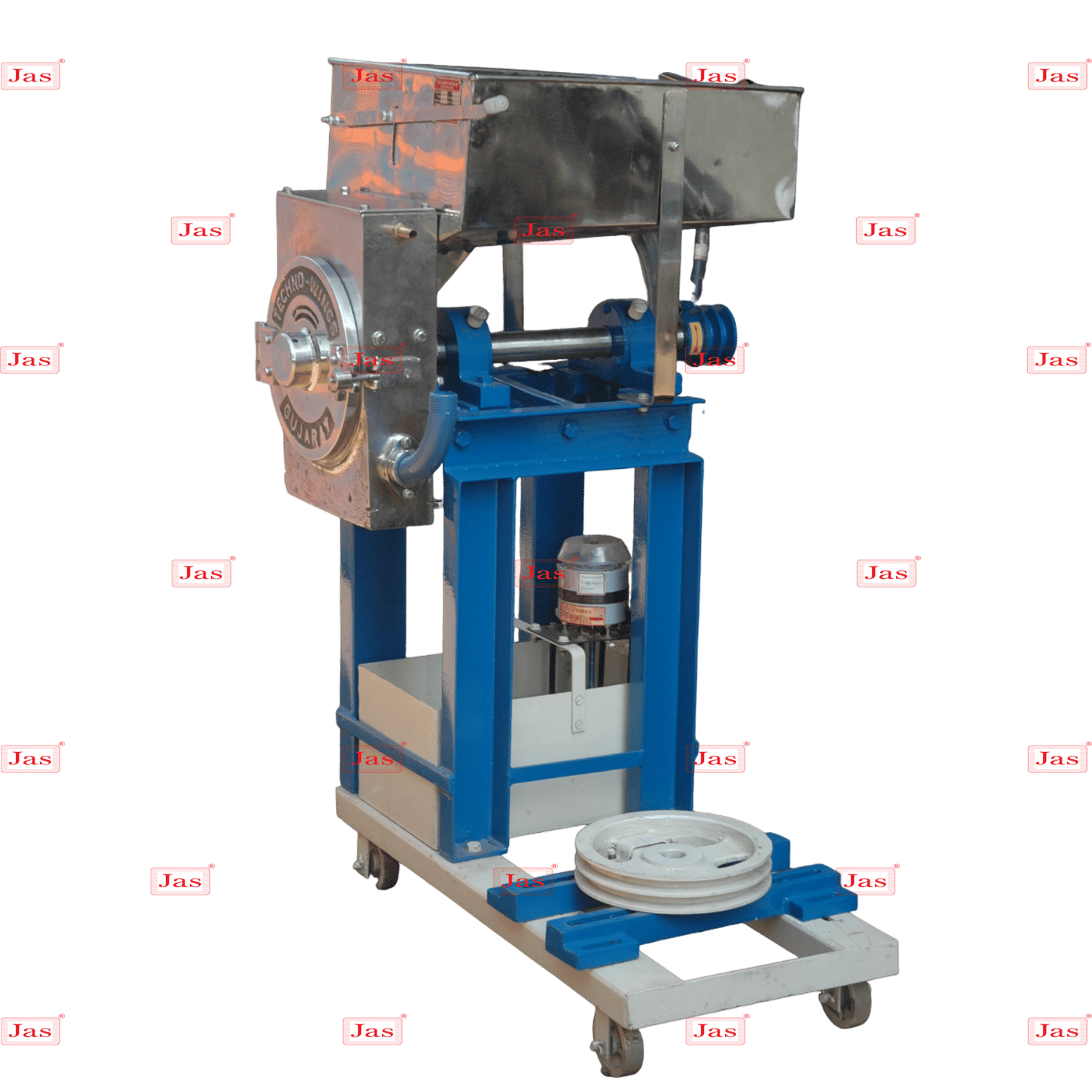

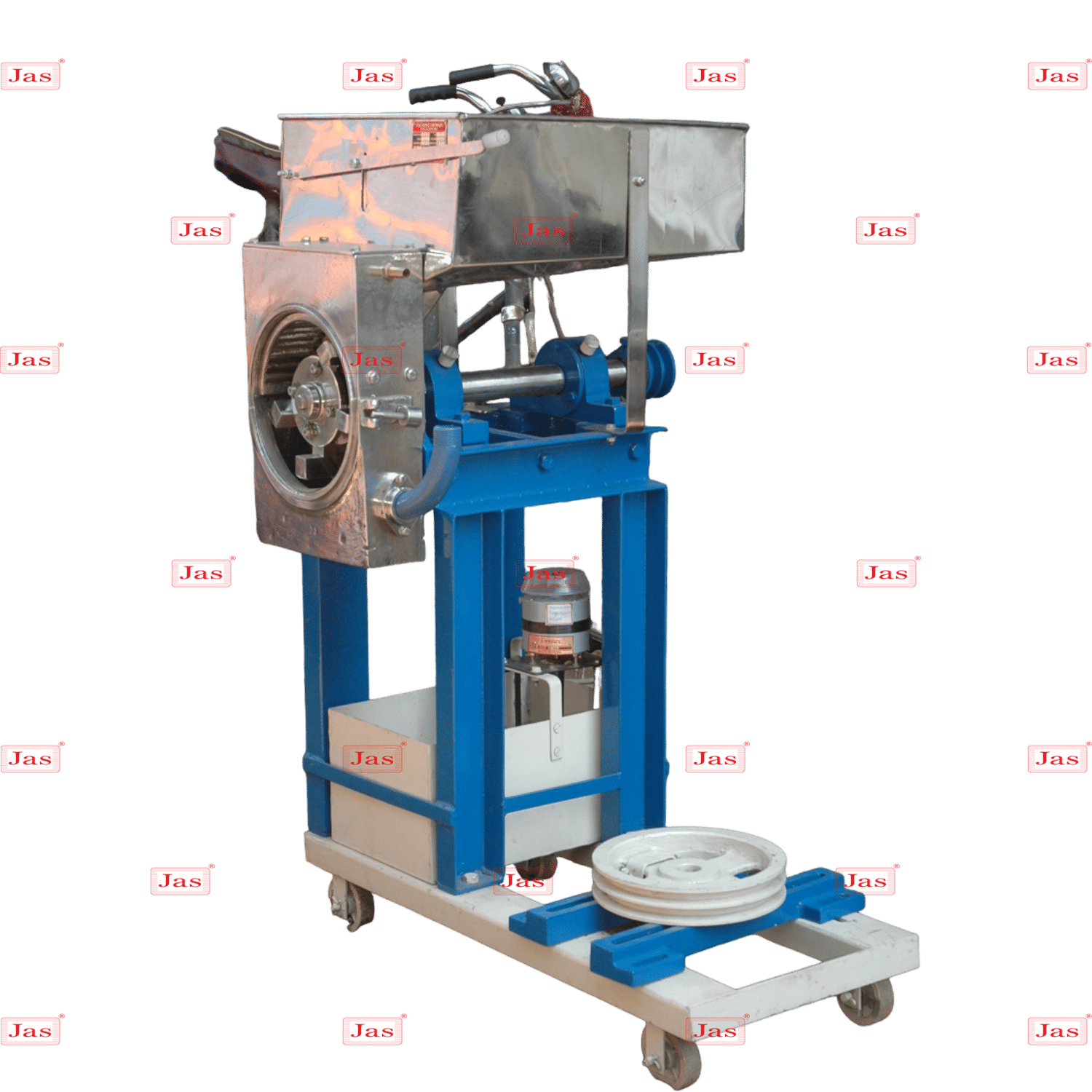

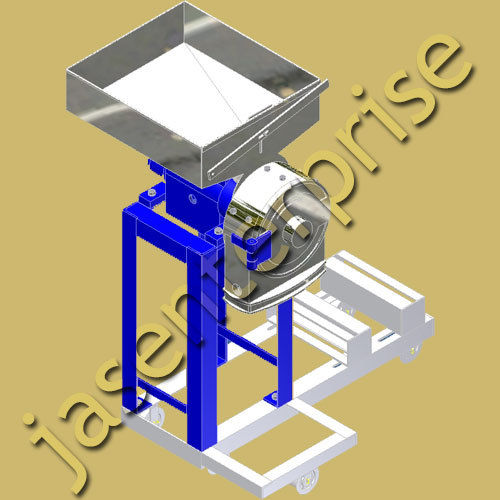

Semi Automatic Micro Pulverizer

उत्पाद विवरण:

- सामान्य उपयोग Industrial

- मटेरियल

- कम्प्यूटरीकृत

- ऑटोमेटिक

- वोल्टेज वोल्ट (v)

- फ़ीचर

- वारंटी 1 Year

- अधिक देखने के लिए क्लिक करें

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- Industrial

- 1 Year

- वोल्ट (v)

व्यापार सूचना

- प्रति महीने

- महीने

- ISO

उत्पाद वर्णन

-

Grinding Mechanism: It employs a high-speed rotor assembly fitted with hammers or blades that pulverize the material fed into the grinding chamber.

-

Material Handling: Typically, materials are fed into the pulverizer manually or using a feeding mechanism. The machine then grinds these materials into a uniform powder.

-

Size Reduction: The primary function is size reduction, where larger particles or materials are reduced to smaller, consistent particle sizes suitable for various applications.

-

Operation: While semi-automatic, it often requires manual intervention for feeding materials and monitoring the process. However, certain aspects of the operation, such as grinding and discharging, may be automated.

-

Applications: It finds use in various industries such as food processing, pharmaceuticals, chemicals, and materials processing. Common applications include grinding spices, grains, herbs, plastics, and other similar materials.

-

Design and Construction: Typically compact and designed for ease of cleaning and maintenance. They are often constructed of stainless steel to meet hygiene and cleanliness standards in industries like food and pharmaceuticals.

-

Controls and Safety: Modern units may include control panels for adjusting operational parameters like speed and feed rate. Safety features ensure operator protection during operation.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+