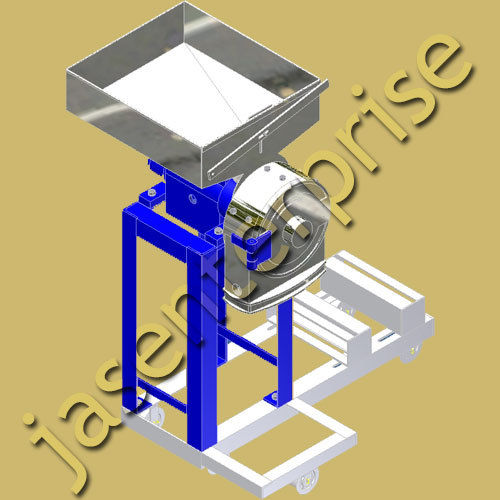

Semi Automatic Flour Mill

29000 INR/Unit

Product Details:

- Capacity 30-170 Kg/hr

- Automatic Yes

- Voltage 230/440 Volt (v)

- Feature High Performance ECO Friendly Low Noise Lower Energy Consumption High Efficiency

- Click to View more

X

Semi Automatic Flour Mill Price And Quantity

- 29000 INR/Unit

- 29000.00 - 89000.00 INR/Unit

- 1 Unit

Semi Automatic Flour Mill Product Specifications

- High Performance ECO Friendly Low Noise Lower Energy Consumption High Efficiency

- Yes

- 230/440 Volt (v)

- 30-170 Kg/hr

Semi Automatic Flour Mill Trade Information

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque Western Union

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- ISO

Product Description

Features:

Motorized Grinding Mechanism: Uses an electric motor to drive the grinding stones or rollers, which reduces the manual effort required for milling.

Hopper and Feed System: Includes a hopper where grains are loaded, and a feed system that automatically moves the grains to the grinding area.

Adjustable Settings: Allows users to adjust the fineness of the flour by changing the distance between the grinding stones or rollers.

Output Control: Provides control over the flow of flour, often with a collection bin or bagging system to collect the processed flour.

Cleaning Mechanism: Some models come with features for easy cleaning, such as detachable parts or brushes.

Safety Features: Includes safety mechanisms to prevent accidents, like emergency stop buttons and guards around the grinding area.

Benefits:

Efficiency: Increases milling efficiency by automating parts of the process, which can be especially useful for small to medium-scale operations.

Consistency: Offers more consistent flour quality compared to fully manual mills, thanks to controlled grinding settings.

Labor Saving: Reduces the amount of manual labor required, making it easier to operate and manage.

Versatility: Can often process various types of grains, such as wheat, rice, and corn, depending on the design.

Cost-Effective: More affordable than fully automatic mills while still offering significant improvements over manual grinding.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email