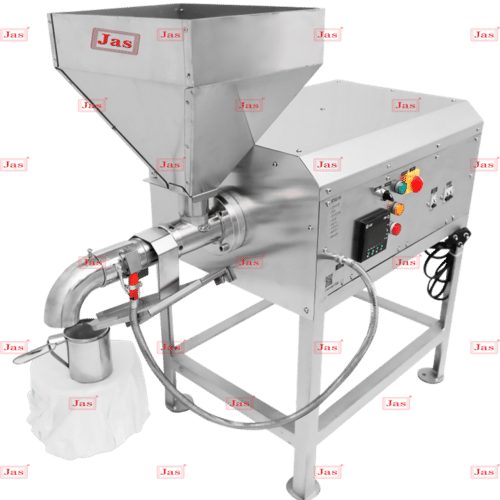

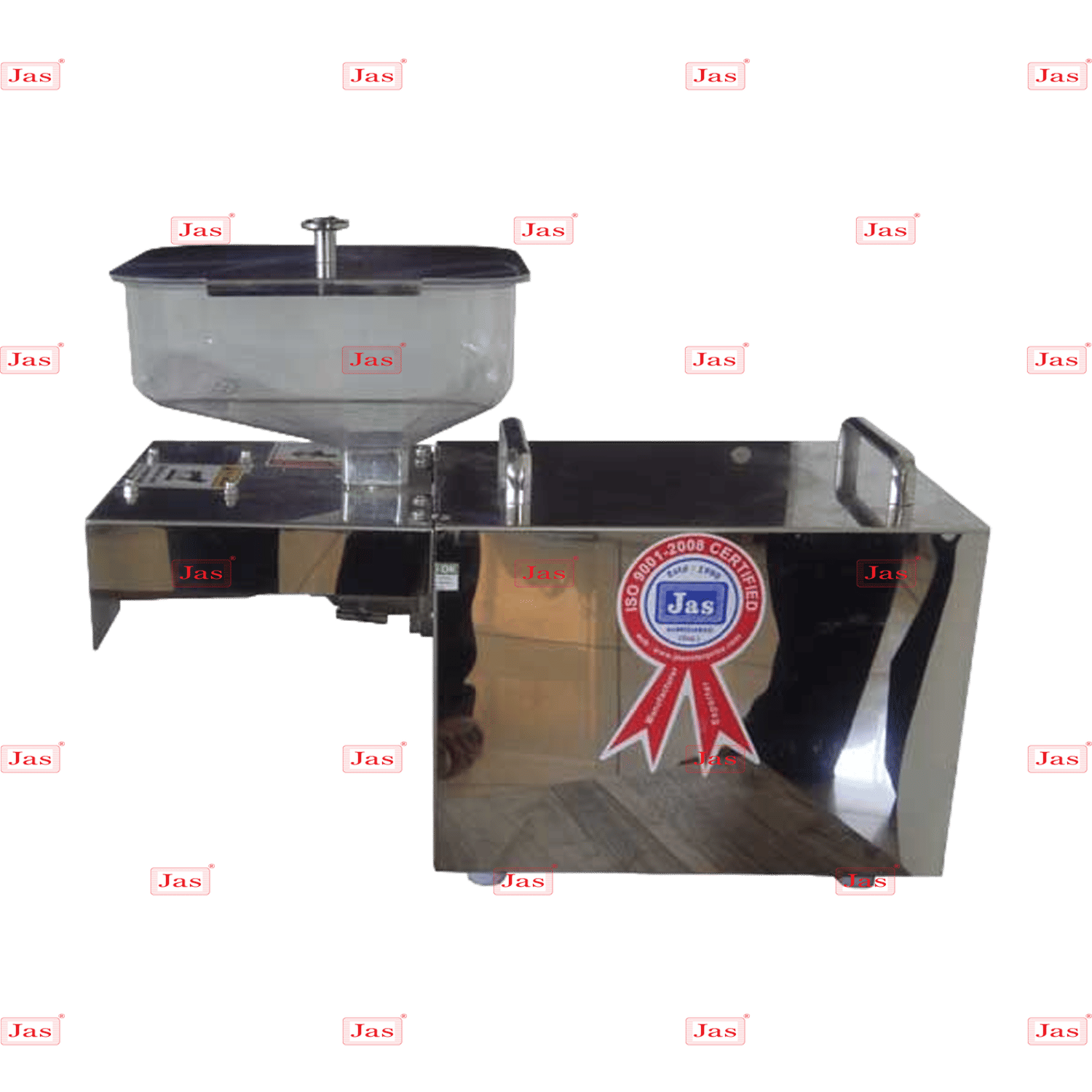

Herbal Oil Extraction Machine

Price 16000 INR/ Unit

Herbal Oil Extraction Machine Specification

- Automation Grade

- Automatic

- Power Source

- Electric

- Material

- Stainless Steel

- Capacity

- 2-25 Kg/hr

- Computerized

- No

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Color

- Other

- Warranty

- 1 Year

Herbal Oil Extraction Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Herbal Oil Extraction Machine

Cold Press Extraction Machines- Method Uses mechanical pressure to squeeze out the oil without applying heat

- Advantages Preserves the natural qualities and aroma of the essential oils

- Applications Commonly used for extracting oils from citrus fruits like oranges and lemons and some nuts and seeds

2 Steam Distillation Units

- Method Uses steam to vaporize the essential oils which are then condensed back into liquid form

- Advantages Effective for extracting essential oils from herbs flowers and leaves

- Applications Widely used for distilling oils like lavender peppermint and rosemary

3 Solvent Extraction Machines

- Method Uses chemical solvents to dissolve essential oils from plant material followed by the removal of the solvent

- Advantages Can extract oils from delicate flowers and other materials where other methods might not be as effective

- Applications Often used for extracting jasmine vanilla and other highvalue essential oils

4 CO2 Extraction Machines

- Method Uses supercritical carbon dioxide to extract essential oils The CO2 is pressurized and heated until it reaches a state where it can act as a solvent

- Advantages Provides a high yield and preserves a wide range of plant compounds Its also considered to be a cleaner process compared to solvent extraction

- Applications Suitable for highquality essential oils such as those used in highend cosmetics and aromatherapy products

5 Hydrodistillation Units

- Method A combination of steam and boiling water is used to extract essential oils

- Advantages Suitable for plant materials that require prolonged boiling

- Applications Used for herbs and plants where gentle boiling is necessary

Efficient Herbal Oil Extraction with Automation

This herbal oil extraction machine delivers automatic operation, optimizing productivity while keeping manual intervention minimal. Its 230/440 Volt electric power source and robust stainless steel construction ensure durability and consistent performance. Ideal for herbal product manufacturers and retailers requiring a streamlined setup.

Eco-Friendly and Cost-Effective

Designed with environmentally conscious technology, the machine consumes less energy and operates with low noise. The compact structure makes it suitable for installations with limited space, without compromising on extraction capacity or quality. Efficient resource usage also helps lower operational costs.

FAQs of Herbal Oil Extraction Machine:

Q: How does the Herbal Oil Extraction Machine operate automatically?

A: The machine features a fully automatic system that streamlines the entire extraction process, minimizing the need for manual supervision. Simply load the desired quantity of herbs, set the appropriate parameters, and the machine efficiently handles the extraction cycle.Q: What materials are suitable for extraction with this machine?

A: This equipment is designed to process a wide variety of herbs for oil extraction, handling 225 kg per hour. Its stainless steel build ensures it can withstand various herb types, delivering purity and maintaining product quality.Q: When should maintenance be performed on this machine?

A: Routine maintenance is recommended every few months, depending on usage intensity. Regular cleaning and inspection of components help ensure optimal performance and longevity. The machines robust build and one-year warranty further minimize maintenance concerns.Q: Where can this machine be installed or utilized?

A: Its compact structure allows for easy installation in different production environments, including manufacturing units, retail spaces, and even smaller-scale facilities. The machine is distributed and supplied throughout India, adaptable to diverse operational settings.Q: What is the operational process of oil extraction using this machine?

A: To extract oil, simply load the herbs, set the extraction parameters, and turn on the machine. The automatic system manages the extraction process, separating oil from herbs efficiently and with minimal effort required from the operator.Q: How does this machine benefit users in terms of efficiency and cost savings?

A: It delivers high efficiency through its automated operation, low energy consumption, and fast processing rate. This results in reduced labor costs, lower electricity bills, and faster turnaround times, making it a cost-effective solution for herbal oil producers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oil Mill, Oil Extraction Machinery & Equipment Category

Oil Mill Oil Extraction Machinery and Equipment

Price 20000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One year against manufacturing defects at our site

Capacity : 8 Kg/hr

Automatic : Yes

Flaxseed Oil Extraction Machine

Price Range 20000.00 - 130000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One year against manufacturing defects at our site, except all wear and tear parts.

Capacity : 2 to 20 Kg/hr

Automatic : Yes

Commercial Automatic Copra Cutter

Price 11000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : One year against manufacturing defects at our site, except all wear and tear parts.

Ayurvedic Seeds Oil Extraction Machine

Price Range 20000.00 - 130000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One year against manufacturing defects at our site, except all wear and tear parts.

Capacity : 2 to 20 Kg/hr

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS