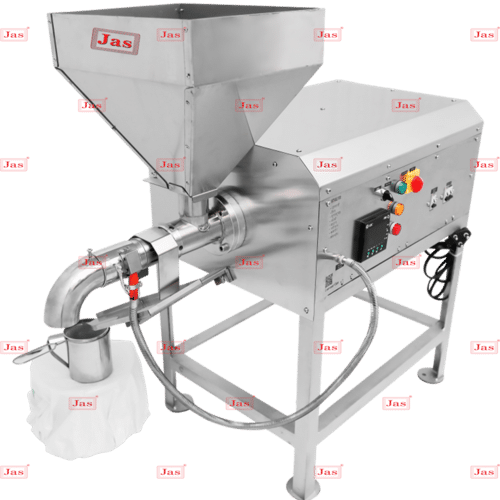

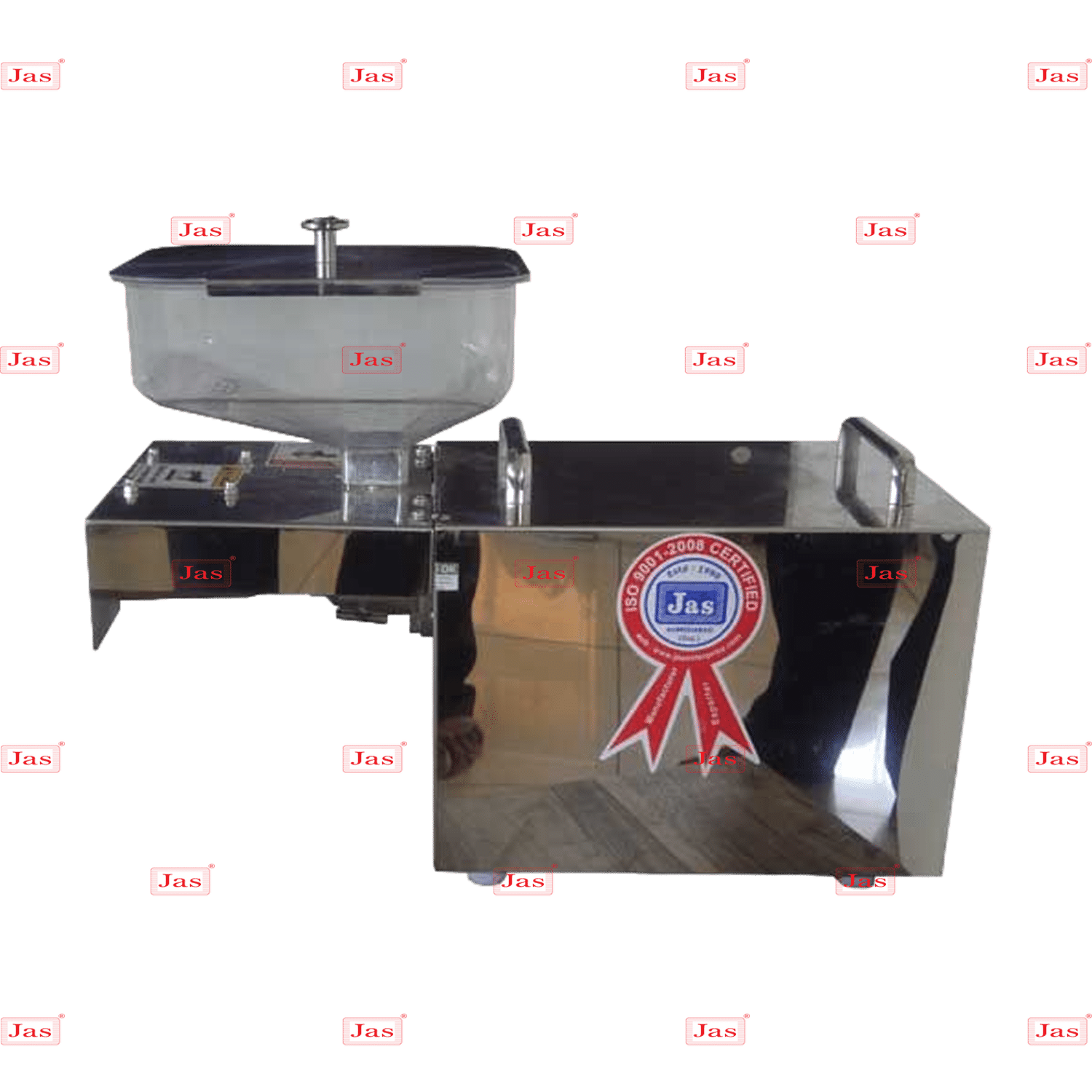

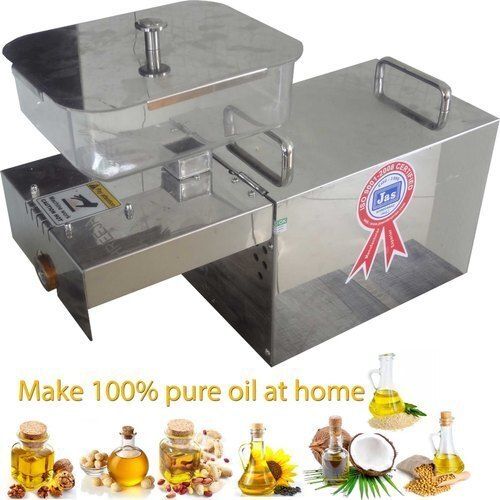

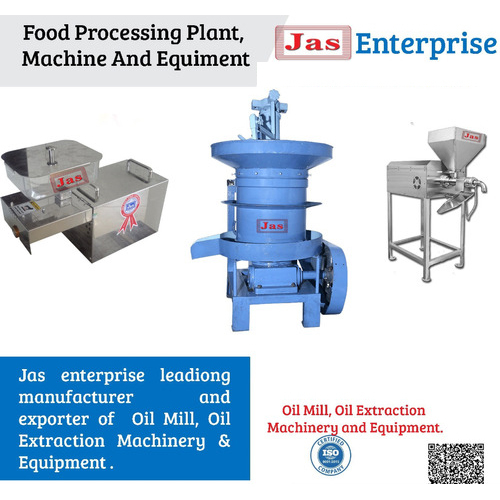

Vegetable Oil Extraction Machine

16000 INR/Unit

Product Details:

- Capacity 2-25 Kg/hr

- Automatic Yes

- Voltage 230/440 Volt (v)

- Feature ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- Click to View more

X

Vegetable Oil Extraction Machine Price And Quantity

- 1 Unit

- 16000 INR/Unit

- 16000.00 - 160000.00 INR/Unit

Vegetable Oil Extraction Machine Product Specifications

- 230/440 Volt (v)

- Yes

- ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- 2-25 Kg/hr

Vegetable Oil Extraction Machine Trade Information

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- ISO

Product Description

Types of Vegetable Oil Extraction Machines

-

Expeller Presses:

- Cold Press: Extracts oil without heating, preserving the nutritional quality and flavor of the oil.

- Hot Press: Uses heat to extract more oil and increase efficiency but may affect the oil's quality.

-

Solvent Extractors:

- Utilizes solvents like hexane to dissolve and extract oil from the seeds or nuts. After extraction, the solvent is evaporated, leaving behind the oil.

-

Hydraulic Presses:

- Uses hydraulic pressure to squeeze oil from seeds. Typically used for smaller scale operations or high-quality, artisanal oils.

-

Screw Presses:

- Employs a screw mechanism to press oil from seeds. This is a common choice for larger scale operations due to its efficiency.

Key Components

- Feeder: Introduces the seeds into the machine.

- Crushing Chamber: Breaks down the seeds to prepare them for extraction.

- Pressing Chamber: Where the actual extraction takes place, using mechanical force or heat.

- Filter: Removes impurities and particulates from the extracted oil.

- Oil Cake Outlet: The byproduct of the extraction process, which can be used as animal feed or compost.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email