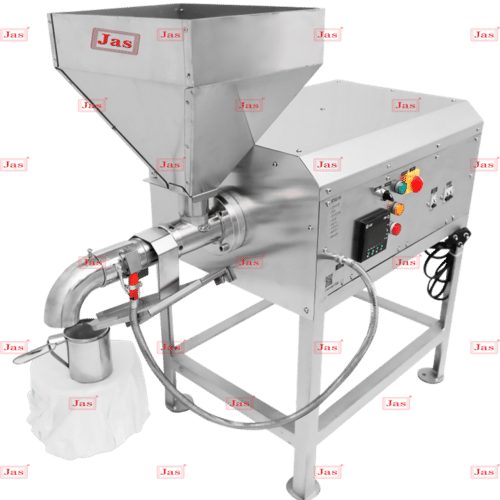

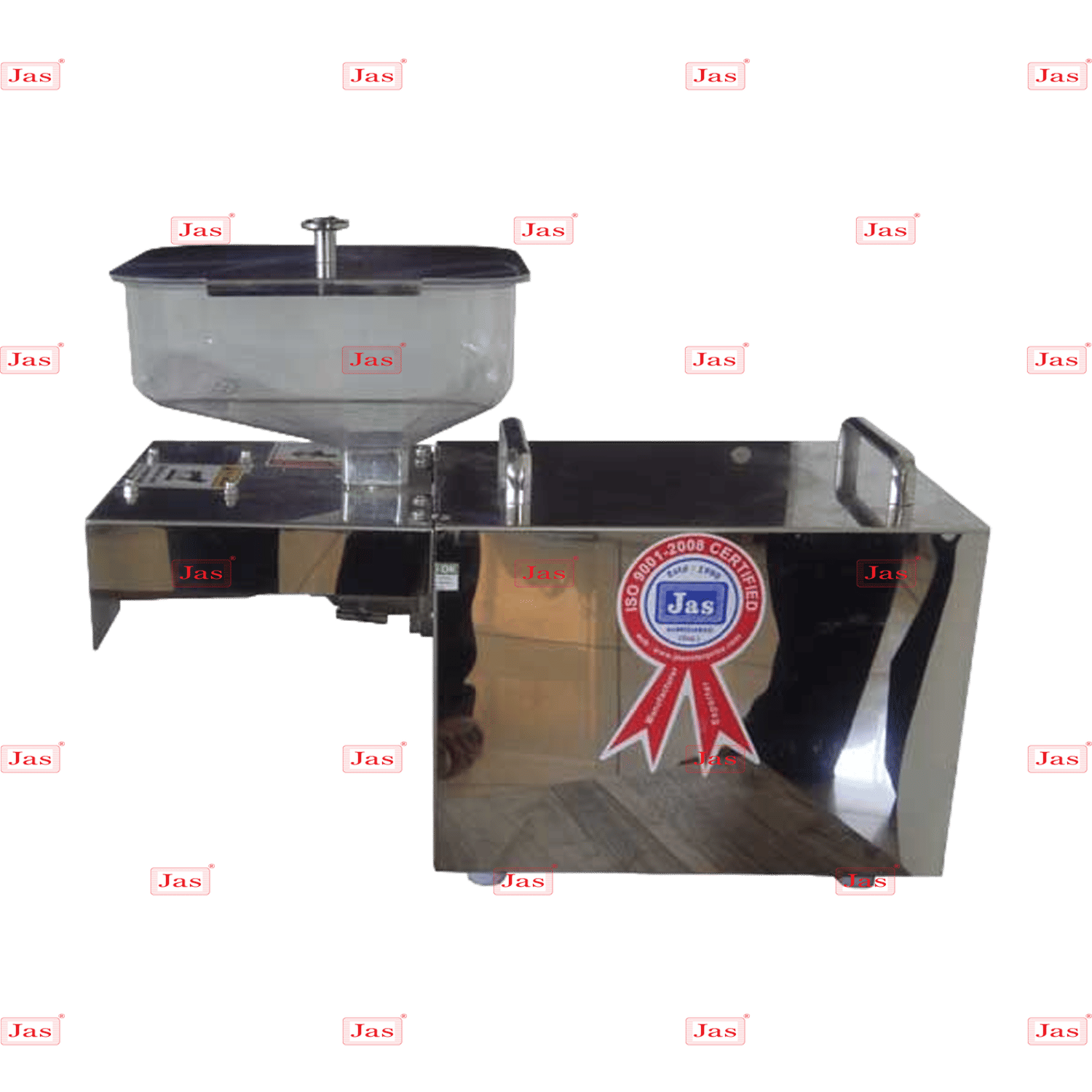

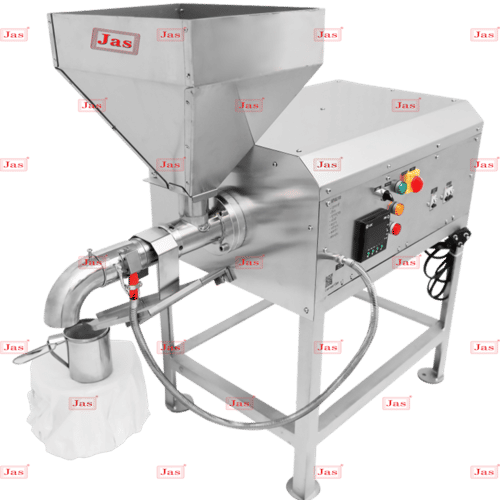

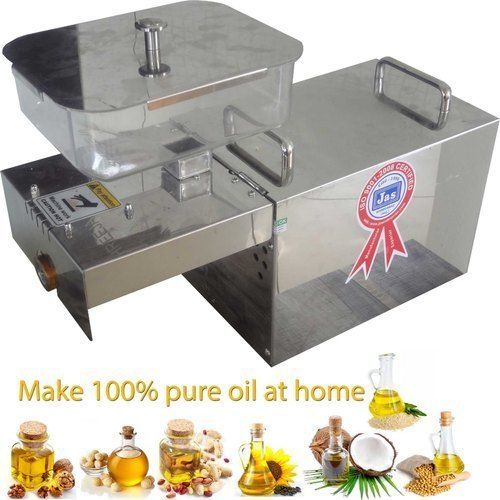

Herbal Oil Extraction Machine

16000 आईएनआर/Unit

उत्पाद विवरण:

- ऑटोमेशन ग्रेड Automatic

- पावर सोर्स Electric

- मटेरियल

- क्षमता किलो/घंटा

- कम्प्यूटरीकृत

- ऑटोमेटिक

- वोल्टेज वोल्ट (v)

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- 1 Year

- वोल्ट (v)

- Electric

- , ,

- Automatic

- किलो/घंटा

व्यापार सूचना

- , , , , , , , ,

- , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ,

- ISO

उत्पाद वर्णन

Cold Press Extraction Machines- Method Uses mechanical pressure to squeeze out the oil without applying heat

- Advantages Preserves the natural qualities and aroma of the essential oils

- Applications Commonly used for extracting oils from citrus fruits like oranges and lemons and some nuts and seeds

2 Steam Distillation Units

- Method Uses steam to vaporize the essential oils which are then condensed back into liquid form

- Advantages Effective for extracting essential oils from herbs flowers and leaves

- Applications Widely used for distilling oils like lavender peppermint and rosemary

3 Solvent Extraction Machines

- Method Uses chemical solvents to dissolve essential oils from plant material followed by the removal of the solvent

- Advantages Can extract oils from delicate flowers and other materials where other methods might not be as effective

- Applications Often used for extracting jasmine vanilla and other highvalue essential oils

4 CO2 Extraction Machines

- Method Uses supercritical carbon dioxide to extract essential oils The CO2 is pressurized and heated until it reaches a state where it can act as a solvent

- Advantages Provides a high yield and preserves a wide range of plant compounds Its also considered to be a cleaner process compared to solvent extraction

- Applications Suitable for highquality essential oils such as those used in highend cosmetics and aromatherapy products

5 Hydrodistillation Units

- Method A combination of steam and boiling water is used to extract essential oils

- Advantages Suitable for plant materials that require prolonged boiling

- Applications Used for herbs and plants where gentle boiling is necessary

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें