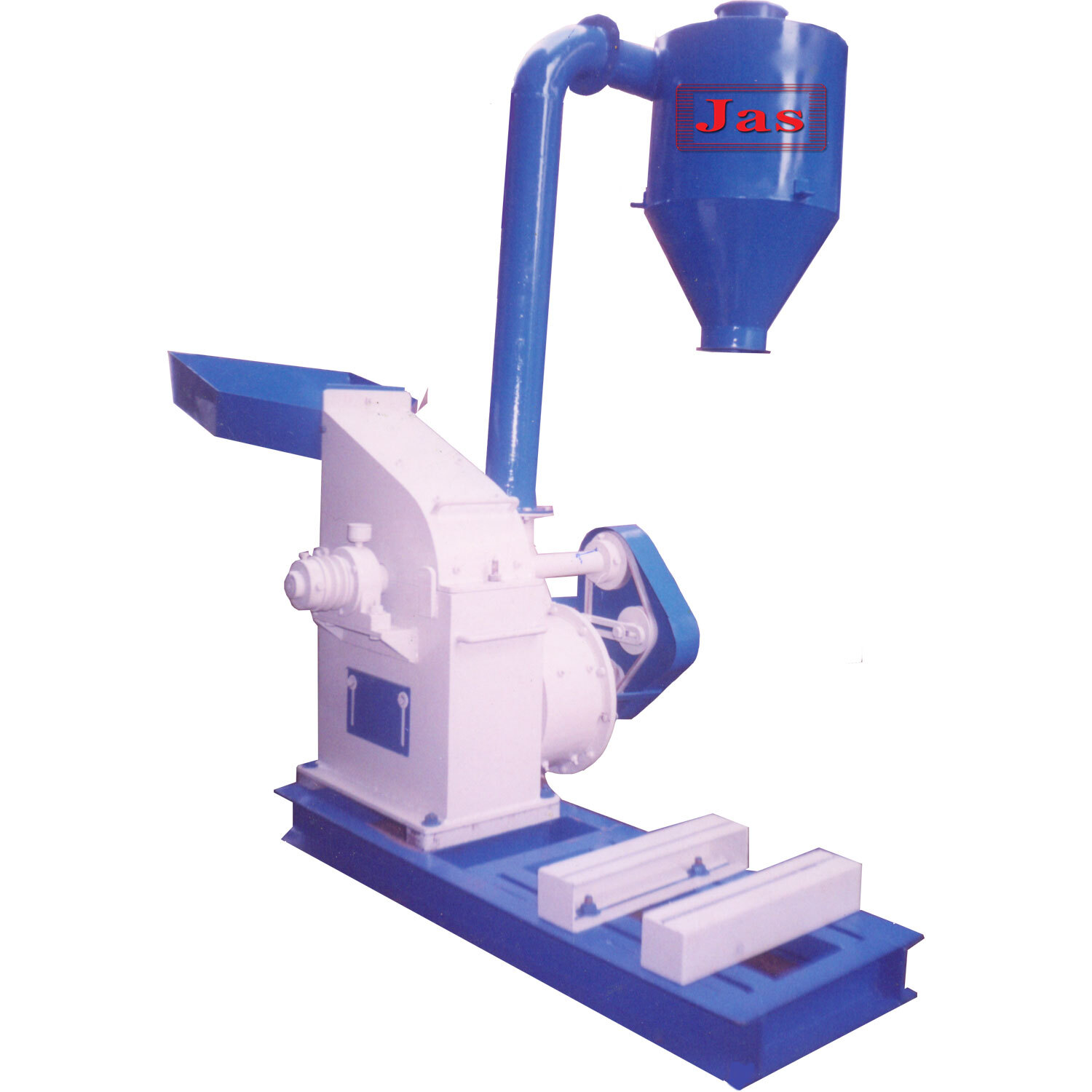

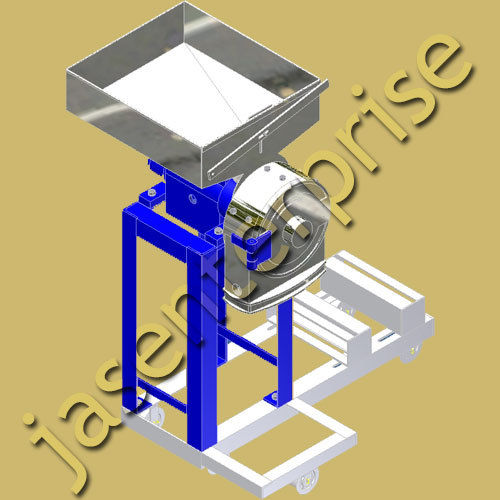

Auto Suction Hammer Mill

18500.00 - 125000.00 INR/Unit

Product Details:

- Material Stainless Steel

- Weight (kg) 65 Kilograms (kg)

- Automatic Yes

- Power 3000 to 7000 Watt (w)

- Voltage 110 to 415 Volt (v)

- Color Blue

- Click to View more

X

Auto Suction Hammer Mill Price And Quantity

- 1 Unit

- 18500.00 - 125000.00 INR/Unit

Auto Suction Hammer Mill Product Specifications

- Yes

- 3000 to 7000 Watt (w)

- 110 to 415 Volt (v)

- Stainless Steel

- 65 Kilograms (kg)

- Blue

Auto Suction Hammer Mill Trade Information

- Ahmedabad

- 1000 Unit Per Month

- Week

- Sample costs shipping and taxes has to be paid by the buyer

- Australia North America Eastern Europe Western Europe Middle East Africa Central America Asia

Product Description

Listed among the most leading organizations, we are engaged in manufacturing and exporting sturdily built Auto Suction Hammer Mill. This mill is manufactured using premium quality raw materials and other components that are procured from certified vendors of the market. Our offered mill is designed in various grades, models and specifications as demanded by our esteemed clients. We thoroughly check this Auto Suction Hammer Mill on various parameters like seamless finish and high performance.

Various characteristics:

- High tensile strength

- Superior finish

- Easy installation

- Low maintenance cost

Operating principle of auto suction hammer mill

The materials to be ground into the crushing chamber of auto suction hammer mill from feed hopper by gravity or through an automatic rotary feeder the carbides blades inside the crushing chamber accelerate the material to a very high speed to the toothed liner placed at the upper half of the crushing chamber. Shearing pulverizes the material. The ground materials are continuously sucked by a centrifugal blower through screens placed at the bottom periphery of the crushing chamber and conveyed through a pipe into the cyclone dust collector for bagging. Excess air filtered through an air classifier. Particle size varied using screens with different size holes.

Key features of auto suction hammer mill:

- Less operating cost due to automatic rotary tank feeding.

- Easy to operate and collect ground material without air pressure, due to specialized cyclone and dust collector.

- Due to availability of beater carbides in automatic suction hammer mills, it is not necessary to change beater frequently, which also ensures that production is not affected.

- Separate motor for hammer mill, blower, and rotary feeder, thus RPM of blower or hammer mill and ampere of motors does not fluctuate, hence increasing the working capacity of machine.

Construction of auto suction hammer mill:

Rotary feeder is supplied with gear box. Hammer mill made from heavy duty mild steel fabricated body. Grinding chamber lined with serrated wear plates, which protects the body from wear and tear. Grinding is done by a set of swinging blades or hammers on a balanced rotor. A screen classifier forms the lower half of the grinding chamber. Blower is driven on a separate shaft with the help of a belts and separate motor.

Product details

|

Country of Origin |

Made in India |

|

Automation Grade |

Automatic |

|

Phase |

Three Phase |

|

Material |

Steel |

|

Brand |

Jas |

|

Speed |

3500 rpm |

|

Capacity |

280 kg per hr |

|

Power |

7.5 HP |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email