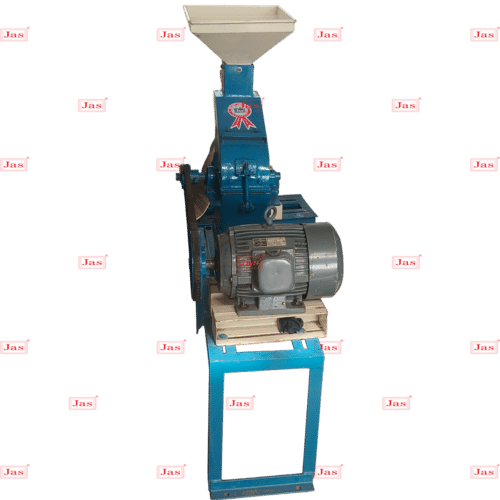

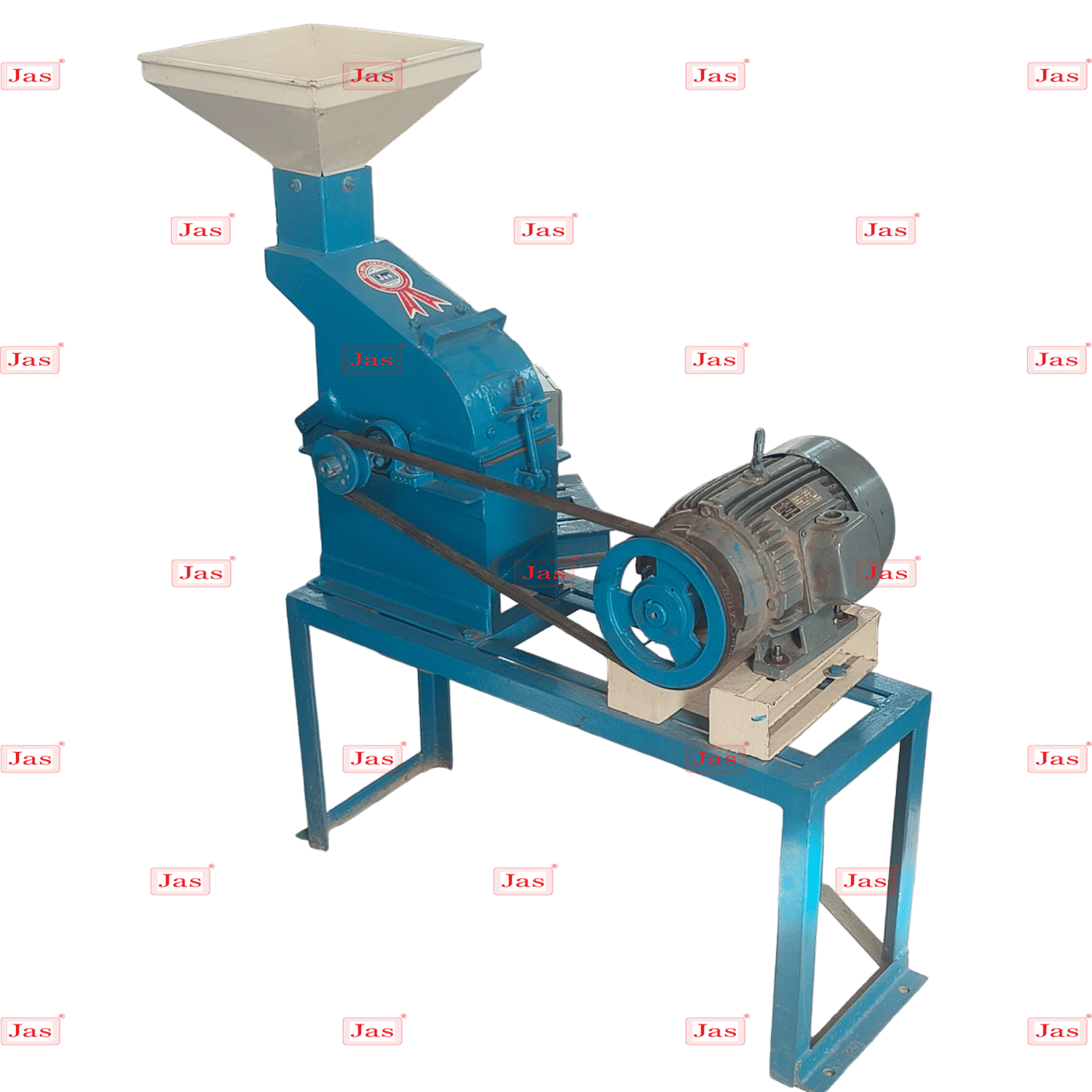

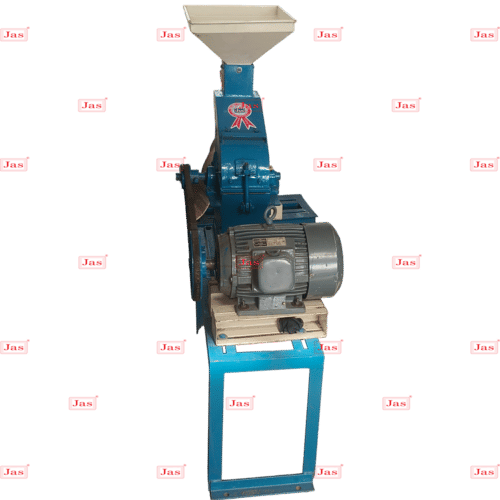

Pulverizer For Mineral Grinding

Product Details:

- Capacity 20-2200 Kg/hr

- Automatic Yes

- Voltage 230/440 Volt (v)

- Feature High Performance ECO Friendly Low Noise Lower Energy Consumption High Efficiency

- Click to View more

Pulverizer For Mineral Grinding Price And Quantity

- 18000.00 - 590000.00 INR/Unit

- 1 Unit

- 18000 INR/Unit

Pulverizer For Mineral Grinding Product Specifications

- Yes

- High Performance ECO Friendly Low Noise Lower Energy Consumption High Efficiency

- 20-2200 Kg/hr

- 230/440 Volt (v)

Pulverizer For Mineral Grinding Trade Information

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque Western Union

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- ISO

Product Description

-

Ball Mills: These are cylindrical devices filled with grinding media (usually steel or ceramic balls) and the material to be ground. The rotation of the cylinder causes the balls to fall and crush the material.

-

Rod Mills: Similar to ball mills but use long rods as grinding media. They are used for coarser grinding than ball mills.

-

Hammer Mills: These use high-speed rotating hammers to crush and grind materials. They are useful for materials that are brittle or less dense.

-

Vertical Roller Mills (VRM): These mills use a combination of compressive and shear forces to grind materials between a rotating table and stationary rollers. They are efficient for grinding very fine materials and have a smaller footprint compared to ball mills.

-

Impact Mills: These include pulverizers that use high-speed impact to break down materials. Examples include jet mills and impact crushers.

-

Attrition Mills: These mills use friction to grind materials. They are often used for very fine grinding and can be used with dry or wet materials.

-

Bead Mills: These use grinding beads suspended in a liquid to grind materials. They are commonly used for very fine and ultra-fine grinding.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+