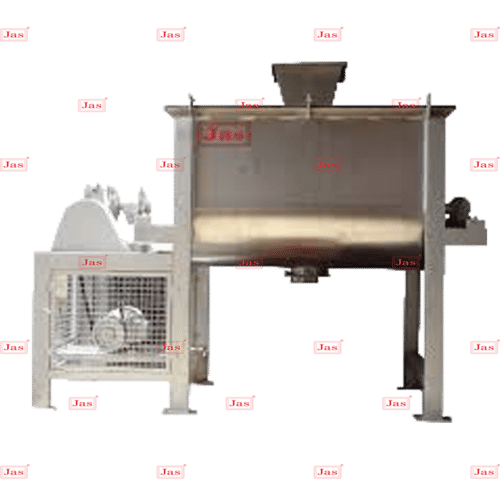

Powder Mixing Ribbon Blender

Price 65000 INR/ Unit

Powder Mixing Ribbon Blender Specification

- Type

- Powder Mixing Ribbon Blender

- Material

- Stainless Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 230-440 Volt (v)

- Frequency (MHz)

- 50-60 Hertz (HZ)

- Size

- Standard / Custom

- Width

- Depends on Model

- Weight

- Approx. 300-1500 Kg (as per model)

- Dimension (L*W*H)

- Customized as per capacity

- Application

- Granules, Powders, Chemicals, Pharmaceuticals, Food

- Motor Power

- 3 HP to 20 HP (varies by model)

- Gearbox Type

- Heavy Duty

- Safety Features

- Overload Protection, Emergency Stop

- Loading Capacity Range

- 50 Kg to 2000 Kg

- Batch Time

- 10-20 minutes

- Mixing Uniformity

- Up to 99%

- Ribbon Design

- Double Helical, Forward and Reverse

- Discharge Outlet

- Manual and Pneumatic

- Finish

- Mirror / Matt Finish available

Powder Mixing Ribbon Blender Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Powder Mixing Ribbon Blender

How It Works:

-

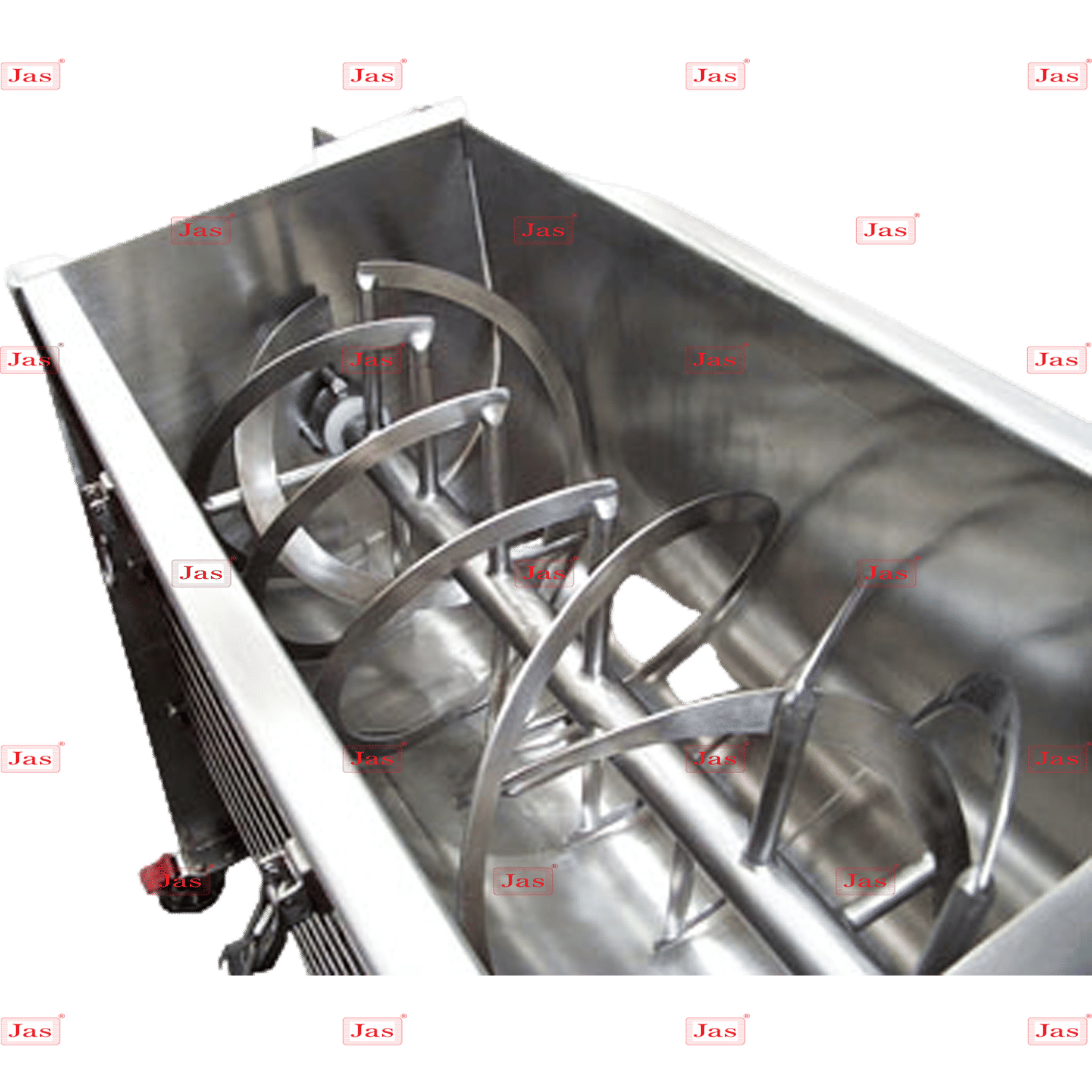

Design: The ribbon blender consists of a horizontal trough with a central shaft equipped with helical ribbons or blades. The ribbons rotate in opposite directions, creating a continuous and efficient mixing action.

-

Mixing Action: As the ribbons turn, they push the material towards the center of the blender, and then back out towards the ends. This movement creates a thorough and consistent blend of powders by repeatedly folding and tumbling the materials.

-

Discharge: Once mixing is complete, the powder can be discharged from the blender through a valve or an opening at the bottom. Some ribbon blenders have a hinged discharge gate for easier cleaning and material removal.

Key Features:

- Capacity: Ribbon blenders come in various sizes, from small laboratory models to large industrial units, depending on the volume of material being processed.

- Material Construction: They are typically made from stainless steel or other durable materials to withstand the abrasive nature of some powders and ensure longevity.

- Customization: Some models can be customized with features such as heating or cooling jackets, spray nozzles for liquid addition, or specialized liners to handle specific materials or improve mixing efficiency.

Efficient Blending for Multiple Industries

Our Powder Mixing Ribbon Blender is engineered for use across pharmaceuticals, food processing, chemicals, and other industries that demand high mixing uniformity. Its double helical ribbon ensures both forward and reverse blending, delivering up to 99% uniformity within short batch cycles. Adaptable discharge outlets and a range of models make it a suitable choice for various production scales and applications.

Robust Construction & Flexible Design

Manufactured from stainless steel with options for mirror or matt finish, this blender is heavy-duty and built to endure rigorous industrial demands. Suitable for batch loads from 50 kg to 2000 kg, its dimensions can be tailored to your production space. The inclusion of overload protection and emergency stop enhances operator safety, while its semi-automatic design ensures ease of use.

FAQs of Powder Mixing Ribbon Blender:

Q: How does the double helical ribbon design improve mixing uniformity in the blender?

A: The double helical ribbon design allows for forward and reverse movement of materials, promoting thorough intermixing throughout the batch. This ensures that powders, granules, or chemicals achieve uniform consistency, reaching mixing uniformity rates of up to 99%.Q: What materials and industries can this Powder Mixing Ribbon Blender be used for?

A: This blender is suitable for blending powders, granules, chemicals, pharmaceuticals, and food ingredients. Its robust stainless steel construction and efficient mixing make it a preferred choice for pharmaceutical, chemical, food processing, and related industries.Q: When should I use manual versus pneumatic discharge outlets?

A: Manual discharge is ideal for applications requiring intermittent or controlled emptying of the mixer, while pneumatic discharge is suitable for faster, automated, or continuous processes. The option allows you to select the most efficient discharge method for your workflow.Q: Where is the Powder Mixing Ribbon Blender produced and supplied?

A: These blenders are manufactured, distributed, exported, and supplied by reputable Indian companies, serving both domestic and international markets through a network of distributors, exporters, retailers, suppliers, traders, and wholesalers.Q: What is the process and batch time for mixing with this ribbon blender?

A: After loading the chosen material into the blending chamber, the double helical ribbons agitate and intermix the batch for about 1020 minutes. Batch size and mixing time depend on the material and model selected.Q: How do the safety features contribute to the operation of the blender?

A: Safety features like overload protection and emergency stop prevent mechanical damage and ensure operator protection during operation, minimizing the risk of accidents or machine downtime.Q: What benefits does this blender offer over other types of mixers?

A: The Powder Mixing Ribbon Blender offers rapid, uniform mixing, high loading capacity, robust stainless steel construction, and versatile discharge options. Its customizable size, multiple safety mechanisms, and adaptability for different materials make it a reliable choice for diverse industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Mixer Blender Category

Heavy Duty Blender

Price 8000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Capacity : 2.520 Ltr/hr

Voltage : 230440 Volt (v)

Frequency (MHz) : 5060 Hz

Ribbon Blenders

Price 65000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Capacity : 100 to 8000 Kg/hr

Voltage : 110/220/380/415 Volt (v)

Frequency (MHz) : 50/60 Hertz (HZ)

Commercial Mixer Blender

Price 8000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Capacity : 2.520 Kg/hr

Voltage : 230440 Volt (v)

Frequency (MHz) : 5060 Hertz (HZ)

Masala Mixing Machine

Price 65000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Capacity : 502000 / 101000 Kg/hr

Voltage : 230440 Volt (v)

Frequency (MHz) : 5060 Hertz (HZ)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS