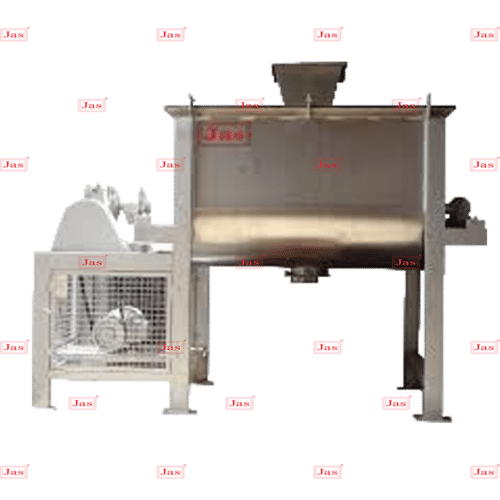

Masala Mixing Machine

Price 65000 INR/ Unit

Masala Mixing Machine Specification

- Material

- Stainless Steel

- Capacity

- 50-2000 / 10-1000 Kg/hr

- Computerized

- No

- Automatic Grade

- Automatic

- Voltage

- 230-440 Volt (v)

- Frequency (MHz)

- 50-60 Hertz (HZ)

- Warranty

- 1 Year

Masala Mixing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Masala Mixing Machine

Types of Masala Mixing Machines:

-

Ribbon Blender: This type has a ribbon-like mixing element that moves in opposite directions to ensure thorough mixing of spices. Its commonly used for dry powders and granules.

-

V-Blender: This machine consists of two cylindrical vessels shaped like a V that rotate to mix the spices. It particularly effective for blending powders with different densities.

-

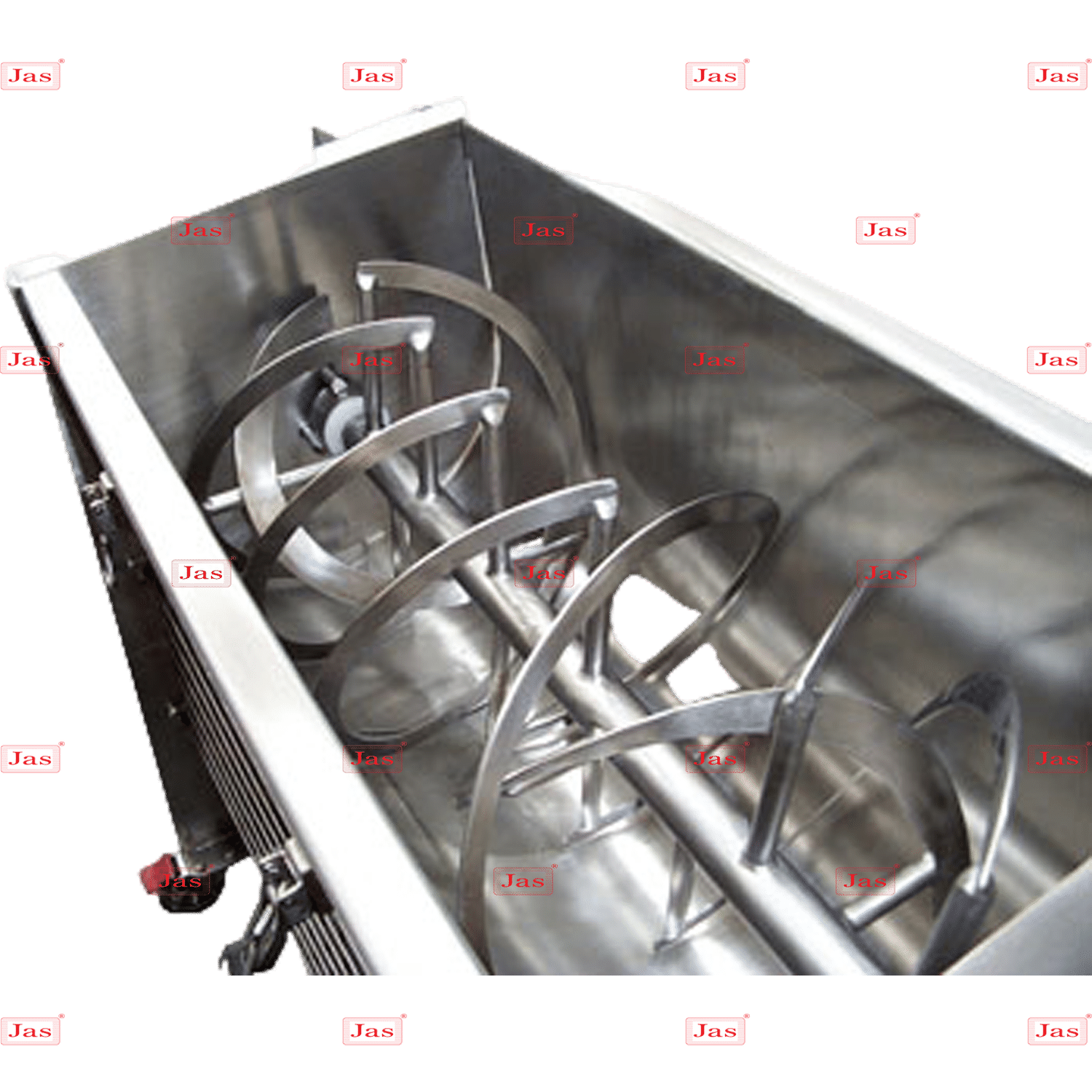

Horizontal Mixer: A horizontal mixer features a horizontal mixing chamber and is used for blending spices on a large scale. It typically includes paddle or ribbon blades.

-

Conical Mixer: With a conical shape, this mixer allows for gentle blending of ingredients. Is useful for mixing spices with various particle sizes.

-

Drum Mixer: This type of mixer uses a rotating drum to blend the spices. Its simple and effective for homogenous mixing in large batches.

Key Features:

-

Capacity: Machines come in various sizes, from small, lab-scale models to large industrial machines capable of handling tons of spices.

-

Material: Typically made from stainless steel to ensure durability and ease of cleaning. Stainless steel also helps prevent contamination.

-

Speed Control: Many machines offer adjustable speed settings to control the mixing process and ensure the desired consistency.

-

Ease of Cleaning: Given the nature of spices, machines are often designed for easy disassembly and cleaning to prevent cross-contamination.

-

Automated Controls: Some advanced models feature programmable controls for precise mixing times and speeds.

Reliable Performance for Industrial Needs

Built from durable stainless steel, the Masala Mixing Machine is engineered to handle continuous operations in commercial and industrial environments. Its automatic functionality streamlines the mixing process, reducing labor and improving output consistency, which is ideal for both small and large spice producers.

User-Friendly Operation

Despite its sophisticated design, the machine is not computerized, making it straightforward and easy to operate. With minimal training, staff can efficiently manage its functions, leading to higher productivity while reducing errors and downtime.

FAQs of Masala Mixing Machine:

Q: How is the Masala Mixing Machine operated?

A: The machine operates automatically without computerized controls, making it easy to use. Operators simply set the required input parameters and the machine handles the mixing process reliably.Q: What materials are used in the construction of this machine?

A: This Masala Mixing Machine is constructed from high-quality stainless steel, ensuring hygiene, resistance to corrosion, and long-term durability in spice production environments.Q: When should I use this machine in my production process?

A: The machine is ideal for use after spices are cleaned and ground, serving the crucial step of mixing before packaging or further processing. It enhances accuracy and blend consistency.Q: Where can the Masala Mixing Machine be sourced in India?

A: You can acquire the machine from a network of distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India, making it widely accessible to diverse businesses.Q: What is the processing capacity of the machine?

A: Depending on the chosen model, the machines capacity ranges from 50-2000 kg or 10-1000 kg per hour, allowing both small and large-scale producers to optimize their spice mixing operations.Q: How does the machine benefit spice manufacturers?

A: By automating the mixing process, this machine guarantees uniform blends, improves operational efficiency, and reduces manual effort, ultimately supporting higher product quality and production volume.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Mixer Blender Category

Heavy Duty Blender

Price 8000 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 5060 Hz

Automatic Grade : SemiAutomatic

Voltage : 230440 Volt (v)

Capacity : 2.520 Ltr/hr

Ribbon Blenders

Price 65000 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50/60 Hertz (HZ)

Automatic Grade : SemiAutomatic

Voltage : 110/220/380/415 Volt (v)

Capacity : 100 to 8000 Kg/hr

Powder Mixing Ribbon Blender

Price 65000 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 5060 Hertz (HZ)

Automatic Grade : SemiAutomatic

Voltage : 230440 Volt (v)

Commercial Mixer Blender

Price 8000 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 5060 Hertz (HZ)

Automatic Grade : Automatic

Voltage : 230440 Volt (v)

Capacity : 2.520 Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS