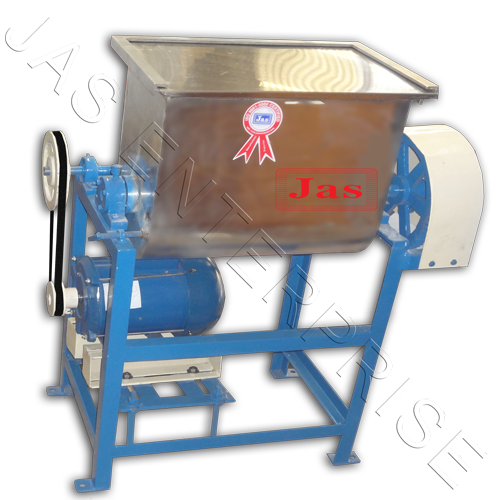

Noodle Flour Mixers

Price 50000 INR/ Piece

MOQ : 1 Piece

Noodle Flour Mixers Specification

- Material

- Stainless Steel

- Capacity

- 10 to 200 Kg/hr

- Automatic

- Yes

- Control System

- PLC Control

- Voltage

- 110-440 Electromagnetic (emu)

- Power

- 2 to 10 Horsepower (HP)

- Feature

- Lower Energy Consumption, ECO Friendly, Low Noice, Compact Structure, High Efficiency

- Warranty

- 1 Year Against Manufacturing Defect At Our Site

Noodle Flour Mixers Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Pieces Per Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Tripura, Meghalaya, Uttarakhand, Daman and Diu, , South India, North India, East India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Manipur, West Bengal, Lakshadweep, Andhra Pradesh, Telangana, Kerala, Central India, Chhattisgarh, Uttar Pradesh, All India

- Certifications

- ISO 9001

About Noodle Flour Mixers

Mixing formula ingredients is often carried out in a horizontal flour mixer for 10-15 minutes. Since the horizontal mixer seems to have better mixing results in commercial noodle production. Mixing results in the formation of a crumbly dough with small and uniform particle sizes. Since the water addition level is relatively low (Vs. bread dough), gluten development in noodle dough during mixing is minimized. This improves the dough sheet ability, sheeted dough smoothness and uniformity.

Limited water absorption also slows down noodle discoloration and reduces the amount of water to be taken out during the final drying or frying processes.

The paddles are positioned to move the material in opposing lateral directions as well as radically. The paddle design is generally employed where friable materials are being blended.

Horizontal Noodle Dough Mixer consists of several elements: a centrally mounted horizontal shaft that rotates within a cylindrical container, paddles, ploughs mixing elements that are attached to the centrally mounted shaft, special openings at the top for feeding materials, manually tilt able tank operated, inside a cylindrical conduit and a complete drive unit.

Innovative Mixing Technology

Featuring a fully automatic PLC control system, these noodle flour mixers optimize your dough preparation processes with high precision and minimal manual intervention. The advanced engineering guarantees consistent, high-quality output with reduced energy usage and minimal operational noise, making them ideal for high-demand environments.

Flexible Capacity for Diverse Needs

With the ability to handle 10 to 200 kg of dough per hour, our mixers suit a variety of production volumes, from boutique operations to large commercial facilities. The stainless steel construction ensures both hygiene and robust, long-lasting performance even with frequent usage.

FAQs of Noodle Flour Mixers:

Q: How does the PLC control system enhance mixer operation?

A: The PLC (Programmable Logic Controller) system automates the mixing process, allowing you to customize timings and speed. This ensures consistent results, reduces manual effort, and minimizes operational errors in both small and large-scale production.Q: What are the benefits of using a stainless steel noodle flour mixer?

A: Stainless steel provides excellent durability, rust resistance, and is easy to clean, making it ideal for food handling applications. It also contributes to hygiene and meets food safety standards, enhancing product quality.Q: When should the mixer undergo maintenance to ensure longevity?

A: Routine maintenance is advised every few months, depending on frequency of use. Regular cleaning and inspections will help prevent wear, especially since the machine is under warranty for one year against manufacturing defects at your site.Q: Where can these noodle flour mixers be installed for optimal performance?

A: These mixers are designed with a compact structure, allowing them to fit into various settings like industrial kitchens, commercial factories, and food production lines across India, ensuring seamless integration into most work environments.Q: What is the usage process for operating these Automatic mixers?

A: Users simply load ingredients, select the desired mixing program via the PLC control panel, and initiate the operation. The mixer does the rest automatically, streamlining dough preparation with minimal manual intervention.Q: How do these mixers support eco-friendly and energy-efficient operations?

A: Our mixers feature lower energy consumption, reducing electrical costs while maintaining high efficiency. Their design promotes sustainability in food production, aligning with modern eco-friendly business practices.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Noodle Processing Machines Category

Noodle Steaming Machines

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Cast Iron

Automatic : Yes

Computerized : No

Capacity : 10 to 100 Kg/hr

Noodle Steamers

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Automatic : Yes

Computerized : Yes

Noodle Dryers

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Automatic : Yes

Computerized : Yes

Capacity : 10 to 200 Kg/hr

Noodle Cutting Machine

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Automatic : Yes

Computerized : No

Capacity : 100 per hurs Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free