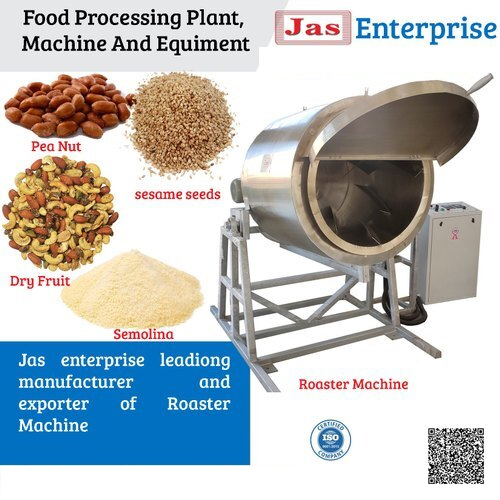

Industrial Flavoring Drum

Product Details:

- Capacity 12-580 Kg/hr

- Automatic Yes

- Voltage 230/440 Volt (v)

- Feature ECO Friendly Lower Energy Consumption High Efficiency

- Click to View more

Industrial Flavoring Drum Price And Quantity

- 45000 INR/Unit

- 45000.00 - 713000.00 INR/Unit

- 1 Unit

Industrial Flavoring Drum Product Specifications

- 230/440 Volt (v)

- ECO Friendly Lower Energy Consumption High Efficiency

- Yes

- 12-580 Kg/hr

Industrial Flavoring Drum Trade Information

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque Western Union

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- ISO

Product Description

-

Drum Structure: The drum itself is usually a large, rotating cylinder made of stainless steel or other food-grade materials. It can vary in size depending on the production capacity required.

-

Flavor Application: Food products, such as snacks (like potato chips or nuts), cereals, or even pet foods, are fed into the drum.

-

Rotation and Mixing: The drum rotates slowly or tumbles the food products inside. This tumbling action ensures even distribution of the flavoring or coating over the entire surface of the products.

-

Flavoring Process: Flavorings or seasonings are added to the drum either through a spray mechanism, powder dispensers, or liquid dispensers. The rotation of the drum helps these flavorings adhere uniformly to the food products.

-

Control Systems: Modern flavoring drums often have sophisticated control systems that regulate the amount of flavoring added, the speed of rotation, and other parameters to achieve consistent quality and flavor distribution.

-

Output: Once the flavoring process is complete, the flavored products exit the drum for further processing or packaging.

-

Cleaning and Maintenance: Regular cleaning and maintenance are crucial to prevent cross-contamination and ensure hygiene standards are met.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+