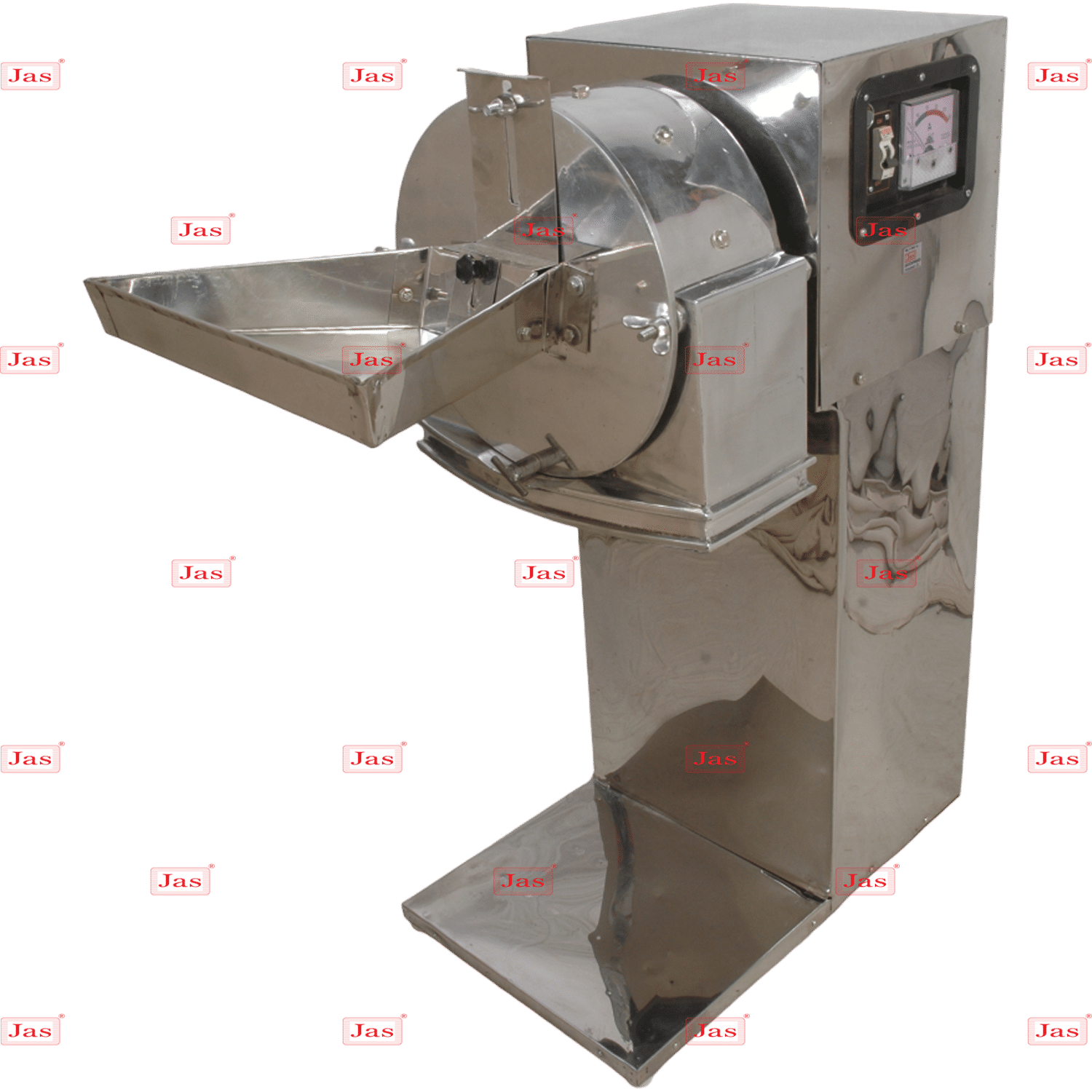

Price 56000 आईएनआर/ Unit

Specification

- क्षमता

- किलो/घंटा

- ऑटोमेटिक

- वोल्टेज

- वोल्ट (v)

- फ़ीचर

- , , , ,

Trade Information

- Minimum Order Quantity

- 1 Unit

- भुगतान की शर्तें

- , , , ,

- मुख्य निर्यात बाजार

- , , , , , , , ,

- मुख्य घरेलू बाज़ार

- , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ,

- प्रमाणपत्र

- ISO

About

-

Cleaning: The harvested turmeric rhizomes are cleaned thoroughly to remove dirt, debris, and any other foreign particles.

-

Boiling or Steaming: Turmeric roots may be boiled or steamed to facilitate easier peeling of the outer skin and to soften the rhizomes.

-

Drying: After boiling or steaming, the turmeric roots are dried to reduce moisture content. This step is crucial for preventing mold growth during storage.

-

Polishing: Dried turmeric roots are polished to improve their appearance by removing any remaining outer skin and making them shiny.

-

Grinding: The polished turmeric roots are ground into a fine powder using industrial grinders. This step is essential to produce the final product that consumers use as a spice.

-

Packaging: Finally, the turmeric powder is packaged into different sizes of bags or containers for distribution and sale in the market.

Precision Engineering and Efficiency

These Turmeric Processing Plants set benchmarks in efficiency, capable of processing between 30 and 160 kilograms per hour while maintaining consistent product quality. Their high-efficiency design minimizes downtime and maximizes throughput, making them a smart investment for businesses seeking reliable food-processing solutions.

Eco-Friendly Innovation

Designed with environmental sustainability in mind, our plants feature energy-saving technologies and low-emission operations. The use of advanced components ensures the plants produce minimal noise and reduce overall energy consumption, aligning with modern eco-friendly manufacturing standards.

FAQs of Turmeric Processing Plants:

Q: How does the automatic operation of this turmeric processing plant benefit my business?

A: The fully automatic operation simplifies workflows, reduces the need for extensive manual intervention, and ensures consistent, high-quality output. This translates to improved productivity, reduced labor costs, and higher efficiency for your processing facility.Q: What makes this turmeric processing plant eco-friendly?

A: The plant is designed with environmental responsibility in mind, incorporating low energy consumption technology and ensuring minimal operational noise. This eco-friendly focus helps your business reduce its carbon footprint while maintaining peak performance.Q: When is the ideal time to choose this plant over manual or semi-automatic alternatives?

A: Opt for this plant when you need scalable, reliable, and efficient processing capabilities. Its automatic features and high capacity are ideal for businesses experiencing growth, aiming to expand, or seeking to modernize their operations for better output and resource management.Q: Where can the turmeric processing plant be installed, and is it suitable for various industrial settings?

A: Thanks to its operational voltage range (230/440 Volt), the plant fits seamlessly into diverse setups across India and beyond. Its compact and robust design is suitable for use in factories, spice mills, and commercial processing units without requiring extensive modifications.Q: What is the turmeric processing procedure in these plants?

A: Turmeric pass through a sequence of automated steps including cleaning, boiling, drying, and grinding. The process ensures hygienic handling, preserves essential nutrients, and produces a uniform, market-ready final product.Q: How does the plant contribute to energy savings and lower operational noise?

A: Integrated with advanced motors and smart energy-management systems, the plant reduces energy usage and emits minimal sound during operation. This dual focus on energy and noise ensures cost-effectiveness and a better working environment.Q: What are the core advantages of sourcing this processing plant from an Indian distributor or manufacturer?

A: Sourcing from a reputable Indian supplier assures robust after-sales service, local technical support, and the benefit of industry experience in spice processing. This leads to trusted partnerships and efficient supply chains for your business.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in हल्दी पीसने की मशीन Category

हल्दी पीसने की मशीन

न्यूनतम आदेश मात्रा : 1

माप की इकाई : टुकड़ा/टुकड़े

मूल्य या मूल्य सीमा : आईएनआर

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें