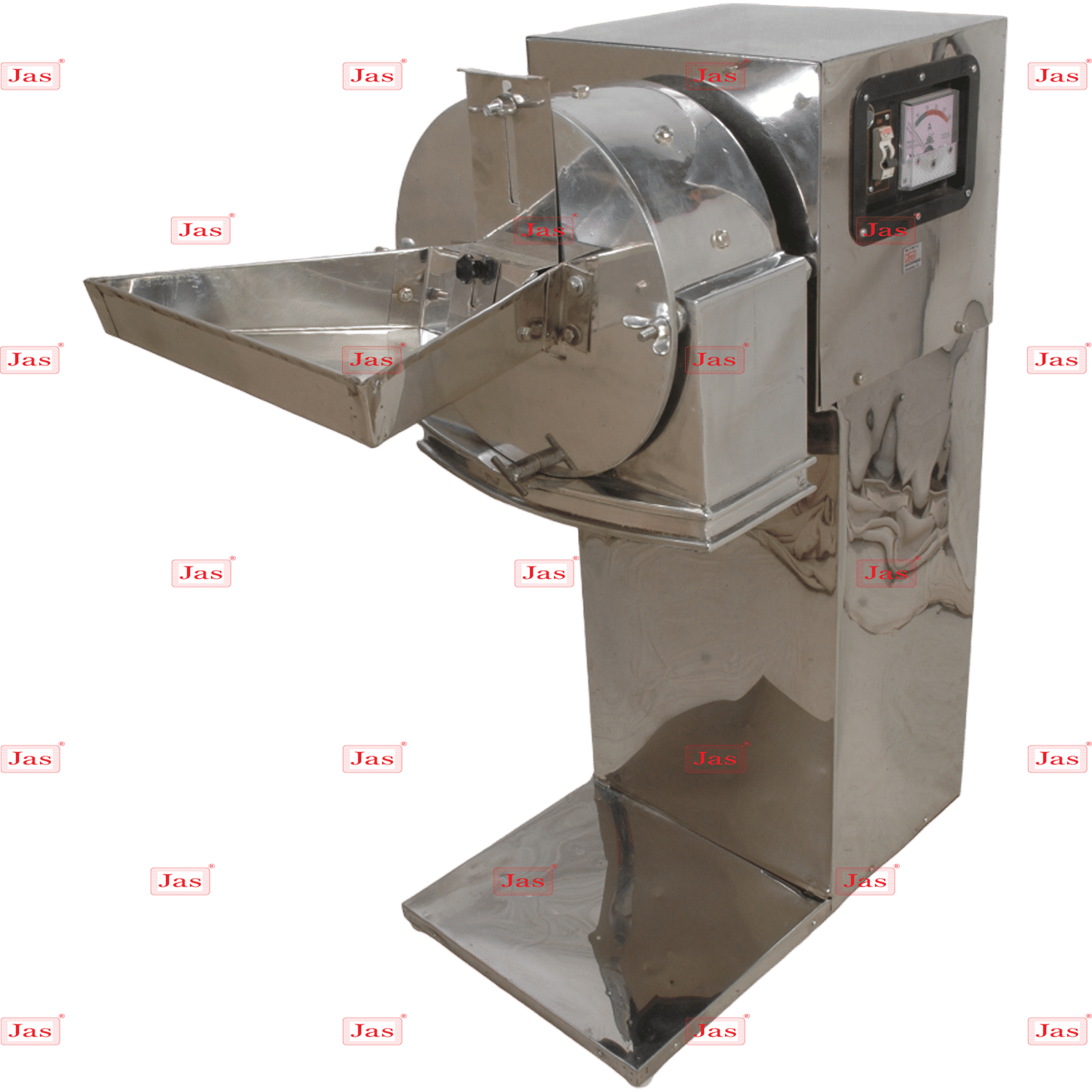

Turmeric Processing Plant

56000 आईएनआर/Unit

उत्पाद विवरण:

- क्षमता किलो/घंटा

- ऑटोमेटिक

- वोल्टेज वोल्ट (v)

- फ़ीचर

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- किलो/घंटा

- वोल्ट (v)

व्यापार सूचना

- ISO

उत्पाद वर्णन

1. Raw Material Procurement

- Selection and Quality Control: High-quality turmeric rhizomes are selected based on factors like color, size, and freshness. Quality control ensures the raw material meets the required standards.

2. Cleaning

- Washing: The turmeric rhizomes are thoroughly washed to remove dirt, soil, and impurities. This can be done using water and sometimes with mild detergents.

3. Boiling or Steaming

- Boiling/Steaming: The cleaned rhizomes are boiled or steamed to soften them, which helps in the drying process and reduces the likelihood of fungal contamination. Steaming is often preferred for better color retention.

4. Drying

- Drying Methods: The boiled or steamed rhizomes are dried using various methods:

- Sun Drying: Traditional method where rhizomes are spread out in the sun.

- Mechanical Drying: Use of dryers or ovens for more controlled and faster drying.

5. Polishing

- Cleaning and Polishing: Dried rhizomes are polished to remove the outer skin and any remaining dirt. This step enhances the appearance and quality of the final product.

6. Grinding

- Milling/Grinding: The dried and polished rhizomes are ground into a fine powder. This powder can be used as turmeric spice or for extraction purposes.

7. Sifting

- Sieving: The ground turmeric is sifted to ensure a uniform particle size and to remove any larger, unwanted particles.

8. Quality Control

- Testing: The turmeric powder undergoes quality control tests for factors such as color, flavor, and purity. Tests may also be conducted for microbial contamination and heavy metal residues.

9. Packaging

- Packaging: The processed turmeric is packaged in moisture-proof and airtight containers to maintain freshness and prevent contamination. Packaging can be done in bulk or retail-sized packages.

10. Storage and Distribution

- Storage: Finished products are stored in a controlled environment to preserve quality.

- Distribution: The packaged turmeric is then distributed to retailers, wholesalers, or directly to consumers.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email