Price 18000 आईएनआर/ Unit

MOQ : 1 Unit

Specification

- क्षमता

- किलो/घंटा

- ऑटोमेटिक

- वोल्टेज

- वोल्ट (v)

- फ़ीचर

- , , , ,

Trade Information

- Minimum Order Quantity

- 1 Unit

- भुगतान की शर्तें

- , , , ,

- मुख्य घरेलू बाज़ार

- , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ,

- प्रमाणपत्र

- ISO

About

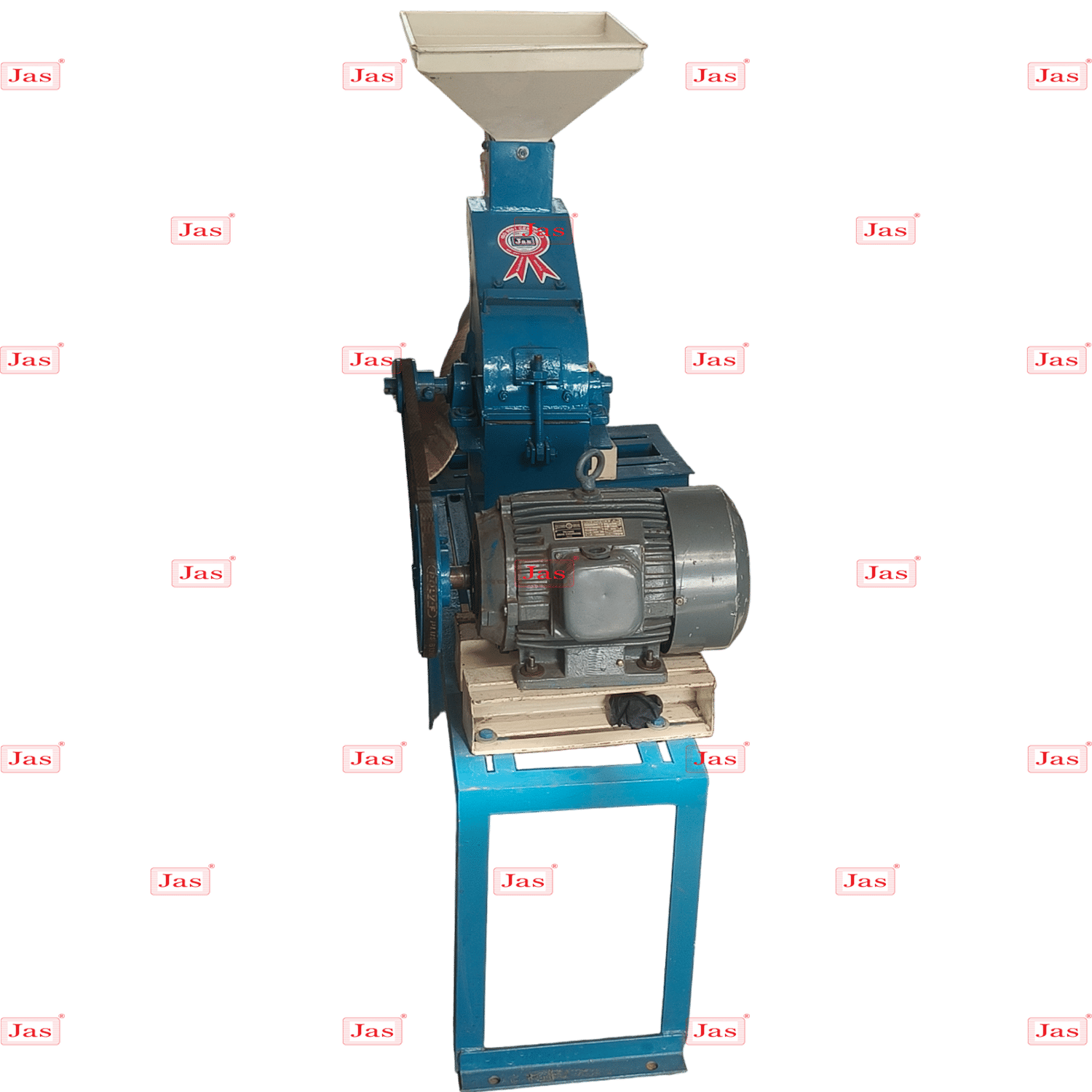

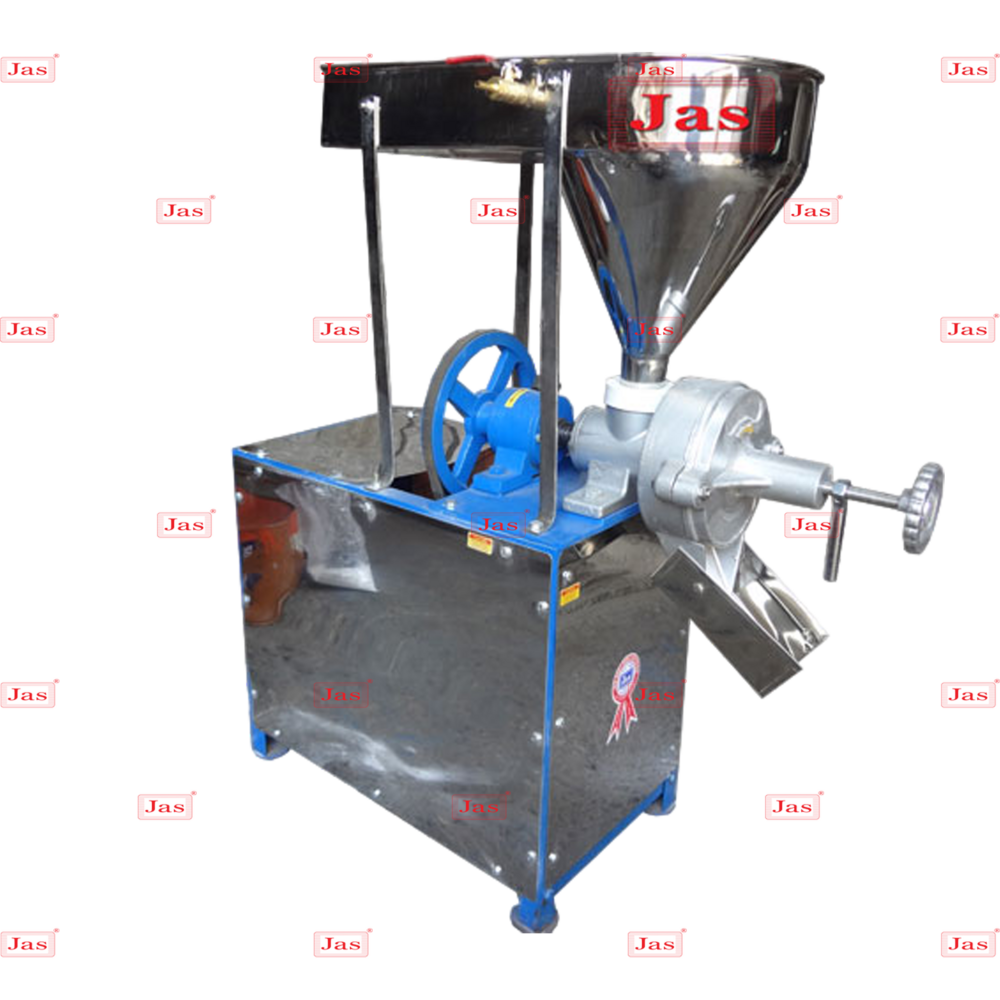

Components:

- Hammer Assembly: This includes a series of heavy hammers or bars that strike the material.

- Rotor: The central shaft to which the hammers are attached, rotating at high speeds.

- Grinding Chamber: The enclosure where the material is fed and ground.

- Screen: Located at the bottom of the chamber, it controls the size of the final product by allowing only particles of a certain size to pass through.

- Inlet and Outlet Ports: For feeding material into the mill and discharging the processed material.

How It Works:

- Feeding: Raw material is fed into the grinding chamber through an inlet.

- Impact and Shearing: As the rotor spins, the hammers strike the material with high force, causing it to break into smaller pieces.

- Screening: The smaller particles that pass through the screen exit the chamber, while larger pieces are repeatedly struck until they are sufficiently small.

- Discharge: The finely ground material is then discharged through an outlet port.

High-Efficiency Grinding Technology

Designed with advanced mechanisms, this hammer mill pulveriser offers maximum material breakdown with high efficiency, enabling faster and more consistent results. Its automatic system further streamlines operations, making it ideal for bulk users in industries that demand high output with minimal energy use.

Eco-Friendly and Low Noise Operations

Utilizing innovative construction, the pulveriser minimizes environmental impact through reduced energy consumption and low operational noise. This makes it suitable for locations where noise pollution and sustainability are important considerations, supporting cleaner and quieter workspaces.

FAQs of Hammer Mill Pulveriser:

Q: How does the automatic Hammer Mill Pulveriser ensure high performance and efficiency?

A: The automatic operation system enables controlled, continuous feeding and grinding, optimizing performance and efficiency across various capacities. Its advanced design also minimizes energy loss and maximizes output per cycle, contributing to high productivity and cost savings.Q: What is the process of installing and operating the Hammer Mill Pulveriser?

A: Installation involves securing the machine on a stable surface and connecting it to a compatible 230/440 Volt power supply. Once set up, operation is straightforwardadjustments can be made for the desired capacity, and the automatic mechanism manages material input and pulverization seamlessly.Q: Where can the Hammer Mill Pulveriser be sourced in India?

A: The pulveriser is available through multiple distribution channels, including authorized distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers throughout India. Customers can source it according to their volume and customization requirements.Q: When should you consider using this type of pulveriser in your operation?

A: This pulveriser suits operations requiring high throughput, energy efficiency, and consistent particle sizes, such as food processing, chemical manufacturing, and waste management. Businesses aiming to scale up production or improve environmental performance benefit significantly from its features.Q: What are the main usage benefits of the Hammer Mill Pulveriser?

A: Key benefits include fast material processing, reduced operational costs due to lower energy consumption, eco-friendly technology, quiet noise profile, and reliability in both small- and large-scale applications. Its versatility allows for processing a broad range of materials safely and efficiently.Q: How does the eco-friendly feature impact operational sustainability?

A: The energy-efficient design cuts electricity usage noticeably, helping businesses lower their carbon footprint. Combined with reduced noise emissions, it fosters a healthier, more sustainable working environment and supports compliance with environmental regulations.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें