Fully Automatic Corn Curls Kurkure Production Line

900000.00 - 2200000.00 INR/Unit

Product Details:

- Material Stainless Steel

- Capacity 100 TO 300 Kg/hr

- Computerized Yes

- Automatic Yes

- Control System PLC Control

- Voltage 440 Volt (v)

- Power 5 to 20 Horsepower (HP)

- Click to View more

X

Fully Automatic Corn Curls Kurkure Production Line Price And Quantity

- 900000.00 - 2200000.00 INR/Unit

- 1 Unit

Fully Automatic Corn Curls Kurkure Production Line Product Specifications

- Stainless Steel

- 5 to 20 Horsepower (HP)

- 440 Volt (v)

- 100 TO 300 Kg/hr

- Yes

- 1 Year Against Manufacturing Defect At Our Site

- Yes

- PLC Control

Fully Automatic Corn Curls Kurkure Production Line Trade Information

- Ahmedabad

- 1000 Unit Per Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Western Europe Asia Australia South America Eastern Europe Middle East Central America North America Africa

- Dadra and Nagar Haveli Pondicherry Uttarakhand Maharashtra South India Central India North India East India West India Andaman and Nicobar Islands Andhra Pradesh Assam Arunachal Pradesh Bihar Chhattisgarh Chandigarh Daman and Diu Goa Haryana Himachal Pradesh Jammu and Kashmir Jharkhand Karnataka Kerala Lakshadweep Madhya Pradesh Mizoram Meghalaya Manipur Nagaland Odisha Punjab Rajasthan Sikkim Tamil Nadu Telangana Tripura West Bengal Delhi Gujarat Uttar Pradesh All India

- ISO 9001

Product Description

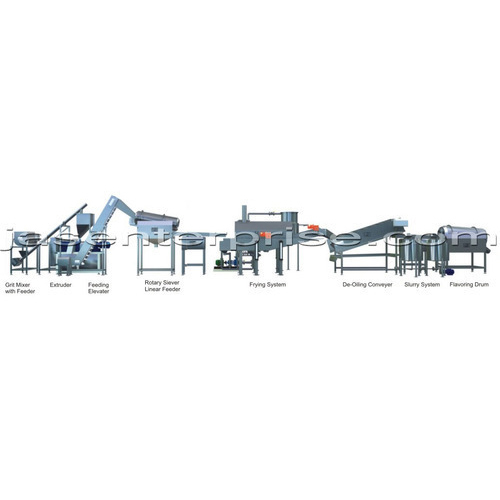

Fully Automatic Corn Curls Kurkure Production Line

Kurkure are extruded snacks, very crunchy and great in taste. Kurkure are made by extrusion process. The kurkure corn meal is moisturized in the flour mixer with water and fed to the rotary die extruder. In the extruder, due to excess heat and pressure from the screws the meal gets heated and the moisture content gets reduced. The meal passes through the die and gets cut by the cutting knifes into required lengths. The kurkure are fried in cooking oil and then cooled before flavoring. Seasoning is sprayed on the kurkure to improve their taste. Machines involved in making kurkure:

- Flour mixer with feeder - to mix corn meal with water to prepare the flour for kurkure and more mixture from mixer machine to rotary head extruder for kurkure type snacks.

- Rotary head extruder for kurkure type snacks - to cook the corn meal and extrude the kurkure from the die. The rotary die twists and curls the meal before extruding giving a uniform texture.

- Feeding elevator - this equipment is proved for transfer the corn curls from extruder to rotary sieve.

- Rotary sieve - the fines or small particles that are produced as the collets are removed by this rotary sieve.

- Continuous frying system with heat exchanger - to fry the kurkure in hot cooking oil. The uniform frying introduces the crunchy taste to the kurkure.

- De-oiling belt to remove exceed oil from corn curls.

- Linear feeder - this devices used to feed corn curls for flavoring on seasoning system.

- Automatic seasoning system with Slurry System - to add required seasoning to the fried and cooled kurkure to give the different flavors to them

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS