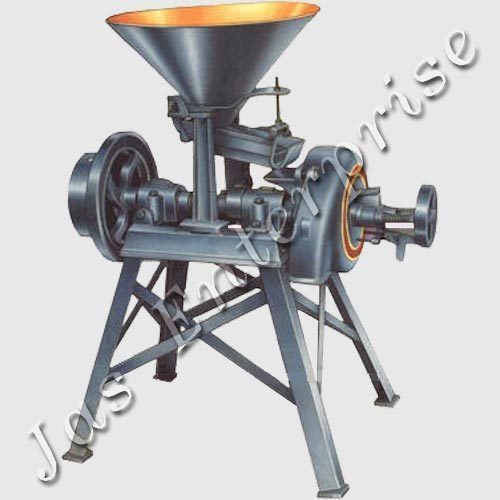

Sugar Grinder

Price 8000.00 INR/ Unit

Sugar Grinder Specification

- Material

- Stainless Steel

- Capacity

- 20 to 2000 Kg/hr

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Installation Type

- Free Stand

- Voltage

- 110-440 Volt (v)

- Feature

- Lower Energy Consumption, ECO Friendly, High Efficiency, Low Noice, Compact Structure

- Warranty

- 1 Year Against Manufacturing Defect At Our Site

Sugar Grinder Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Units Per Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Sikkim, Tripura, Manipur, Meghalaya, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, , South India, Central India, North India, East India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Mizoram, Nagaland, Punjab, Rajasthan, Tamil Nadu, Telangana, West Bengal, Delhi, Gujarat, Maharashtra, Andhra Pradesh, Kerala, Odisha, West India, Chhattisgarh, Uttar Pradesh, All India

- Certifications

- ISO 9001

About Sugar Grinder

Sugar Grinder

Techno wings Fine Sugar Grinders are designed to grind dry, free-flowing sugar as fine as 200 mesh with very tight distribution of particle size. Our grinders highly-efficient design is ideal for heat sensitive materials like sugar, and we have three sizes available to best suit your production needs. Our grinders internals are all easily accessible and maintainable for easy replacement of parts. Techno wings Fine Grinders utilize a high-speed impact principle which allows for precise control of finished particle size and distribution.

Robust and Efficient Grinding Solution

Featuring a capacity range from 20 to 2000 kg/hr, this Sugar Grinder is perfect for both small-scale and large-scale operations. Its computerized PLC control ensures precise and automated performance, enhancing productivity while reducing manual intervention. The energy-saving features and compact structure add further value for diverse clientele.

Sustainable Design and Easy Installation

Built from high-grade stainless steel, the grinder promises long-lasting durability and hygiene. Its eco-friendly attributes and lower energy consumption make it a responsible choice. The free-standing installation type allows for seamless placement and relocation within your facility, providing flexibility for various operational layouts.

FAQs of Sugar Grinder:

Q: How does the computerized PLC control system benefit the sugar grinding process?

A: The PLC (Programmable Logic Controller) system streamlines operation, enabling precise automatic control over the grinding speed, consistency, and overall process. This reduces the need for manual adjustments, ensures uniform quality, and maximizes operational efficiency.Q: What materials are used in the construction of this sugar grinder?

A: This sugar grinder is manufactured from high-quality stainless steel, which not only enhances durability but also ensures food-grade safety standards and easy cleaning, ideal for both industrial and commercial environments.Q: When should the grinder be serviced or maintained?

A: Regular inspections and maintenance are recommended to ensure optimal performance. As per the warranty and manufacturers guidelines, routine checks every 6 to 12 months are ideal, with immediate attention required if unusual noise or reduced efficiency is noticed.Q: Where can this sugar grinder be installed?

A: Thanks to its compact, free-standing design, the grinder can be conveniently installed in a variety of environments, including factories, commercial kitchens, or production floors. It does not require wall mounting or complex installation processes.Q: What is the process for operating the automatic sugar grinder?

A: Operation involves feeding sugar into the hopper, setting the desired parameters through the touch-based PLC control panel, and starting the machine. The grinder will automatically process the sugar while maintaining consistent output based on the programmed settings.Q: What are the primary benefits of using this sugar grinder compared to conventional models?

A: Key advantages include lower energy consumption, reduced operating noise, higher efficiency, automated controls for consistent quality, and a space-saving design. Its eco-friendly operation and robust warranty make it a practical investment for various businesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Pulverizers Category

Stoneless Atta Chakki

Price Range 25000.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year Against Manufacturing Defect At Our Site

Automatic : Yes

Capacity : 30 to 170 Kg/hr

Instant Wet Rice Grinder Machine

Price Range 15000.00 - 50000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year Against Manufacturing Defect At Our Site

Automatic : Yes

Capacity : 30 to 100 Kg/hr

Plate Type Grinding Mills

Price Range 15000.00 - 50000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year Against Manufacturing Defect At Our Site

Automatic : Yes

Capacity : 30 to 100 Kg/hr

Coconut Pulverisers

Price 190000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS