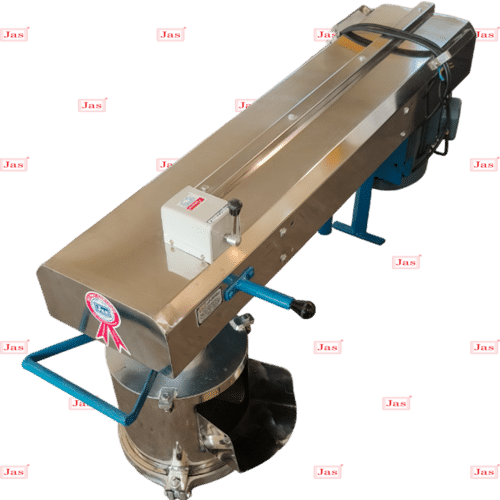

Snacks Processing Machine

Product Details:

- Capacity 25-200 Kg/hr

- Automatic Yes

- Voltage 230/440 Volt (v)

- Feature ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- Click to View more

Snacks Processing Machine Price And Quantity

- 1 Unit

- 25000.00 - 102000.00 INR/Unit

- 25000 INR/Unit

Snacks Processing Machine Product Specifications

- Yes

- 230/440 Volt (v)

- ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- 25-200 Kg/hr

Snacks Processing Machine Trade Information

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque Western Union

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- ISO

Product Description

Here™s a general overview of how a typical snacks processing machine might work:

-

Ingredient Mixing: Some machines can mix different ingredients according to specific recipes. This might include seasoning, flavorings, and other additives.

-

Cooking or Baking: Depending on the type of snack, the machine might cook or bake the ingredients. For example, for potato chips, the machine might fry the sliced potatoes in oil.

-

Drying: For snacks that require drying, such as dried fruit or beef jerky, machines can provide controlled heat and airflow to remove moisture.

-

Flavoring: After cooking, snacks often need to be coated with flavorings or seasonings. Machines equipped with tumblers or sprayers can evenly apply these coatings.

-

Cooling: Some machines include a cooling section to bring down the temperature of hot snacks to make them crisp and ready for packaging.

-

Packaging: Finally, the processed snacks are usually packaged automatically. This might involve filling bags, sealing them, and labeling them.

The specific features and capabilities of snacks processing machines can vary widely depending on the type of snack being produced and the scale of production. For example, a machine for large-scale industrial use will differ from one designed for small-batch artisanal production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+