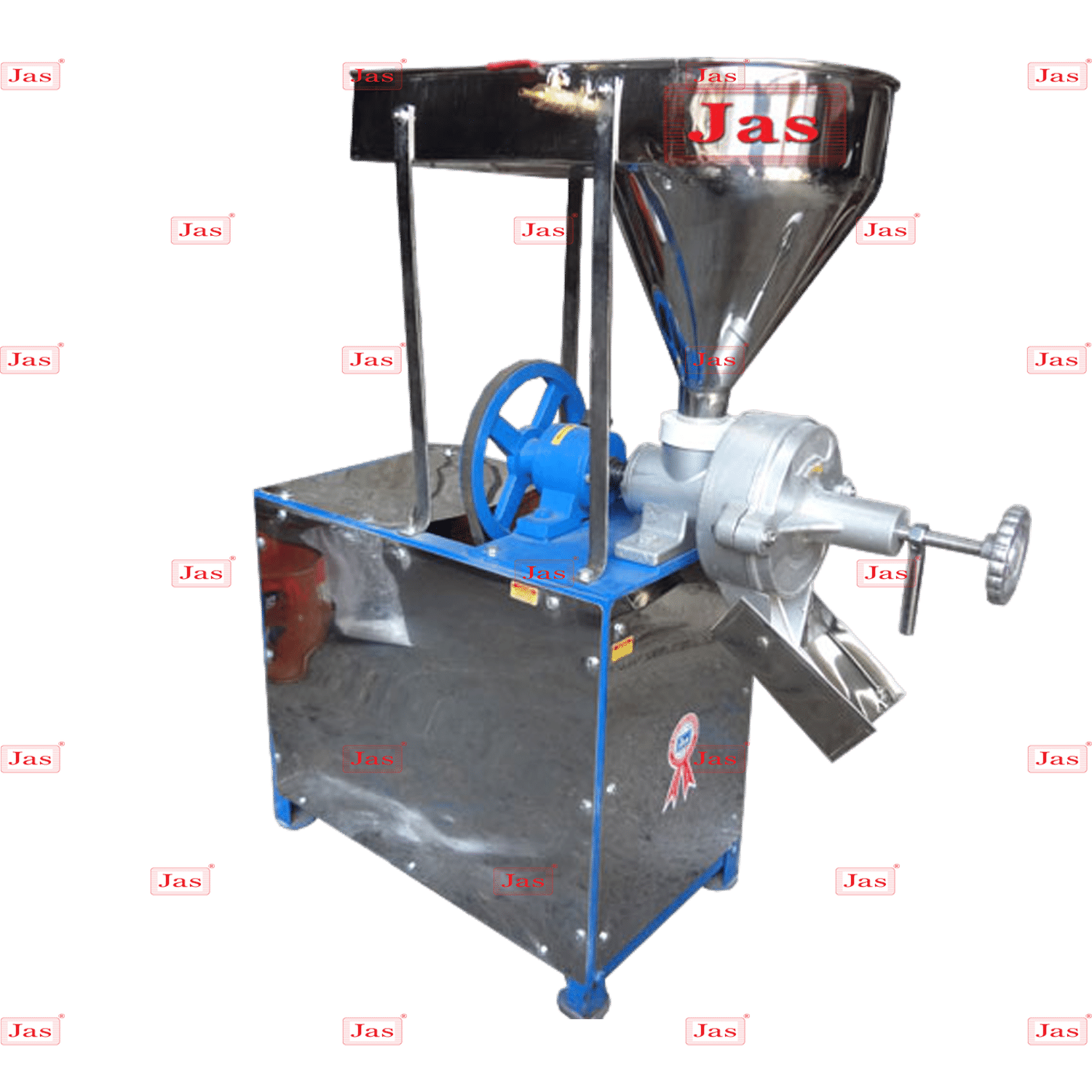

Rice Flour Grinding Machine

Price 24000 INR/ Unit

Rice Flour Grinding Machine Specification

- Power Source

- Electric

- General Use

- Industrial

- Material

- Stainless Steel

- Capacity

- 30-250 Kg/hr

- Automatic

- Yes

- Control System

- PLC Control

- Installation Type

- Free Stand

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Color

- Sliver

- Warranty

- 1 Year

Rice Flour Grinding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Rice Flour Grinding Machine

Key components of a typical rice flour grinding machine may include:

- Hopper: Where raw rice grains are fed into the machine.

- Grinding Mechanism: This usually consists of rotating abrasive discs or stones that crush the rice grains into fine flour.

- Motor: Provides the power necessary to drive the grinding mechanism.

- Adjustable Settings: Some machines allow adjustment of the coarseness or fineness of the flour produced.

- Collection Container: Where the ground rice flour is collected after grinding.

These machines are designed to efficiently process rice grains into flour, ensuring consistent quality and texture. They are used in various food industries, bakeries, and even in home kitchens where finely ground rice flour is needed for cooking or baking purposes.

Superior Automation and Control

Equipped with an intuitive PLC control system, this rice flour grinding machine streamlines the entire production process, ensuring consistent, high-quality output. Operators enjoy simple management and monitoring capabilities, allowing for precise adjustments and minimal downtime. The systems automated features contribute to overall productivity.

Energy-Efficient Design

Engineered for lower energy consumption and minimal noise, the machine not only reduces operational costs but also fosters a more sustainable manufacturing environment. Its compact structure enables flexible placement within diverse industrial settings, making it a space-efficient solution for businesses seeking environmental responsibility and cost management.

High-Capacity Performance

Capable of handling 30 to 250 kg of rice per hour, the rice flour grinding machine accommodates both small-scale and large-scale operations. Consistent high efficiency guarantees robust productivity, while the stainless steel construction ensures hygiene and durability across repeated, intensive industrial use.

FAQs of Rice Flour Grinding Machine:

Q: How does the PLC control system enhance the operation of the rice flour grinding machine?

A: The PLC control system automates various aspects of the grinding process, delivering precise control, consistent performance, and easy monitoring. This helps reduce manual intervention, improve safety, and streamline production workflows.Q: What is the typical installation process for this free-standing rice flour grinding machine?

A: Installation is straightforward for this machine since it is designed as a free-standing unit. After placing the machine at the desired location, connect the electrical supply as per the voltage requirements, and then configure the PLC system for immediate operation.Q: When should I perform maintenance on the rice flour grinding machine?

A: Regular cleaning and inspection should be performed weekly to maintain optimal efficiency. Scheduled maintenance checks are recommended every few months, and the 1-year warranty provides support for unexpected repairs during the initial period of operation.Q: Where can this grinding machine be utilized within industrial setups?

A: It is suitable for use in food processing plants, rice mills, commercial kitchens, and any industrial facility focused on bulk rice flour production. Its compact footprint allows flexible placement even in space-restricted environments.Q: What is the process for grinding rice using this machine?

A: The process involves feeding cleaned rice into the hopper, where it is then automatically ground into flour via internal mechanisms controlled by the PLC system. The output flour is collected for further processing or packaging.Q: How does using this machine benefit industrial operations?

A: Users benefit from high efficiency, reduced energy consumption, lower operational noise, and increased hygiene thanks to its stainless steel build. The machines automation ensures consistent quality and higher throughput, which can significantly increase productivity and profitability.Q: What are the available support options for distributors and retailers in India?

A: Distributors, retailers, and other partners in India have access to dedicated support services, including installation assistance, technical guidance, product training, and warranty coverage for one year, ensuring seamless operation and long-term reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Pulverizers Category

Stainless steel Pulverizer

Price 16500 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Control System : Manual

Capacity : 2050 kg/hr

Jacketed Mini Pulverizers

Price Range 25000.00 - 55000.00 INR / Unit

Minimum Order Quantity : 1 Ohm

Warranty : 1 Year Against Manufacturing Defect At Our Site

Control System : Manual

Capacity : 10 to 100 Kg/hr

Sugar Grinder

Price 8000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year Against Manufacturing Defect At Our Site

Control System : PLC Control

Capacity : 20 to 2000 Kg/hr

Plate Type Grinding Mills

Price Range 15000.00 - 50000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year Against Manufacturing Defect At Our Site

Control System : Manual

Capacity : 30 to 100 Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS