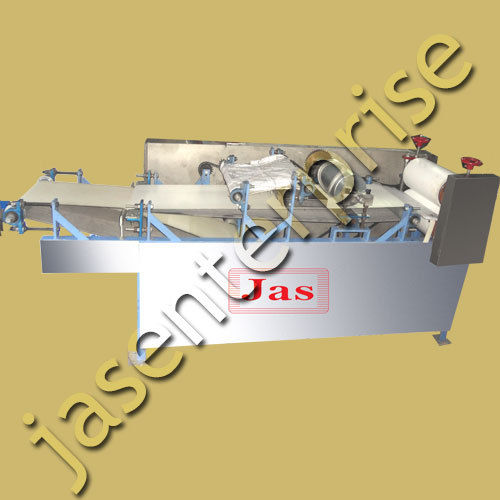

Raw Chapati Making Machines

Product Details:

- Material Stainless Steel

- Type Roti Making Machine

- Capacity 600 to 3000 Chapati/Hr Pcs/min

- Product Shape Round

- Computerized Yes

- Automatic Yes

- PLC Control Yes

- Click to View more

Raw Chapati Making Machines Price And Quantity

- 10000.00 INR/Unit

- 1 Unit

Raw Chapati Making Machines Product Specifications

- 600 to 3000 Chapati/Hr Pcs/min

- Roti Making Machine

- Round

- Stainless Steel

- High Quality Non Stick Coating Environment Friendly Low Noise High Efficiency Multi Functional

- Yes

- Yes

- Gas

- Yes

- 110 - 440 Volt (v)

Raw Chapati Making Machines Trade Information

- Ahmedabad

- 1000 Unit Per Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Australia North America Eastern Europe Western Europe Central America Middle East South America Asia Africa

- Himachal Pradesh Andaman and Nicobar Islands Nagaland Uttarakhand Daman and Diu Dadra and Nagar Haveli Lakshadweep South India East India West India Assam Arunachal Pradesh Bihar Chandigarh Delhi Gujarat Goa Jammu and Kashmir Jharkhand Maharashtra Mizoram Meghalaya Manipur Punjab Pondicherry Sikkim Tamil Nadu Telangana Tripura Uttar Pradesh West Bengal Haryana Madhya Pradesh Rajasthan Karnataka North India Andhra Pradesh Kerala Central India Odisha Chhattisgarh All India

- ISO 9001

Product Description

Raw Chapati Making Machines

Automatic raw chapatti & puri making machine dough just needs to be fed into the hopper and at the outlet one gets raw chapati or puri. Apart from this no oil is required. Thus, these machines offer oil free, hygienic Chapatis at economical prices. This raw chapatti & puri making machine is presented with suitable silicon controlled rectifier rated direct current motor with base speed 300 to 3000 RPM electric motor with variable speed direct current drive which converts incoming single-phase alternating current volts to direct current volts. During this conversion process, DC drive regulates speed, torque, voltage and current conditions of the DC motor. One set of TEFLON coated roll with thickness setting arrangement, flour sprinkling arrangement, and one number dies roll, endless PVC food grade belt is mounted on stainless steel covered fabricated angle stand. This machine is able to produce 1000 to 1200 Chapatis per hour or 1500 to 1800 puri per hour depends on the diameter of chapati and puri and required little space 98 inches length x 24 inches width x 43 inches height.

Operating System of Raw chapati Maker:-

Dough Mixer (Dough Kneading Machine):

This machine would consist of heavy-duty stainless steel body with multi-purpose arms. Heavy-duty gears are providing to take the full load and to avoid damage to the mixer arms. (Please note that this dough kneading machine is not standard part of raw chapati making machine)

Dough Sheeter:

Dough sheeting machine consisting of a heavy- duty frame with gauging rollers driven by a motor with gearbox arrangement would be provided. The horizontal hopper would be of Stainless steel with proper taper. The dough is smooth formed from the hopper in the form of a sheet and feed to the gauging rollers. The distance between the gauging rollers would be adjustable and this would depend on the desired thickness of the roti, chapati or puri. The rollers would be TEFLON coated (food-grade material). There would be an intermediate conveyor to feed the dough sheet to the rotary cutting unit. The conveyor belt would be of food-grade material.

Rotary Cutting Unit:

A rotary cutting is would be fitted on a roller for smooth and accurate cutting Roti, chapatti as per the desired size. There would be a provision for shifting the generated Chapatti scrap back to the scrap collection tray.

Standard accessories of Raw chapati making machine: -

- 1 horsepower Silicon Controlled Rectifier rated D.C. motor with base speed 300 to 3000 Rpm electric motor along with variable speed DC drive which converts incoming three or single-phase AC volts to DC volts. During this conversion process DC drives then can regulate speed, torque, voltage and current conditions of the DC motor.

- One number of die roll

- Extra accessories of raw chapati making machine:-

- Dough Kneader

- Extra die roll if required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+