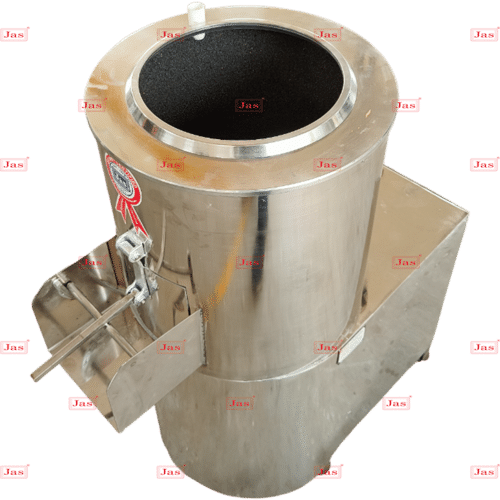

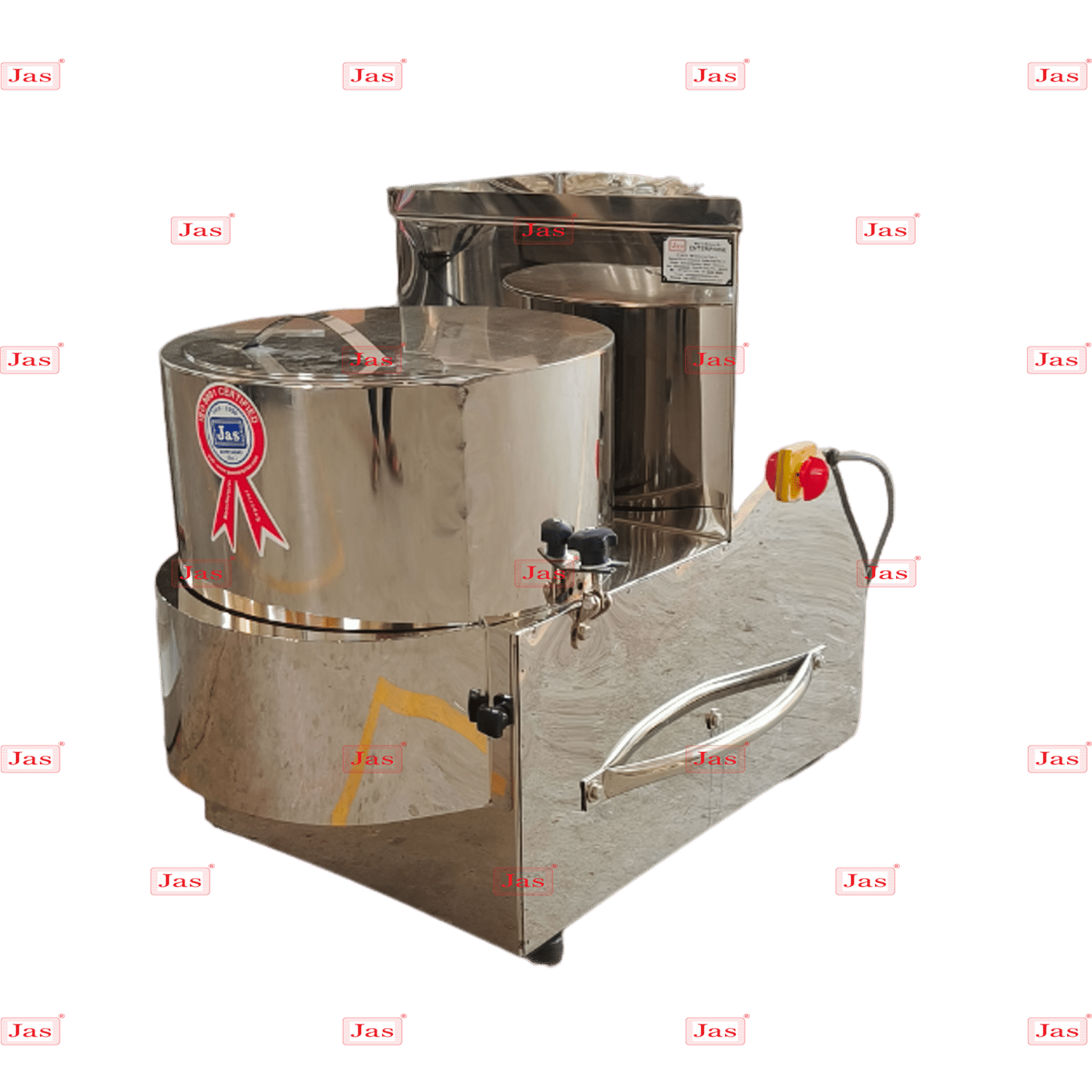

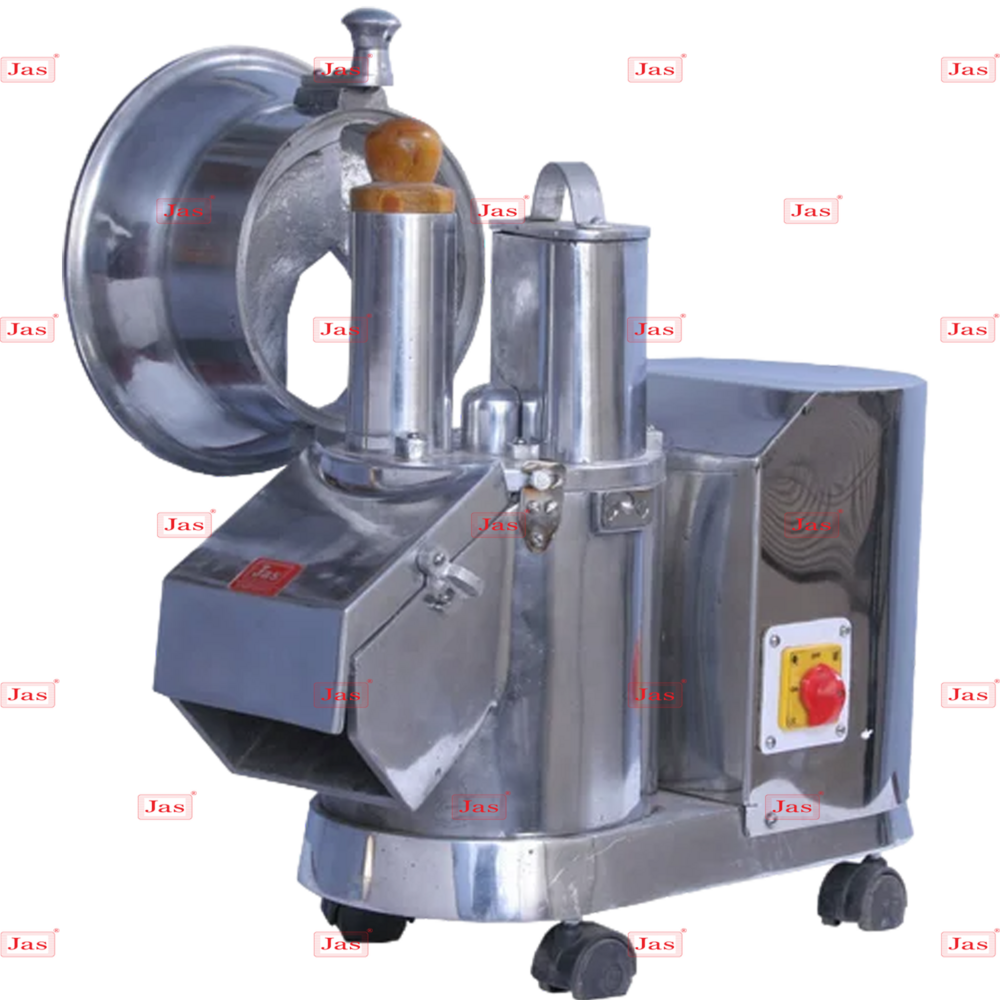

Potato Peeling & Slicing Machine

Price 17000 INR/ Unit

Potato Peeling & Slicing Machine Specification

- Capacity

- 5-50 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Potato Peeling & Slicing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Potato Peeling & Slicing Machine

Types of Potato Peeling & Slicing Machines

-

Manual Machines: These are generally smaller, less expensive, and suitable for home use or small-scale operations. They require manual cranking or turning to peel and slice potatoes.

-

Electric Machines: These are more automated and suitable for commercial use. They can peel, slice, and sometimes even dice potatoes with little effort. Theyre ideal for restaurants or food processing facilities.

-

Combination Machines: Some machines combine peeling, slicing, and sometimes even cooking functions. These are convenient for large-scale operations.

Key Features to Look For

-

Capacity: Choose a machine with a capacity that fits your needs, whether its for a single household or a large commercial kitchen.

-

Peeling Mechanism: Different machines use various peeling mechanisms, such as abrasive peeling, rotary peeling, or chemical peeling. Each has its own advantages depending on the level of efficiency and the texture of the final product you want.

-

Slicing Options: Look for machines that offer different slicing options and thickness settings. This allows you to customize the slices for different recipes or presentations.

-

Ease of Cleaning: Machines that are easy to disassemble and clean will save time and reduce the risk of contamination.

-

Durability: Commercial-grade machines should be made from high-quality materials like stainless steel to ensure they can handle frequent use and tough conditions.

-

Safety Features: Ensure the machine has safety features such as guards or emergency shut-offs to prevent accidents.

-

Size and Storage: Consider the size of the machine in relation to your workspace. Some machines are bulky and may require dedicated storage space.

High-Efficiency Food Preparation

This potato peeling and slicing machine streamlines bulk vegetable preparation for commercial kitchens, catering businesses, and food production facilities. Its automated functions minimize manual labor, deliver consistent results, and help maintain peak hygiene standards. With capacity options ranging from 5 to 50 kg/hr, it can accommodate both small-scale and large-scale operations.

Eco-Friendly and Cost-Saving Operation

Equipped with energy-efficient components and low noise technology, this machine promotes a cleaner and quieter workspace. The design helps businesses reduce electricity consumption, contributing to lower operational costs. Its compact build ensures it fits easily within limited spaces, making it a versatile choice for modern food industry settings.

FAQs of Potato Peeling & Slicing Machine:

Q: How does the potato peeling and slicing machine operate?

A: This machine uses automatic controls to efficiently peel and slice potatoes. Simply load unpeeled potatoes into the chamber, select the desired settings, and the machine will process them with minimal supervision, delivering uniform slices ready for further processing.Q: What are the power requirements for this machine?

A: The machine can be operated on standard 230 or 440 volt (v) electrical supplies, allowing flexibility for various industrial and commercial setups.Q: When is it ideal to use this machine in food processing?

A: It is best used during high-volume preparation tasks, particularly when consistent peeling and slicing are required. It is suitable for food businesses that need efficiency and uniformity in their vegetable preparation processes.Q: Where can this machine be installed?

A: Thanks to its compact structure, the machine can be installed in commercial kitchens, food processing plants, and catering units with limited floor space, as well as larger industrial environments across India.Q: What is the process for operating and maintaining this device?

A: To use the machine, load potatoes and select the desired operation mode. Regular cleaning and basic checks for blade sharpness and motor functionality are advised for optimal performance and product longevity.Q: What are the main benefits of using this machine?

A: Key benefits include reduced labor effort, faster processing times, energy savings, eco-friendly operation, low noise levels, and efficient use of workspace, all contributing to improved productivity and sustainability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Idli Steamer Gas

Price 15000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Capacity : 24120 Idlis per batch (varies with model)

Automatic : Yes

Feature : Other, Rust Proof, Durable Construction, Energy Efficient

Automatic Coconut Flakes Machine

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 230/440 Volt (v)

Capacity : 1001000 Kg/hr

Automatic : No

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Fruit Crusher

Price 9000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Capacity : 500 Kg per hr Kg/hr

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free