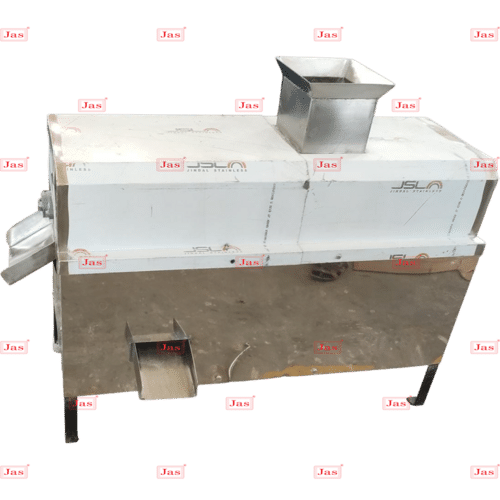

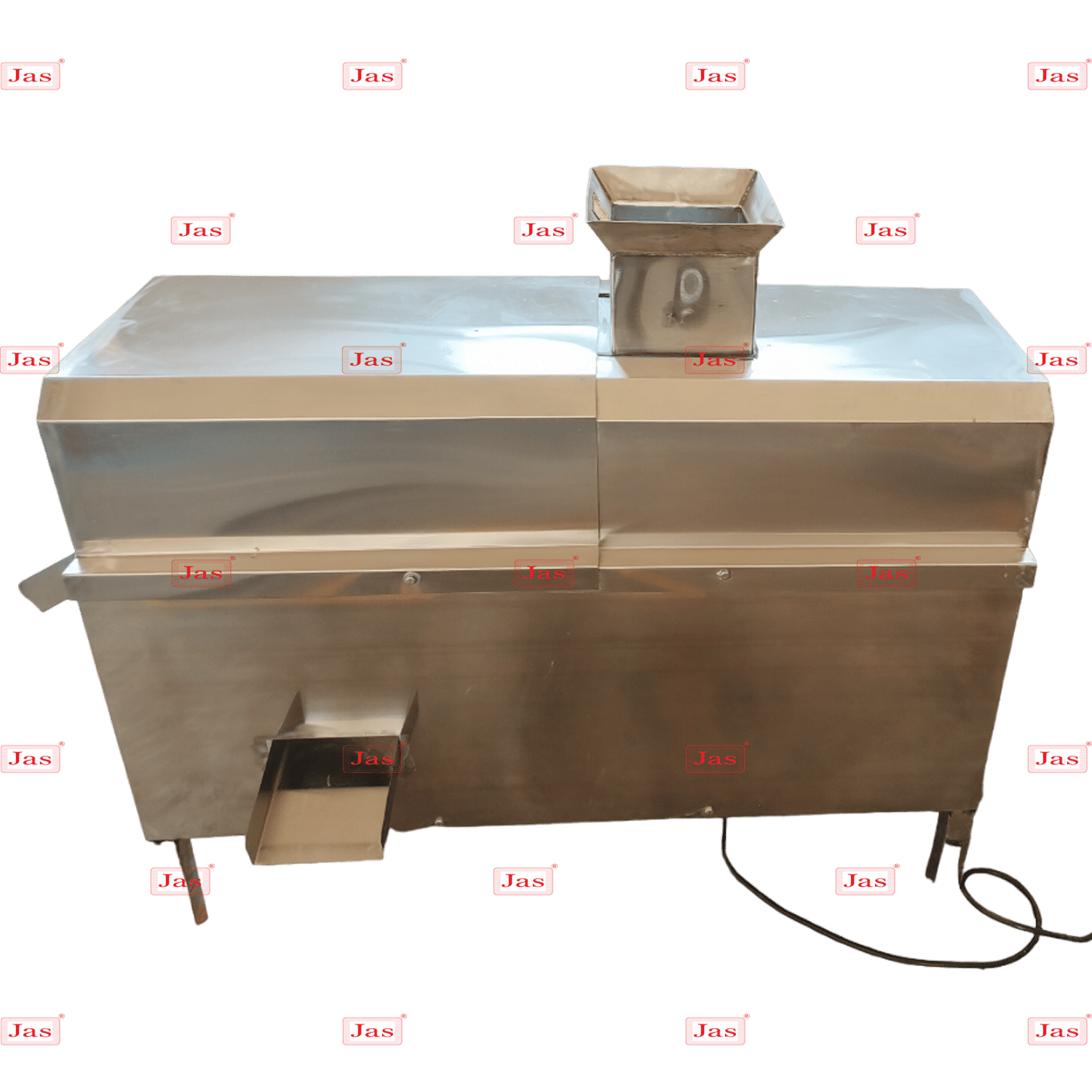

Mango Pulp Machine

33000 INR/Unit

Product Details:

- Voltage 230-440 Volt (v)

- Frequency (MHz) 50-60 Hertz (HZ)

- Click to View more

X

Mango Pulp Machine Price And Quantity

- 33000 INR/Unit

- 1 Unit

- 33000.00 - 350000.00 INR/Unit

Mango Pulp Machine Product Specifications

- 230-440 Volt (v)

- 50-60 Hertz (HZ)

Mango Pulp Machine Trade Information

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque Western Union

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

Product Description

How It Works:

- Feeding: Mangoes are fed into the machine. Some models require pre-cut or peeled mangoes, while others can handle whole fruits.

- Processing: The machine typically uses a combination of crushing, pressing, and sieving to separate the pulp from the skin and seed.

- Collection: The extracted pulp is collected in a separate container, while the waste (skin and seed) is expelled.

- Capacity: Machines vary in size and capacity. Choose one based on your production needs”whether it's for a small scale or large commercial use.

- Material: Look for machines made from food-grade stainless steel for durability and hygiene.

- Ease of Cleaning: The machine should be easy to disassemble and clean to maintain food safety standards.

- Efficiency: Consider the speed and efficiency of pulp extraction. Some machines have features to reduce waste and maximize yield.

- Power Requirements: Check the power requirements and ensure you have the necessary electrical setup.

- Manual Machines: Operated by hand, suitable for small-scale or occasional use.

- Electric Machines: Powered by electricity, ideal for larger quantities and continuous processing.

- Industrial Machines: High-capacity, designed for large-scale production in factories or commercial settings.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email