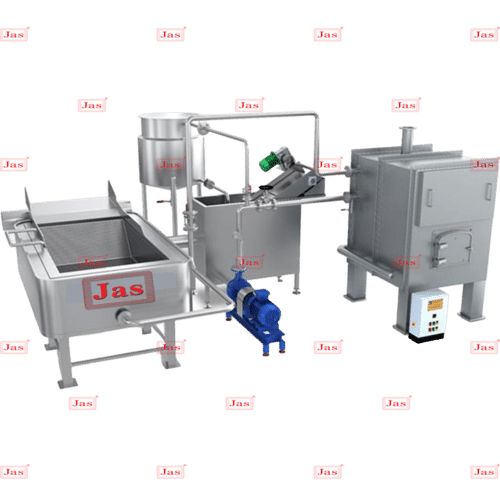

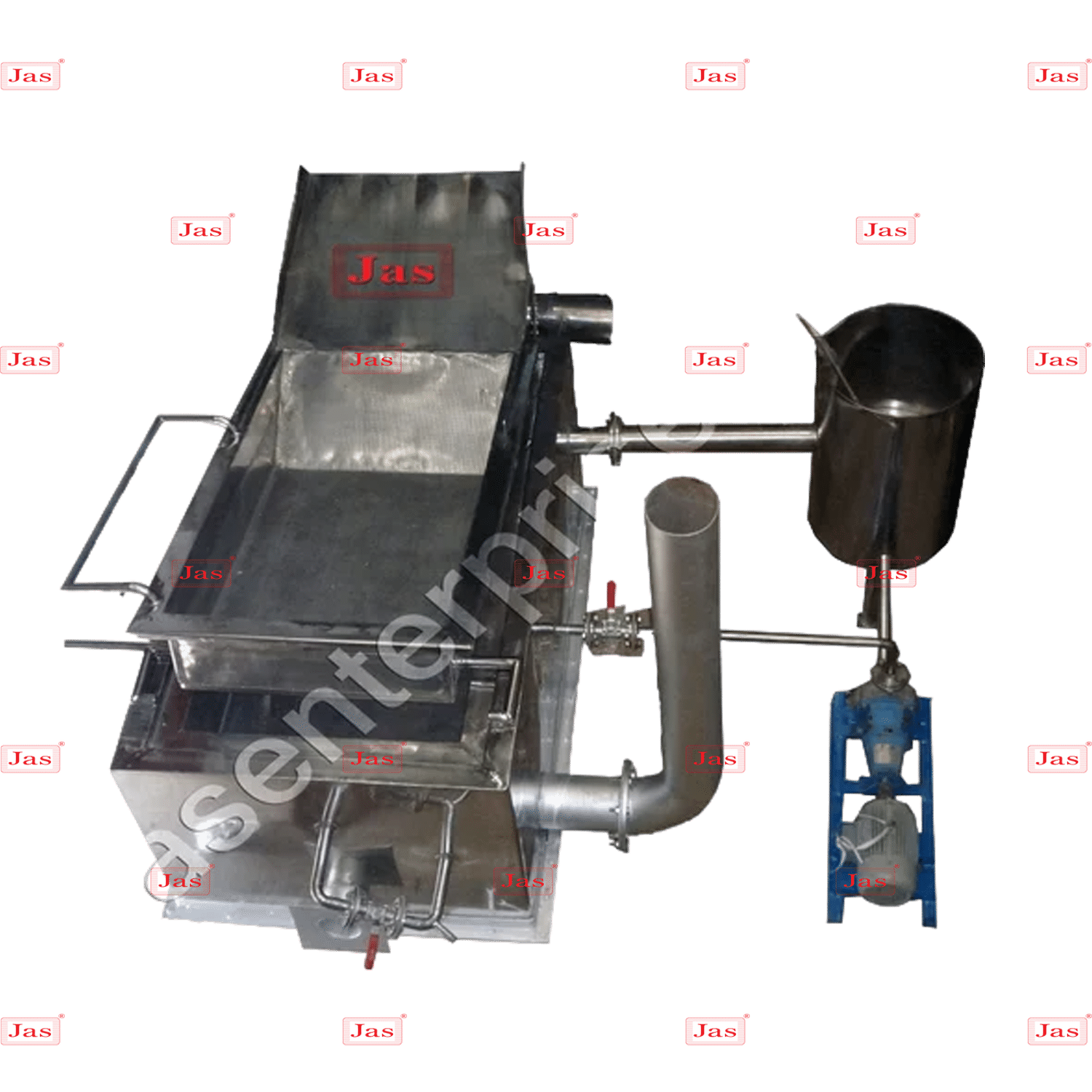

Industrial Frying Equipment

10000 INR/Unit

Product Details:

- Capacity 12-32 Kg/hr

- Automatic Yes

- Voltage 230/440 Volt (v)

- Feature ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- Click to View more

X

Industrial Frying Equipment Price And Quantity

- 10000 INR/Unit

- 1 Unit

Industrial Frying Equipment Product Specifications

- 230/440 Volt (v)

- Yes

- 12-32 Kg/hr

- ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

Industrial Frying Equipment Trade Information

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque Western Union

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- ISO

Product Description

Types of Industrial Frying Equipment

-

Batch Fryers:

- Description: These fryers cook food in batches. They are suitable for small to medium-sized operations.

- Features: Adjustable temperature controls, timers, and sometimes automated lifting systems for baskets.

-

Continuous Fryers:

- Description: Designed for high-volume production, these fryers have a conveyor belt or chain that moves food through the fryer continuously.

- Features: Automated temperature control, filtration systems, and often advanced features for precise cooking and oil management.

-

Deep Frying Stations:

- Description: Integrated systems that may include multiple fryers or compartments, often used in fast-food restaurants.

- Features: High capacity, multiple baskets, and sometimes integrated filtration systems.

-

Vacuum Fryers:

- Description: Operate under reduced pressure to fry foods at lower temperatures, preserving flavors and nutrients better.

- Features: Energy-efficient, often used for high-end products or specialty items.

-

Pressure Fryers:

- Description: Fry food under pressure to cook it faster and often result in a crispier texture.

- Features: Pressure control, temperature regulation, and safety mechanisms.

Key Features to Consider

- Temperature Control: Accurate and consistent temperature management is crucial for quality and safety.

- Filtration Systems: Many fryers include built-in oil filtration to extend oil life and reduce costs.

- Capacity and Size: Depending on your production volume, you may need a fryer that handles a large quantity of food.

- Energy Efficiency: Modern fryers often come with energy-saving features to reduce operational costs.

- Ease of Cleaning: Look for fryers with removable parts or self-cleaning features for convenience and hygiene.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email