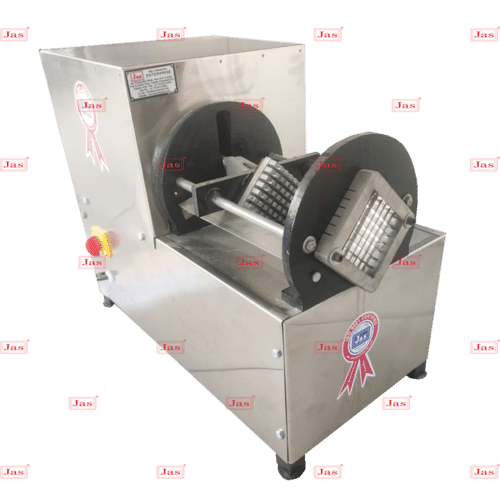

Industrial Finger Chips Machine

20000 INR/Unit

Product Details:

- Capacity 150-200 Kg/hr

- Automatic Yes

- Voltage 230/440 Volt (v)

- Feature ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- Click to View more

X

Industrial Finger Chips Machine Price And Quantity

- 1 Unit

- 20000 INR/Unit

Industrial Finger Chips Machine Product Specifications

- ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- 150-200 Kg/hr

- Yes

- 230/440 Volt (v)

Industrial Finger Chips Machine Trade Information

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque Western Union

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- ISO

Product Description

Key Components:

-

Peeling Unit:

- Function: Removes the skin from potatoes.

- Types: Mechanical peelers or abrasive peelers.

-

Cutting Unit:

- Function: Cuts potatoes into finger chip shapes.

- Types: Blade cutters or rotary cutters.

- Adjustable Sizes: Allows for different thicknesses and sizes of chips.

-

Blanching Unit:

- Function: Blanches the potato strips to preserve color and texture.

- Method: Usually involves hot water or steam.

-

Drying Unit:

- Function: Removes excess moisture from the blanched chips.

- Types: Air dryers or centrifugal dryers.

-

Frying Unit:

- Function: Cooks the chips to achieve the desired crispiness.

- Types: Batch fryers or continuous fryers.

- Temperature Control: Precise control over frying temperature.

-

Cooling Unit:

- Function: Cools the fried chips to stop further cooking and reduce oil content.

- Method: Typically involves air cooling or water cooling.

-

Seasoning and Packaging Unit:

- Function: Adds seasonings and packages the chips.

- Seasoning: Automated seasoning systems for consistent flavor.

- Packaging: Various packaging options, from bags to boxes, often automated.

Key Features:

- Capacity: Machines vary in capacity, from small-scale units suitable for restaurants to large-scale systems for industrial production.

- Automation: Modern machines are often fully automated, reducing labor costs and increasing efficiency.

- Adjustability: Many machines offer adjustable settings for different potato varieties and chip sizes.

- Ease of Cleaning: Designed for easy cleaning to maintain hygiene standards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email