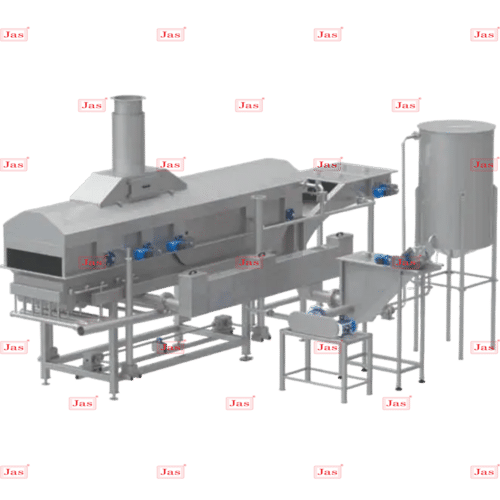

Industrial Continuous Potato Chips Fryer

Product Details:

- Capacity 500 Kg/hr

- Automatic Yes

- Voltage 230/440 Volt (v)

- Feature ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- Click to View more

Industrial Continuous Potato Chips Fryer Price And Quantity

- 1750000 INR/Unit

- 1750000.00 - 2420000.00 INR/Unit

- 1 Unit

Industrial Continuous Potato Chips Fryer Product Specifications

- 500 Kg/hr

- ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- 230/440 Volt (v)

- Yes

Industrial Continuous Potato Chips Fryer Trade Information

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque Western Union

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- ISO

Product Description

-

Continuous Operation: These fryers are designed to operate continuously, allowing for a consistent output of fried potato chips without interruptions in the production line.

-

Conveyor Belt System: Potato chips are fed into the fryer via a conveyor belt system that moves them through the fryer at a controlled pace. This ensures uniform frying and prevents overcrowding or uneven cooking.

-

Oil Heating and Circulation: The fryer maintains a large quantity of cooking oil at a precise temperature using heating elements and circulation systems. This temperature control is crucial for achieving the desired texture and flavor of the potato chips.

-

Oil Filtration and Management: Industrial fryers often include systems for filtering and managing the cooking oil. This helps to extend the oil's lifespan, maintain product quality, and reduce operating costs.

-

Adjustable Speed and Temperature: Operators can typically adjust the speed of the conveyor belt and the temperature of the oil to accommodate different types of potato chips and production requirements.

-

Safety Features: These fryers incorporate various safety features such as automatic shut-off mechanisms, temperature sensors, and guards to protect workers and prevent accidents.

-

Cleaning and Maintenance: Regular cleaning and maintenance are essential to ensure hygiene and prolong the fryer's lifespan. Many industrial fryers are designed with easy-to-clean components and access points.

-

Capacity and Output: The capacity of these fryers can vary significantly depending on the model and manufacturer, ranging from hundreds to thousands of kilograms of potato chips per hour.

-

Energy Efficiency: Modern industrial fryers often incorporate energy-efficient technologies to reduce operational costs and environmental impact.

-

Control Systems: Advanced control systems may be included to monitor and adjust parameters such as oil temperature, frying time, and conveyor speed automatically.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+