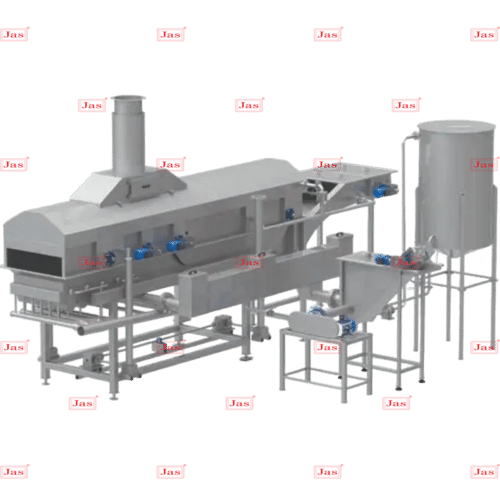

Industrial Automatic Snack Frying Machine

Price 1750000 INR/ Unit

Industrial Automatic Snack Frying Machine Specification

- Capacity

- 500 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Industrial Automatic Snack Frying Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Industrial Automatic Snack Frying Machine

-

Frying Chamber: This is where the snacks are fried. It typically includes a heating element or fryer that can be heated to precise temperatures. The chamber is often equipped with a conveyor belt or basket system to move snacks through the oil.

-

Oil Filtration System: To maintain oil quality and reduce the frequency of oil changes, these machines often include an oil filtration system. This system helps remove impurities and food particles from the oil.

-

Temperature Control: Precise temperature control is essential for consistent frying results. Many machines come with digital temperature controls and sensors to monitor and adjust the frying temperature automatically.

-

Conveyor System: An automatic conveyor system moves the snacks through the fryer. The speed of the conveyor can usually be adjusted to control frying time and ensure even cooking.

-

Oil Reservoir: The reservoir holds the frying oil. Some machines have a separate heating unit to keep the oil at the desired temperature.

-

Cooling System: After frying, snacks often need to be cooled before packaging. Some machines include a cooling conveyor or air blower to help with this process.

-

Control Panel: The control panel allows operators to set frying times, temperatures, and other parameters. It may also include diagnostics and maintenance alerts.

-

Cleaning Mechanism: Given the nature of frying, regular cleaning is necessary. Many machines are designed with removable parts and cleaning cycles to simplify maintenance.

-

Safety Features: Safety is critical in industrial machines. Features may include automatic shut-off systems, overheat protection, and emergency stop buttons.

-

Energy Efficiency: Modern machines are often designed to be energy-efficient to reduce operational costs and environmental impact.

Eco-Friendly & Efficient Snack Production

Designed to minimize environmental impact, this frying machine prioritizes low energy consumption and reduced noise, making it suitable for various industrial settings. Its advanced features help companies decrease operational costs while maintaining productivity and product quality.

Built for Versatility and Scale

With a substantial capacity of 500 kg/hr and automatic controls, the machine handles high-volume production seamlessly. The compact structure ensures space optimization without compromising on performance or output consistency, fitting well into both small and large-scale operations.

FAQs of Industrial Automatic Snack Frying Machine:

Q: How does the Industrial Automatic Snack Frying Machine contribute to energy savings?

A: This machine uses advanced ECO-friendly technology and efficient heating systems to lower energy consumption significantly. By optimizing heat distribution and recovery, it reduces overall operational costs while maintaining high frying standards.Q: What types of snacks can be processed with this machine?

A: The machine is versatile and suitable for a wide range of snacks including chips, namkeen, pellets, and other fried items, making it an excellent choice for manufacturers looking to diversify their product range.Q: When is the ideal time to implement this machine in a production line?

A: The best time to introduce this frying machine is when scaling up production or upgrading to more sustainable equipment. Its automation and efficiency support growing operational demands and compliance with eco-friendly objectives.Q: Where can this automatic frying machine be installed?

A: Thanks to its compact design, the machine can be installed in various settingsfrom small factory floors to large industrial kitchens throughout India, offering flexibility in plant layout and expansion.Q: What is the process for operating the machine automatically?

A: Once snacks are loaded, the operator sets the desired parameters and initiates the process. The automated system manages frying duration, temperature, and oil circulation, delivering consistent results with minimal manual oversight.Q: What are the usage benefits for wholesalers, distributors, and exporters in India?

A: With its high capacity and reliability, the machine enables consistent bulk production, supporting prompt order fulfillment and improving supply chain efficiency. Its robust design also reduces downtime, which is essential for large-scale commercial operations.Q: How does the compact structure of the machine benefit snack manufacturers?

A: A space-saving footprint allows for easy integration into existing production lines, reducing real estate requirements while maintaining robust output, making it ideal for manufacturers with limited processing area.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Precision Vegetable Cutting Machine

Price 16000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 230/440 Volt (v)

Capacity : 101000 Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Haldi Drying Machine

Price 132000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Capacity : 120kg Kg/hr

Renewable Energy Food Dehydrators

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 30 to 2500 Kg/hr

Makhana Roasting And Flavouring Machines

Price 145000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Capacity : 10500 Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free