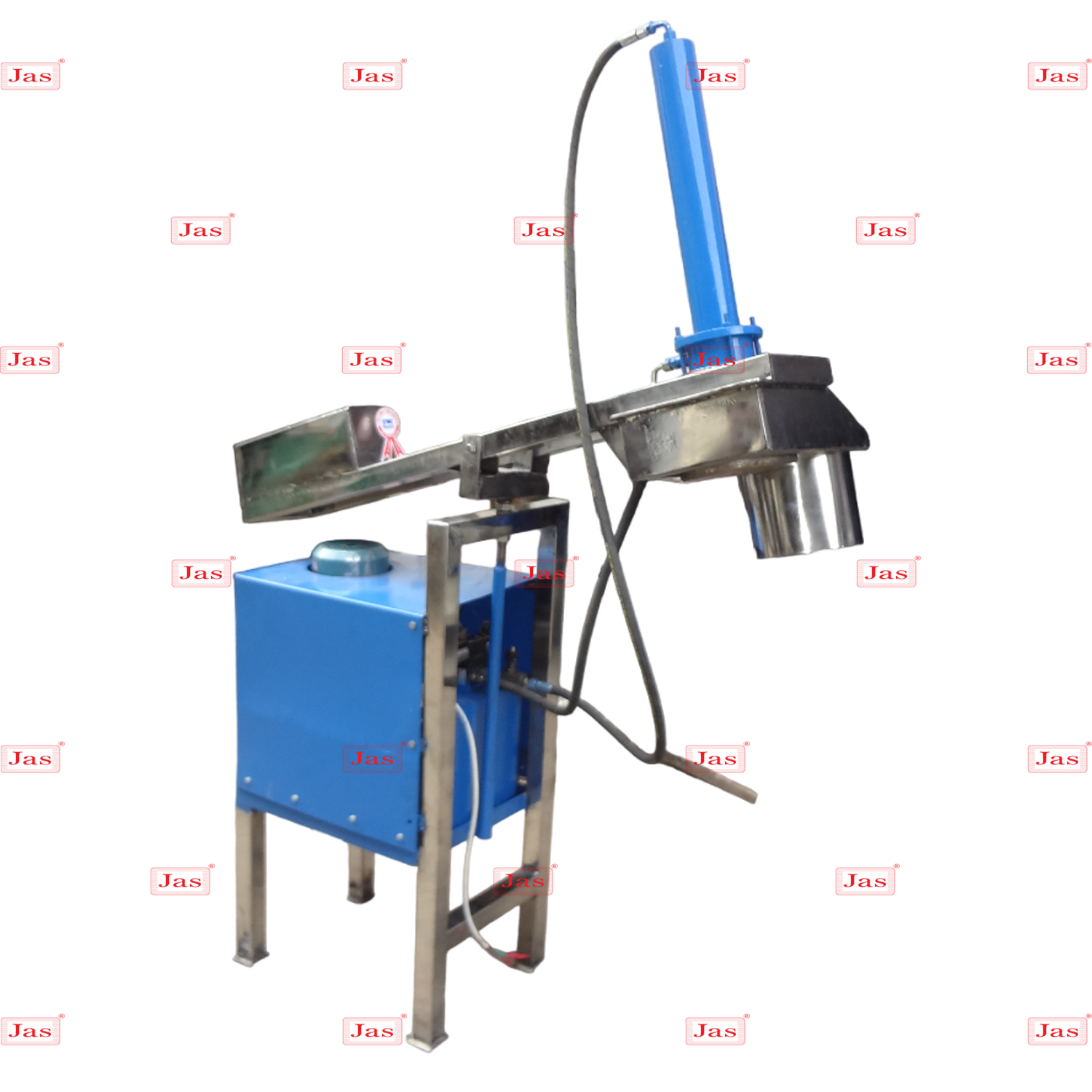

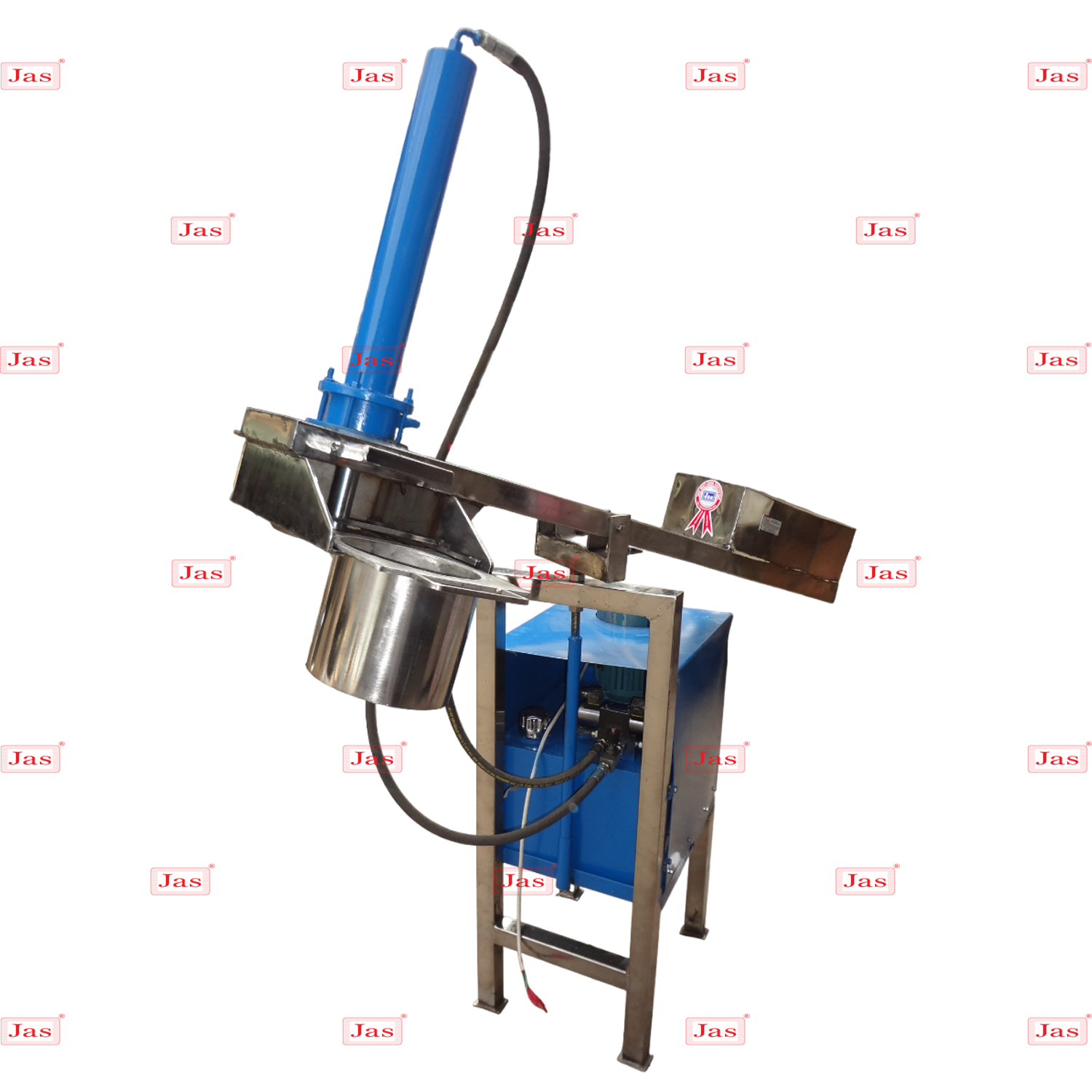

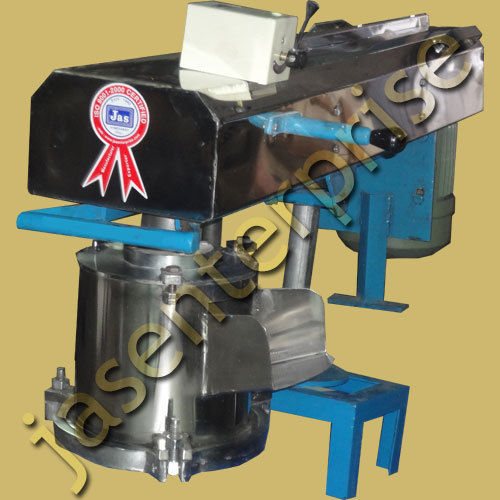

Hydraulic Namkeen Machine

Product Details:

- Capacity 45-100 Kg/hr

- Automatic Yes

- Voltage 230/440 Volt (v)

- Feature ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- Click to View more

Hydraulic Namkeen Machine Price And Quantity

- 1 Unit

- 85000 INR/Unit

Hydraulic Namkeen Machine Product Specifications

- Yes

- 230/440 Volt (v)

- ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- 45-100 Kg/hr

Hydraulic Namkeen Machine Trade Information

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque Western Union

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- ISO

Product Description

-

Hydraulic System: The hydraulic system in the machine provides the necessary force to press or extrude the namkeen mixture. This system uses hydraulic pressure to ensure consistent and precise production.

-

Extrusion and Shaping: The machine often includes an extrusion mechanism that shapes the namkeen mixture into various forms, such as sticks, rings, or pellets. This process involves forcing the mixture through molds or dies.

-

Heating: Many hydraulic namkeen machines come with built-in heating elements or compartments for frying the namkeen. This ensures that the namkeen is cooked evenly and achieves the desired crispiness.

-

Adjustable Settings: The machine usually has adjustable settings for temperature, pressure, and speed, allowing for customization based on the specific recipe and desired texture of the namkeen.

-

Material: Typically, the machine is made from high-quality stainless steel to ensure durability and ease of cleaning.

-

Capacity: Hydraulic namkeen machines vary in size and capacity, from small models suitable for small-scale production to larger models designed for industrial-scale operations.

How It Works

-

Preparation: The namkeen mixture, which includes ingredients like flour, spices, and other flavorings, is prepared and loaded into the machine.

-

Extrusion: The hydraulic system applies pressure to the mixture, forcing it through molds or dies to shape it into the desired form.

-

Cooking: Depending on the machine, the shaped namkeen may be cooked through frying or baking within the machine.

-

Cooling and Packaging: After cooking, the namkeen is cooled and then packaged for distribution.

Benefits

- Consistency: Hydraulic pressure ensures that each batch of namkeen has a uniform texture and shape.

- Efficiency: The machine speeds up production compared to manual methods, making it suitable for larger quantities.

- Customizability: Adjustable settings allow for different shapes, sizes, and textures of namkeen.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+