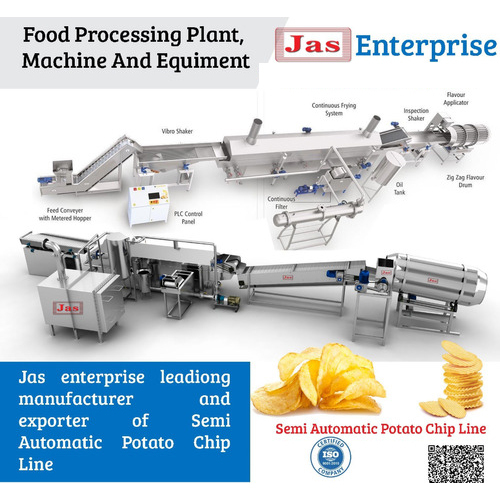

Tapioca Chip Making Machine

उत्पाद विवरण:

- ऑटोमेशन ग्रेड Automatic

- पावर सोर्स Electric

- सामान्य उपयोग Commercial'

- मटेरियल

- क्षमता किलो/घंटा

- कम्प्यूटरीकृत

- ऑटोमेटिक

- अधिक देखने के लिए क्लिक करें

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- Electric

- 1 Year

- Commercial'

- किलो/घंटा

- Automatic

- वोल्ट (v)

व्यापार सूचना

- प्रति महीने

- हफ़्ता

- ISO

उत्पाद वर्णन

-

Automation: These machines are usually fully automated or semi-automated, designed to streamline the production process of tapioca chips. They can handle large volumes efficiently, making them suitable for commercial production.

-

Processing Steps: The machine generally performs several key steps in the production process, including slicing the tapioca roots into thin slices, frying or baking the slices to make them crispy, and seasoning or flavoring the chips if desired.

-

Capacity: Depending on the model and size, these machines can produce a range of output capacities per hour. Industrial-scale machines can produce thousands of kilograms of tapioca chips daily.

-

Material Handling: They are equipped with conveyors and handling systems to move raw materials (tapioca roots or pre-processed tapioca slices) through various stages of production, including slicing, frying, and packaging.

-

Quality Control: Modern machines often include features for monitoring and controlling parameters such as frying temperature, frying time, seasoning application, and product consistency to ensure high-quality chips.

-

Customization Options: Some machines offer flexibility in terms of chip thickness, frying time, and seasoning application, allowing manufacturers to adjust production to meet different market preferences.

-

Cleaning and Maintenance: Like any industrial equipment, tapioca chip making machines require regular cleaning and maintenance to ensure optimal performance and hygiene standards.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+