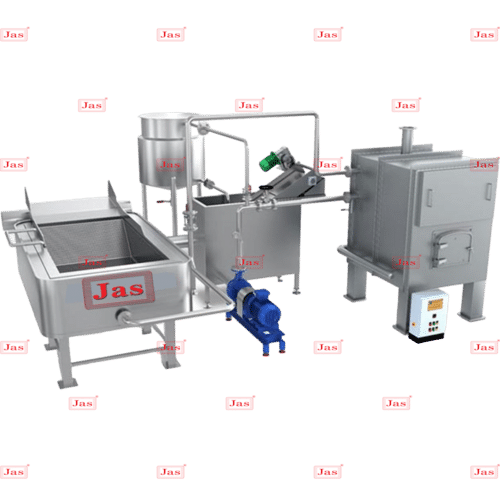

Industrial Batch Fryer

उत्पाद विवरण:

- क्षमता लीटर/घंटा

- ऑटोमेटिक

- वोल्टेज वोल्ट (v)

- फ़ीचर

- अधिक देखने के लिए क्लिक करें

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- लीटर/घंटा

- वोल्ट (v)

व्यापार सूचना

- ISO

उत्पाद वर्णन

-

Capacity: Industrial batch fryers come in various sizes, from smaller units that handle a few hundred pounds of food per batch to large models that can process thousands of pounds.

-

Heating System: They typically use gas or electric heating elements to reach and maintain the high temperatures required for frying. Some models may use oil heaters or direct flame.

-

Temperature Control: Precise temperature control is crucial for achieving consistent results and ensuring food safety. Most batch fryers come with adjustable thermostats and digital controls.

-

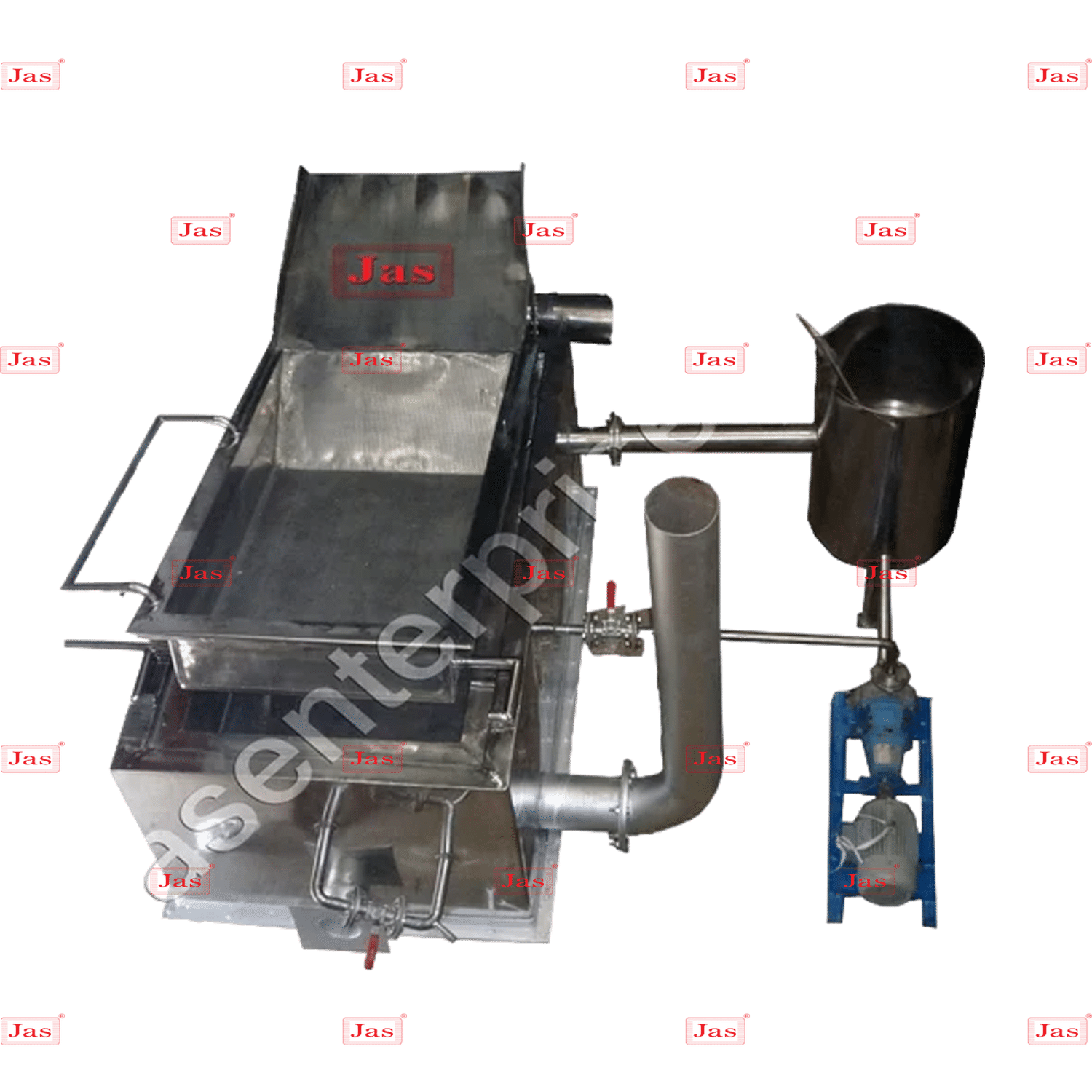

Oil Filtration: Many industrial fryers are equipped with oil filtration systems to extend the life of the oil and maintain the quality of the fried products.

-

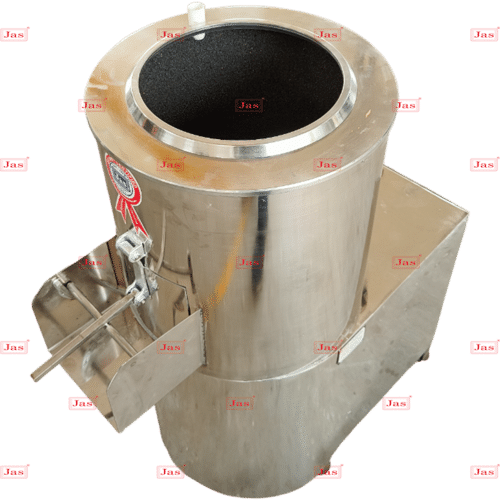

Basket and Racking Systems: Batch fryers often use baskets or racks to hold the food while it fries. These systems can be manually or automatically operated, depending on the model.

-

Cooling and Draining: After frying, the food needs to be cooled and drained. Some fryers have built-in systems for this, while others may require separate equipment.

-

Safety Features: These can include automatic shut-off systems, over-temperature alarms, and safety guards to prevent accidents.

-

Ease of Cleaning: Since frying involves oil, which can be messy, many industrial fryers are designed for easy cleaning with features like removable parts and smooth surfaces.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+