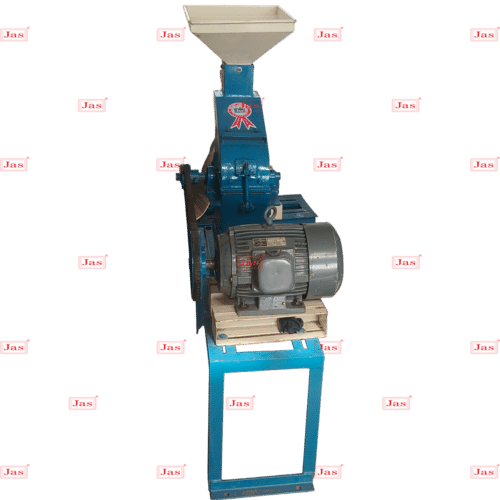

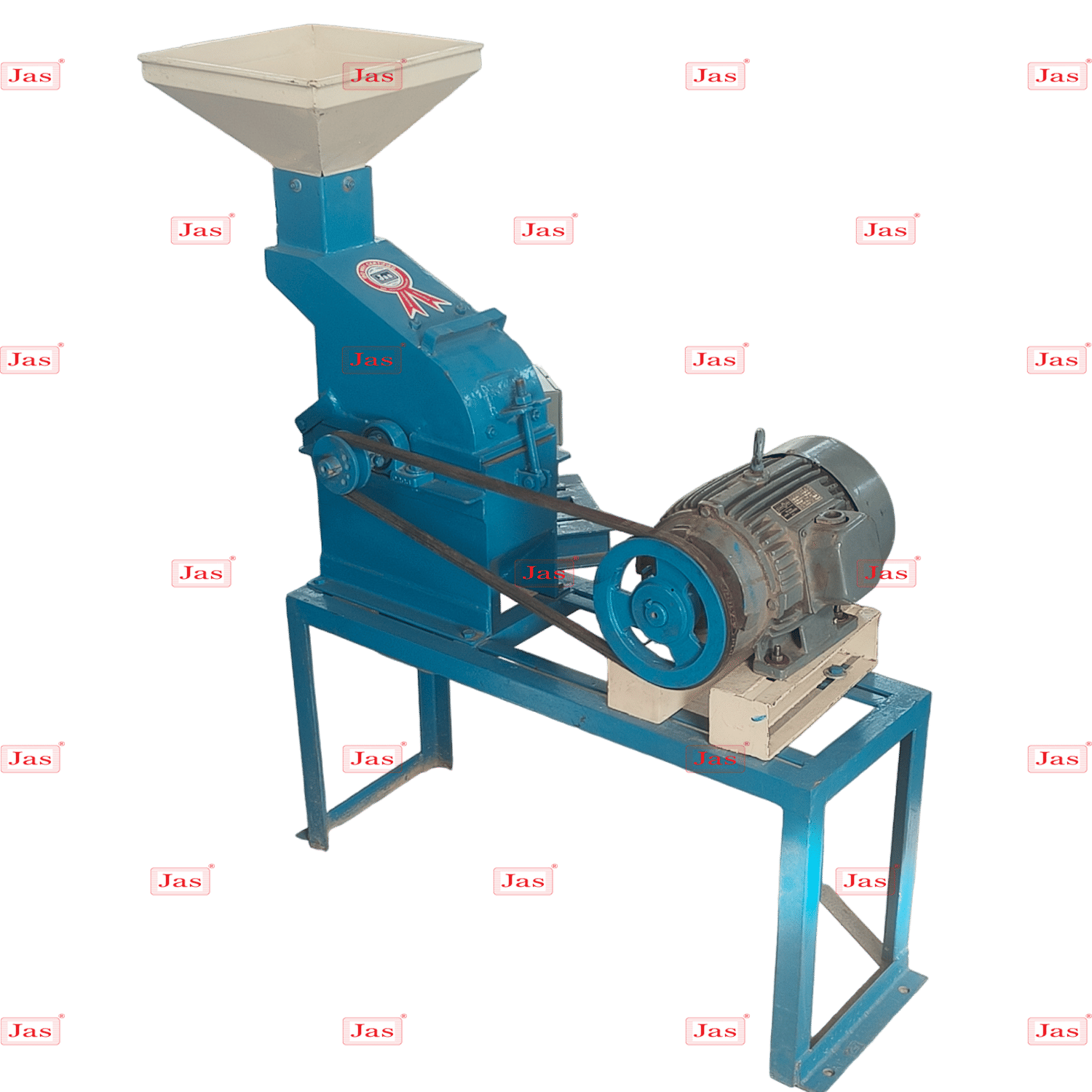

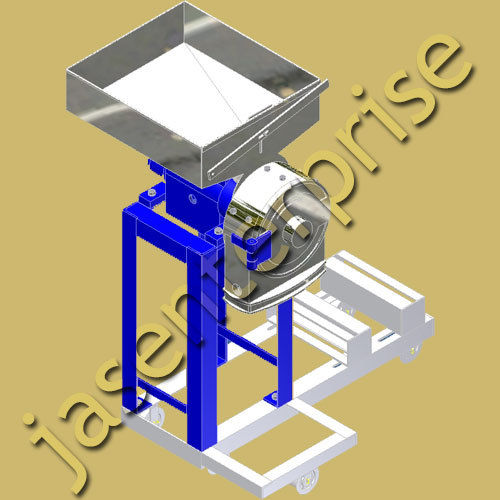

Full Circle Hammer Mill

18000 आईएनआर/Unit

उत्पाद विवरण:

- क्षमता किलो/घंटा

- ऑटोमेटिक

- वोल्टेज वोल्ट (v)

- फ़ीचर

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- किलो/घंटा

- वोल्ट (v)

व्यापार सूचना

- ISO

उत्पाद वर्णन

How It Works

Material Feeding Raw materials are fed into the mill through a hopper

Impact Grinding The rotating hammers impact the material breaking it down into smaller particles

Screening The ground material passes through a screen with specific mesh sizes determining the final particle size The screen helps in controlling the fineness of the ground product

Discharge The processed material is then discharged from the mill usually via an outlet

Key Features

Full Circle Design This means the hammers are positioned around the entire circumference of the mill chamber This design helps to ensure a more uniform grind and efficient use of the hammers

Versatility Capable of handling a wide range of materials from grains to wood chips depending on the size and type of the mill

Efficiency The full circle design maximizes the use of the hammers surface area leading to higher efficiency and reduced energy consumption compared to other types of hammer mills

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email