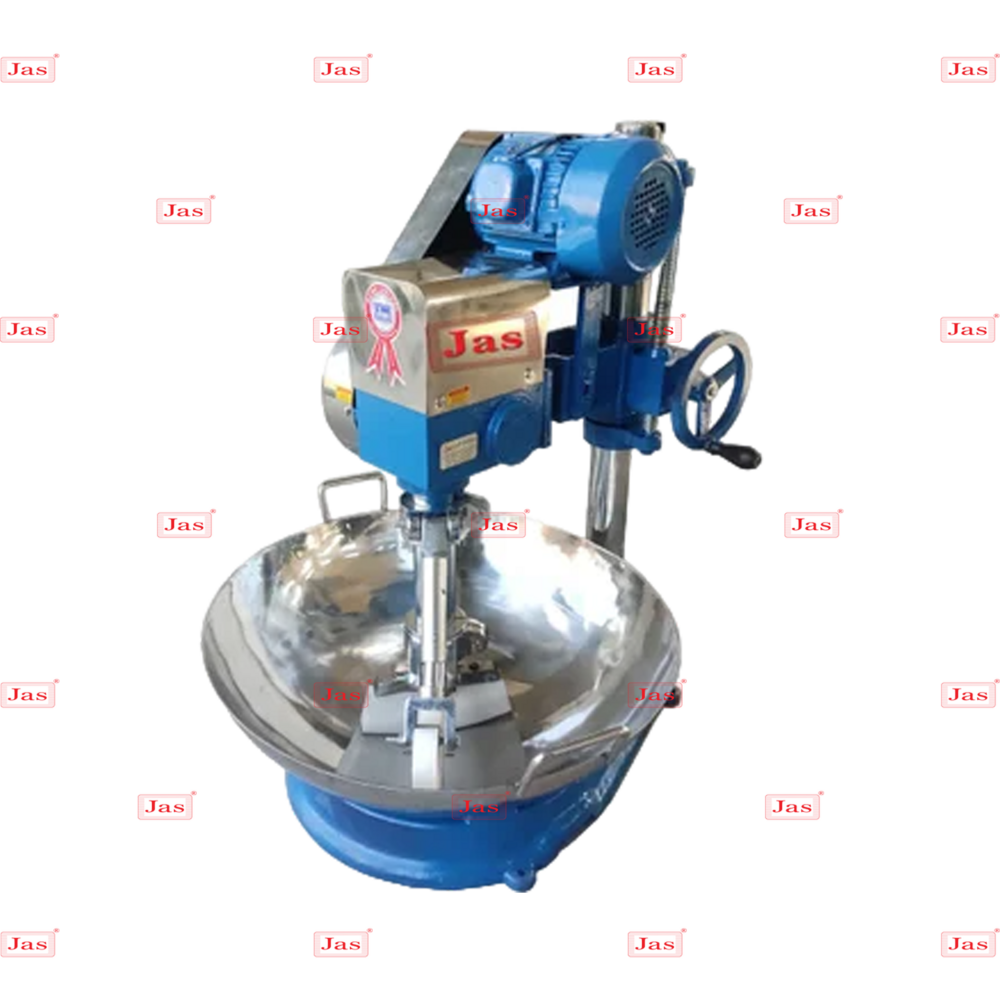

Halwa Making Machine

Halwa Making Machine Specification

- General Use

- all types of halwa like munghalwa, karachi halwa, tirunelvelihalwa, bombay halwa, ice halwa, besan, atta, all types of burfis, mysorepak, mohanthal, kajubite, jelly, slurry, dalpinni, dodhabarfi, mava making etc.

- Computerized

- No

- Automatic

- Yes

- Control System

- Manual

- Installation Type

- Free Stand

- Voltage

- 110-415 Volt (v)

- Power

- 1 - 3 Horsepower (HP)

- Feature

- Lower Energy Consumption, ECO Friendly, Low Noice, High Efficiency, Compact Structure

- Warranty

- One year against manufacturing defects at our site, except all wear and tear parts.

Halwa Making Machine Trade Information

- Minimum Order Quantity

- 01 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Units Per Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, Uttarakhand, Daman and Diu, Lakshadweep, East India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Kerala, Haryana, Delhi, Gujarat, South India, North India, Andhra Pradesh, Central India, Odisha, West India, Chhattisgarh, Uttar Pradesh, All India

- Certifications

- ISO 9001

About Halwa Making Machine

It works on principle of baking while stirring. Two agitator arms continuously turn, twist, shake & bake material in all direction in bowl. Machine will bake the material evenly. It can be used as a mixing machine to mix materials, slurry, liquids etc.

Is useful for baking all types of halwa like mung halwa, Karachi halwa, Tirunelveli halwa, Bombay halwa, ice halwa, besan, atta, all types of burfis, Mysore pak, mohan thal, kaju bite, jelly, slurry, dalpinni, doda barfi, mava making etc.

Versatile Sweets Preparation

This halwa making machine accommodates the preparation of diverse Indian sweets, from halwas like moong, Karachi, and Tirunelveli, to burfis, mysorepak, and even jelly or mava. Its flexibility makes it ideal for commercial kitchens, sweet shops, and large-scale food production establishments.

Energy Efficient and Environmentally Conscious

Engineered with a focus on reducing energy consumption, the manual-control system ensures precise operation while maintaining an eco-friendly approach. The compact structure saves valuable kitchen space, and the low noise output contributes to a more pleasant working environment.

Simple Installation and Reliable Operation

This machine features a straightforward, free-standing installation process. Designed for reliability, its robust construction provides high efficiency, while a comprehensive one-year onsite warranty (excluding wear and tear) underlines the manufacturers commitment to quality and customer satisfaction.

FAQs of Halwa Making Machine:

Q: How does the Halwa Making Machine simplify the halwa preparation process?

A: The machine streamlines halwa preparation by automating mixing and cooking, ensuring consistent texture and preventing burning. Its manual control system lets operators adjust settings for optimal results, significantly reducing labor time and physical effort.Q: What types of products can be made using this halwa machine?

A: This equipment is suitable for producing various sweets such as all types of halwas (moong, Karachi, Tirunelveli, Bombay, ice halwa), assorted burfis, mysorepak, kaju bite, jelly, mava, mohanthal, and more, making it a versatile asset for any sweet manufacturing unit.Q: When should maintenance be performed on the machine?

A: Routine maintenance is recommended every few months or after intensive use to ensure smooth operation. Regular checks of moving parts and cleaning post-production help maintain performance and extend the machines life.Q: Where can the Halwa Making Machine be installed?

A: Thanks to its compact and free-standing design, the machine can be installed in commercial kitchens, sweet shops, factories, or any food production facility, provided there is a suitable power supply (110415V) available.Q: How does the machine contribute to energy efficiency and a quieter workspace?

A: The machines lower power consumption (13 HP) and advanced mechanical design result in less electricity usage and minimal noise, creating a quieter, energy-saving work environment.Q: What are the benefits of using this machine for sweet production?

A: Operators enjoy higher efficiency, consistent product quality, lower energy use, and reduced manual effort. The eco-friendly design and space-saving structure further benefit any food production venture.Q: Is there a warranty, and what does it cover?

A: Yes, a one-year warranty covers manufacturing defects at the installation site, excluding normal wear and tear parts, ensuring dependable service and support for commercial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sweets Making Machine Category

Steam Kadai Type Khoa Machine

Price 67500 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 230 Volt (v)

Capacity : 32150 Ltr/hr

Warranty : One year against manufacturing defect at our side

Khoya Bhatti

Price 67500 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 220 Volt (v)

Warranty : One year against manufacturing defect at our side

Mawa And Basundi Making Machine

Minimum Order Quantity : 1 Unit

Capacity : 5 to 200 per Batch Kg/day

Warranty : One year against manufacturing defects at our site, except all wear and tear parts.

Kaju Muska Machine

Price 68000 INR / Piece

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 230 Volt (v)

Capacity : 1015 kg/betch Pcs/hr

Warranty : One year against manufacturing defect at our side

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS