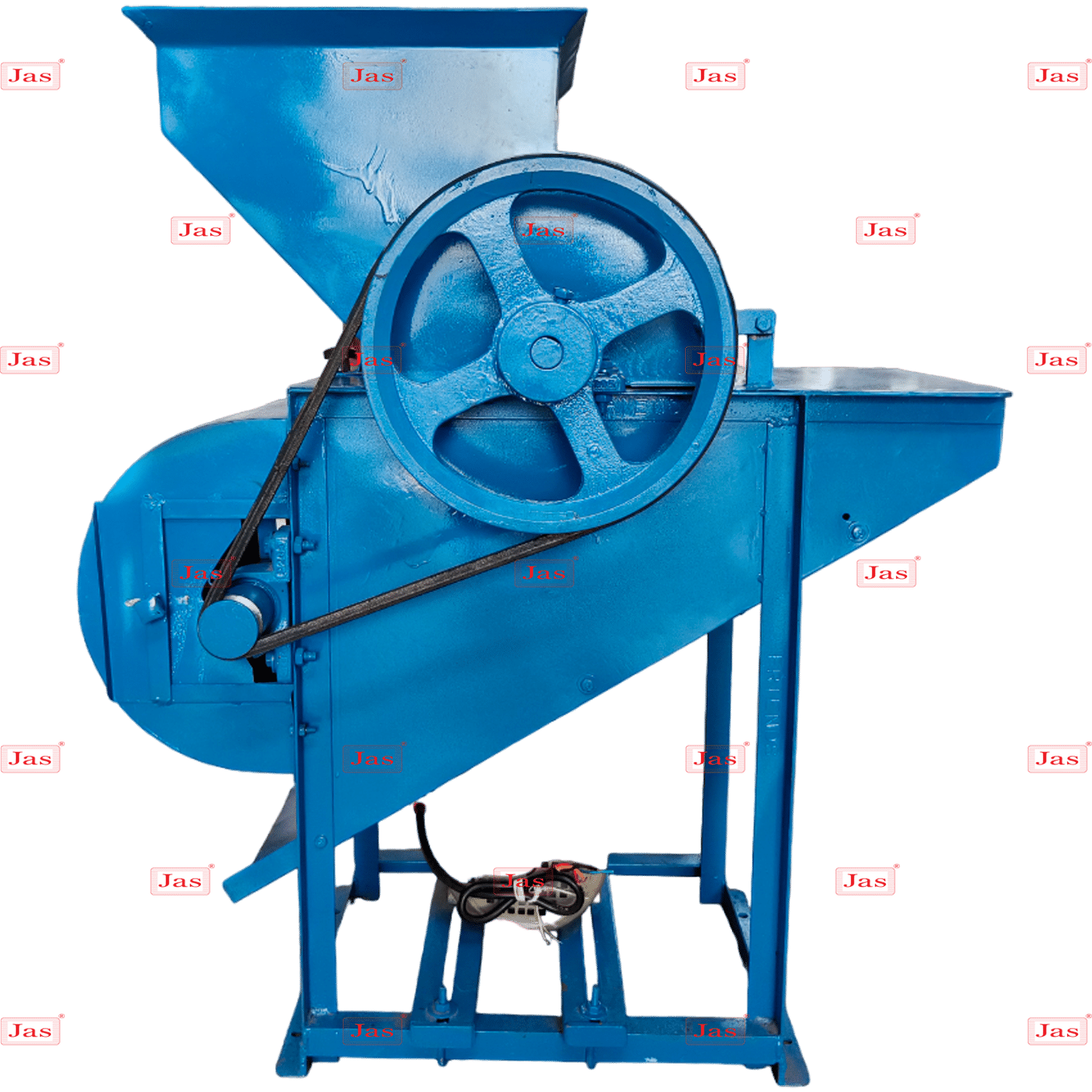

Groundnut Peeling Machine

Product Details:

- Capacity 100-150 Kg/hr

- Automatic Yes

- Voltage 230/440 Volt (v)

- Power 1 Horsepower (HP)

- Feature ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- Click to View more

Groundnut Peeling Machine Price And Quantity

- 1 Unit

- 49500 INR/Unit

Groundnut Peeling Machine Product Specifications

- Yes

- ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- 230/440 Volt (v)

- 1 Horsepower (HP)

- 100-150 Kg/hr

Groundnut Peeling Machine Trade Information

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque Western Union

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- ISO

Product Description

Types of Groundnut Peeling Machines

-

Dry Peeling Machines: These use mechanical friction or abrasion to remove the skin. They are often used for small to medium-sized operations.

-

Wet Peeling Machines: These involve soaking the peanuts in water and then removing the skins. This method is common in large-scale operations and can be more effective for thorough peeling.

-

Air-Suction Peeling Machines: These machines use air pressure to separate the skin from the peanuts. They are known for their efficiency and minimal damage to the nuts.

-

Rotary Peeling Machines: These machines use a rotating drum with abrasive surfaces to peel the peanuts. They are often used in commercial settings due to their capacity and speed.

Features to Look For

-

Capacity: Depending on your needs, choose a machine with the right capacity. Smaller machines are suitable for home or small business use, while larger machines are designed for industrial purposes.

-

Efficiency: Look for machines with high peeling efficiency and minimal breakage of peanuts.

-

Ease of Cleaning: Machines with removable parts or easy-to-clean designs can save time and maintain hygiene.

-

Durability: Ensure the machine is made from high-quality materials to withstand the demands of continuous use.

-

Adjustability: Some machines offer adjustable settings for different types of peanuts and peeling requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+