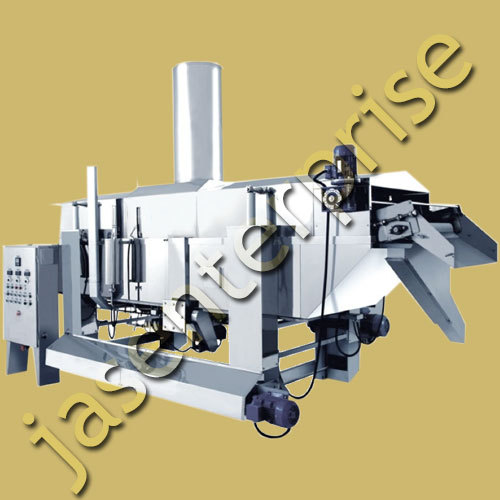

continuous namkeen fryer

50000 INR/Unit

Product Details:

- Material Stainless Steel

- Capacity 325 -350 Kg/hr

- Voltage 415 Volt (v)

- Power 750-1500 Watt (w)

- Click to View more

X

continuous namkeen fryer Price And Quantity

- 50000 INR/Unit

- 1 Unit

continuous namkeen fryer Product Specifications

- 750-1500 Watt (w)

- 415 Volt (v)

- Stainless Steel

- 325 -350 Kg/hr

continuous namkeen fryer Trade Information

- 1000 Unit Per Month

- 1 Months

Product Description

Owing to our vast knowledge in this domain, we are able to manufacture and export best quality continuous Namkeen fryer. Our well-trained professionals manufacture these fryers in our well-equipped infrastructure facility by making use of modern tools and machines. We manufacture these fryers keeping in mind the industry laid parameters, therefore using top quality stainless steel and other components. Owing to its high performance and longer service life, the continuous Namkeen fryer is highly appreciated by our patrons.Advance Features of Continuous fryer with heat exchanger

- Complete system consists of frying section with paddles and sub merger belt, top hood, takeout belt, continuous oil filter, day oil tank and heat exchanger.

- Make up oil is continuously added to the fryer to maintain optimum level.

- The flow of oil ensures a linear flow of oil, which is necessary in order to have a uniform frying time for all the slices.

- The equipment is designed to have a low oil holding capacity (325 -350 liter) in order to achieve low oil turnover ratio.

- Speed of both the belts can be varied by a variable frequency drive to adjust the frying time. Similarly flow of inlet oil can be regulated with valves.

- The continuous oil filtration is carried out by a belt type filter, which keeps the frying oil clean and filtered particles are collected in a tray.

- A stainless steel 304 made oil tank is placed with the fryer which can accommodate entire oil in the system.

- After frying the Namkeen, farsan are received by takeout belt.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email