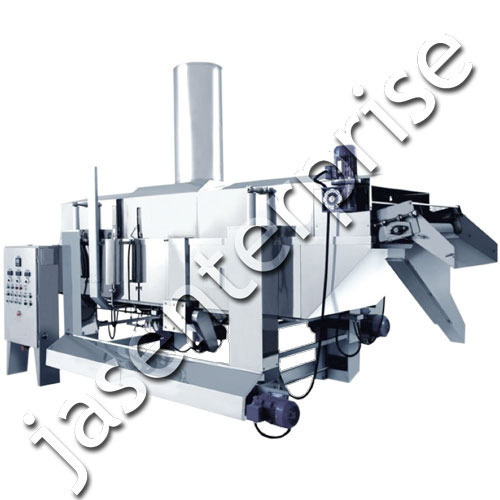

Continuous Frying Systems

Product Details:

- Material Stainless Steel

- Capacity 300 to 350 Kg/hr

- Computerized No

- Automatic Yes

- Control System Manual

- Voltage 110-440 Volt (v)

- Power 8 Horsepower (HP)

- Click to View more

Continuous Frying Systems Price And Quantity

- 1 Unit

- 1800000.00 - 10000000.00 INR/Unit

Continuous Frying Systems Product Specifications

- 110-440 Volt (v)

- 8 Horsepower (HP)

- ECO Friendly Low Noice Lower Energy Consumption High Efficiency Compact Structure

- Stainless Steel

- Yes

- No

- 300 to 350 Kg/hr

- Manual

- 1 Year Against Manufacturing Defect At Our Site

Continuous Frying Systems Trade Information

- Ahmedabad

- 1000 Unit Per Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Dadra and Nagar Haveli Chandigarh Tripura Meghalaya Arunachal Pradesh Daman and Diu South India Central India North India East India West India Andaman and Nicobar Islands Andhra Pradesh Assam Bihar Chhattisgarh Goa Haryana Himachal Pradesh Jammu and Kashmir Jharkhand Karnataka Kerala Lakshadweep Madhya Pradesh Mizoram Manipur Nagaland Pondicherry Odisha Punjab Rajasthan Sikkim Tamil Nadu Telangana Uttarakhand West Bengal Maharashtra Delhi Gujarat Uttar Pradesh All India

- ISO 9001

Product Description

Continuous Frying Systems

The multipurpose frying system is exclusively designed for Indian Namkeen's and Snacks. Less oil circulates in the system for better oil management and fast turnover. The frying system is proven and working satisfactorily with top brand Namkeen manufacturers of India & abroad.

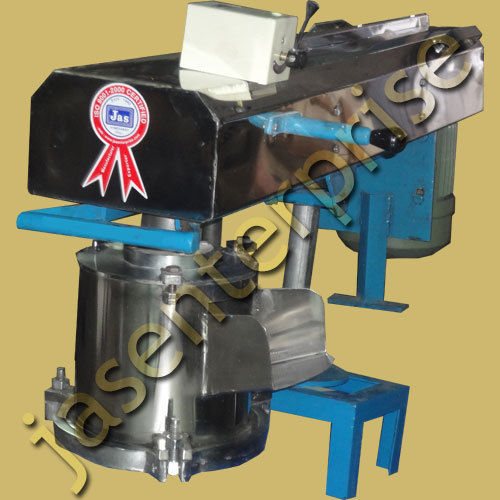

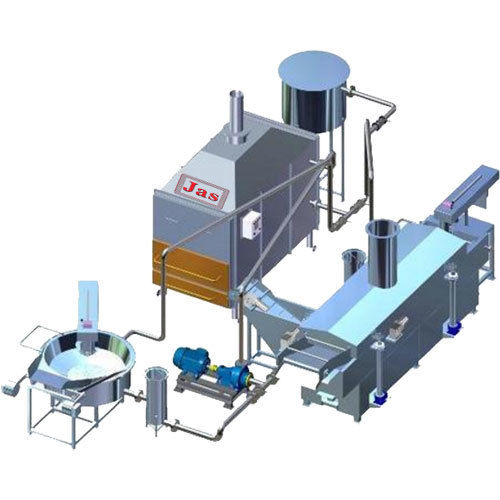

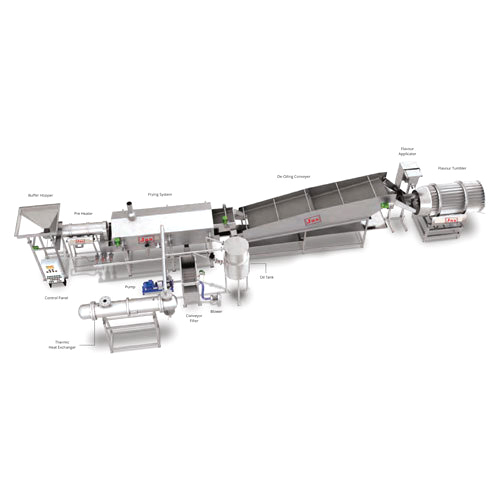

A Continuous frying system for continuously frying banana chips and other snack foods such as sev, bhujia, Bikaner sev, Ratlami sev, aloo Sev, tomato Sev, spinach sev, Lushan sev, Ganthia, tum tum, nylon sev, sada sev, papadi, ganthia,fulvadi et cetera, Farali chevda, are compact, easily cleaned and serviced, and automatically controlled at an external control Panel. The unit consists of an elongated frying kettle covered by a hood and having, optionally, a slicer at an entrance end. A product delivery conveyor is disposed at an exit end. Twin paddle wheels are provided within the kettle for moving up and down the sliced product as it enters an oil bath therein. Downstream of the paddle wheels a submersion conveyor is provided having depending fries mutually spaced there along for conveying the product through the oil bath to the delivery conveyor at the exit end. The entire product conveyor system, paddle wheels and conveyors may be pivoted upwardly as a unit, out of the kettle, by a linear actuator mounted on the external side thereof. A flexible drive coupling is provided to facilitate this pivotal movement. Oil within the kettle may be re circulated through a heat exchanger. Separately, oil within the kettle may be re circulated through a filter, and an oil level within the kettle is maintained automatically by an internal sensor which controls a filling means.

Standard Capacities (kg/hr):- 150, 250, 500, 750.

- Superior and consistent product

- Better oil management and economics

- Automatic and precise process controls

- Easy installation, simple operation

- Sanitary design

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+