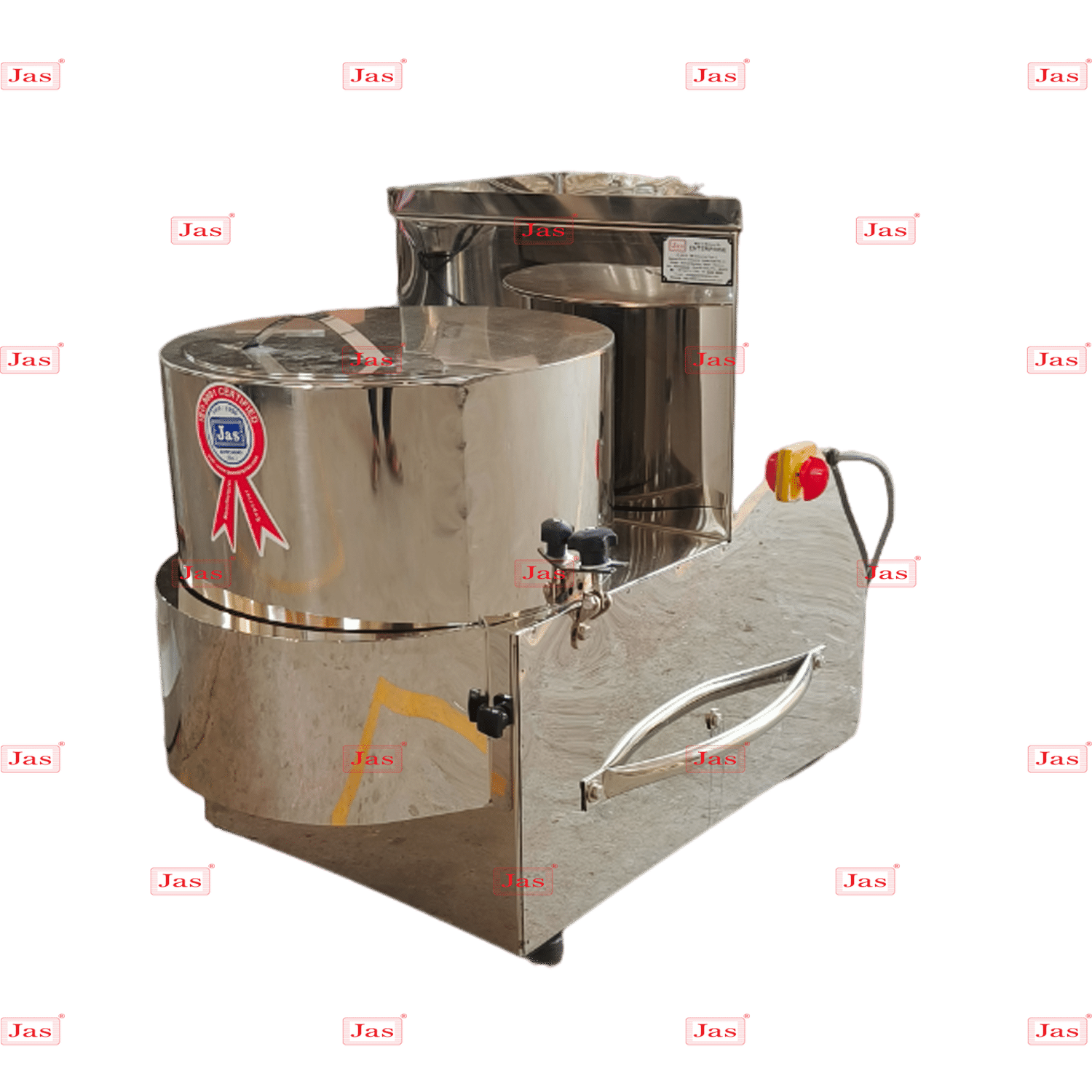

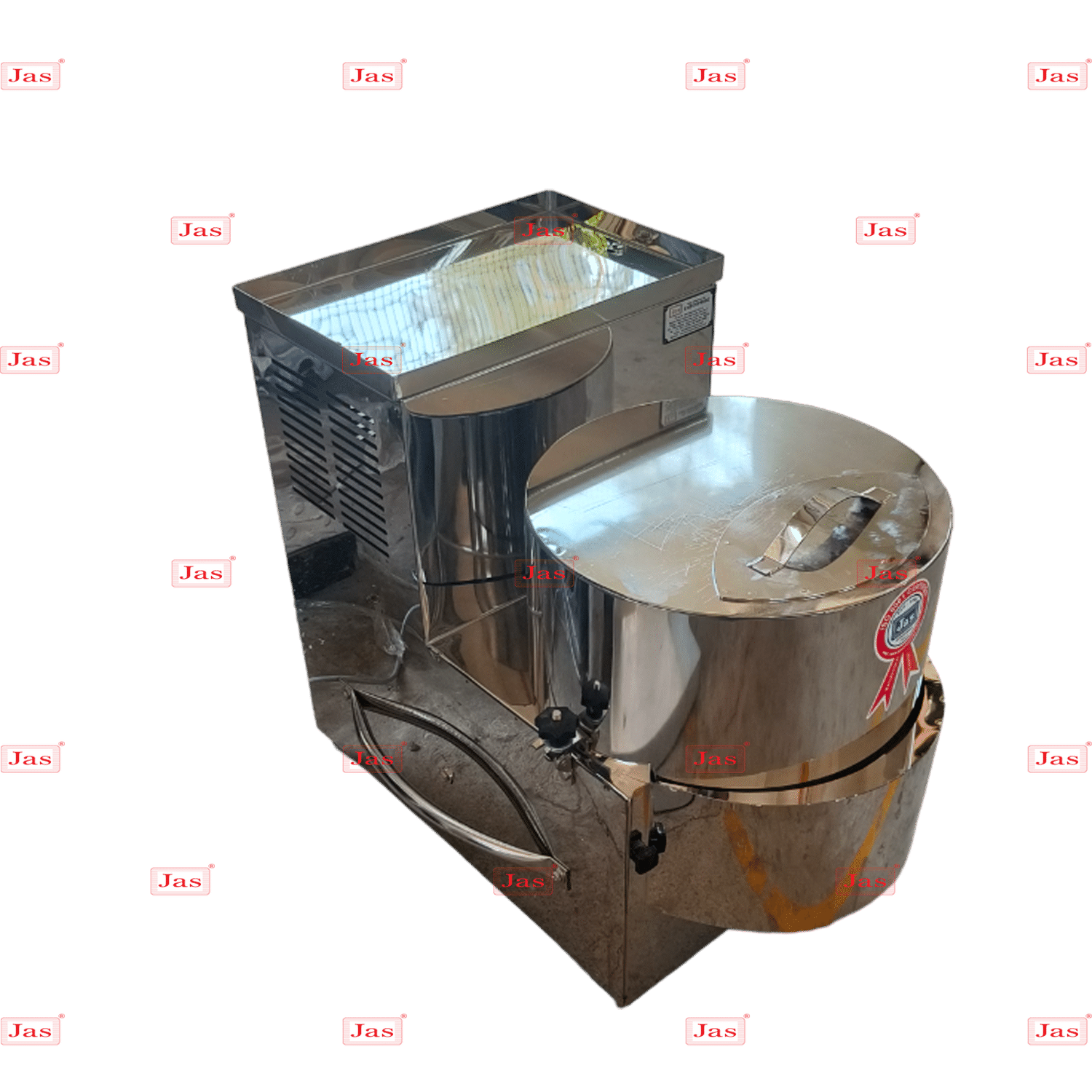

Commercial Slicer

5000 INR/Unit

Product Details:

- Capacity 125-150 Kg/hr

- Automatic Yes

- Voltage 230/440 Volt (v)

- Feature ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- Click to View more

X

Commercial Slicer Price And Quantity

- 1 Unit

- 5000 INR/Unit

Commercial Slicer Product Specifications

- 230/440 Volt (v)

- Yes

- 125-150 Kg/hr

- ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

Commercial Slicer Trade Information

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque Western Union

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- ISO

Product Description

Types of Commercial Slicers:

-

Manual Slicers:

- Operated by a hand crank or lever.

- Offers more control over thickness and slicing speed.

- Requires more physical effort but tends to be less expensive.

-

Automatic Slicers:

- Powered by an electric motor.

- Provides consistent slices with less manual effort.

- Ideal for high-volume operations.

Features to Look For:

-

Blade Size:

- Blades can range from 7 to 14 inches in diameter.

- Larger blades are generally used for slicing larger or thicker products.

-

Thickness Adjustment:

- Look for precise control to adjust the thickness of slices.

- This feature is crucial for ensuring consistency in food preparation.

-

Build Quality:

- Typically made from stainless steel or aluminum for durability and ease of cleaning.

- Some models feature removable parts for thorough sanitation.

-

Safety Features:

- Safety guards and blade covers to protect users from accidental cuts.

- Non-slip feet or suction cups to keep the slicer stable during use.

-

Ease of Cleaning:

- Removable parts and smooth surfaces make cleaning easier and more effective.

Maintenance Tips:

-

Regular Cleaning:

- Clean the slicer after each use to prevent the buildup of food residues.

- Disassemble parts as needed for a thorough cleaning.

-

Blade Sharpening:

- Keep the blade sharp for efficient slicing and to reduce strain on the motor.

- Use a specialized sharpener or have it professionally sharpened.

-

Inspect for Wear and Tear:

- Regularly check for any signs of damage or wear, especially in high-use environments.

-

Lubrication:

- Apply food-safe lubricants to moving parts as recommended by the manufacturer.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email