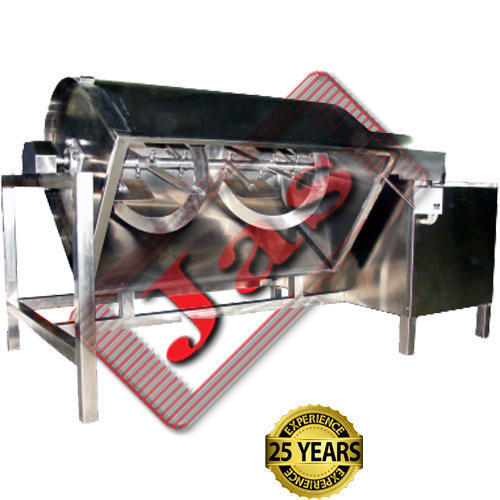

Circular Fryer Machine

300000 INR/Piece

Product Details:

- Material Stainless Steel

- Computerized No

- Automatic Yes

- Power 1500 Watt (w)

- Click to View more

X

Circular Fryer Machine Price And Quantity

- 1 Piece

- 375000.00 - 650000.00 INR/Piece

- 300000 INR/Piece

Circular Fryer Machine Product Specifications

- No

- Stainless Steel

- Yes

- 1500 Watt (w)

Circular Fryer Machine Trade Information

- 1000 Piece Per Month

- 1 Months

- All India

- ISO 9001:2015

Product Description

In these fryers edible oil is heated indirectly in a stainless steel coiled furnace having very high edible oil flow rates passing through it. This ensures very low metal temperatures, thereby avoiding the chances of any deterioration of edible oil and accumulation of particulate in stainless coils are fitted beneath the fry pan. The residual heat from the automatic burner is absorbed by the bottom of fry pan providing double heating system. This heated oil is directly supplied to fry pan and returns back via batch filter. Oil is heated with automatic burner. This fryer with inbuilt heat exchanger system gives efficiency of 92%. The batch fryer quickly and uniform heating of cooking oil with low film temperatures. Low oil volume promotes fast turnover and low fatty free acid level. It's a cost effective system, saves fuel up to 50%. It is a customized system designed as per the requirement. Minimal initial cost compared to thermic fluid based system.Auto shut system for temperature control. No risk of oil contamination by thermic fluid as whole system is edible oil heated. Compared to thermic fluid systems oil heater take very less space due to its vertical design. High quality insulation inside the oil heater for cools outer surfaces and avoids heat loss. High production of namkeen and chips products with reduced labor cost. The stainless steel tubes are self draining tuning design for cleaning. Clean and hygienic factory environment due to external heating system. Ready products can be in single stock due to tilting system.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email