Call us:

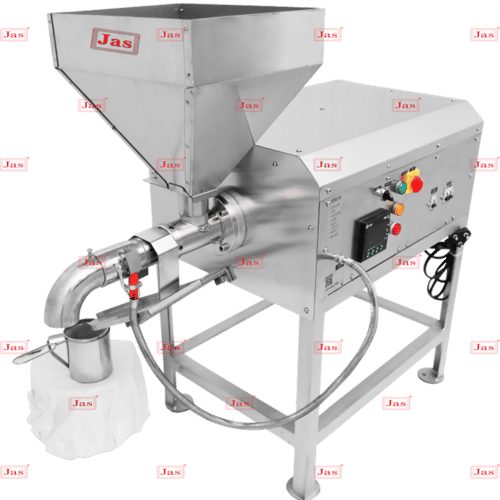

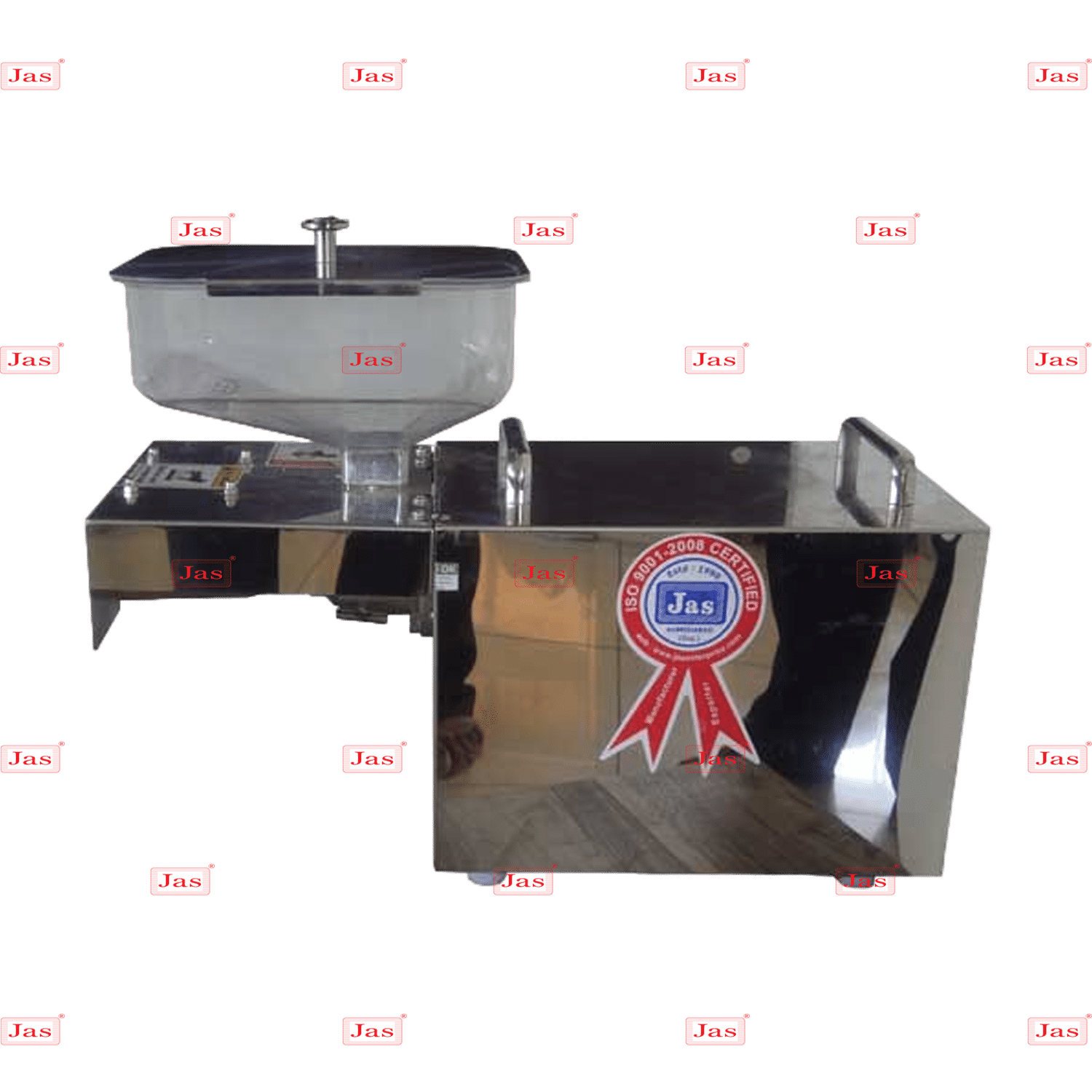

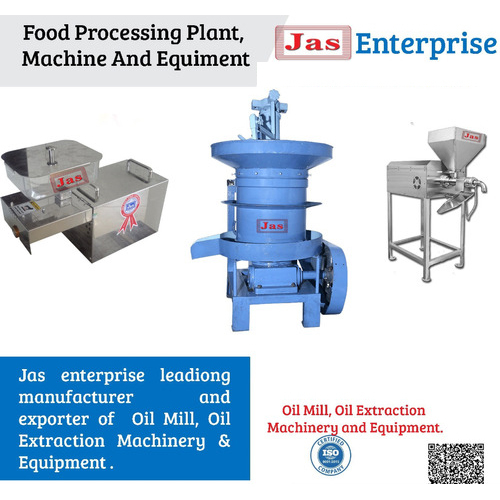

Rotary Oil Extraction Machine

16000 INR/Unit

Product Details:

- Capacity 2-25 Kg/hr

- Automatic Yes

- Voltage 230/440 Volt (v)

- Feature ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- Click to View more

X

Rotary Oil Extraction Machine Price And Quantity

- 16000 INR/Unit

- 16000.00 - 213000.00 INR/Unit

- 1 Unit

Rotary Oil Extraction Machine Product Specifications

- 230/440 Volt (v)

- Yes

- ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- 2-25 Kg/hr

Rotary Oil Extraction Machine Trade Information

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque Western Union

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- ISO

Product Description

How It Works

- Feeding: Raw materials (like soybeans, sunflower seeds, or peanuts) are fed into the machine.

- Crushing: The materials are first crushed or flaked to increase the surface area, making it easier to extract the oil.

- Heating (optional): Some machines have a heating element to preheat the materials, which can help improve oil yield and reduce extraction time.

- Extraction: The core process involves a rotary mechanism”often a screw or a similar component”that presses or squeezes the oil out of the crushed materials. The rotary action helps to apply continuous pressure.

- Filtration: The extracted oil may be filtered to remove solid particles and impurities.

- Collection: The filtered oil is collected, while the remaining solid material (called cake or residue) is discharged.

Types

- Cold Press: Extracts oil without applying heat, preserving more nutrients and flavors.

- Hot Press: Uses heat during extraction, which can increase yield but may affect flavor and nutritional quality.

- Expeller Press: Uses a mechanical screw to press oil from seeds. It's a common type of rotary machine.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email