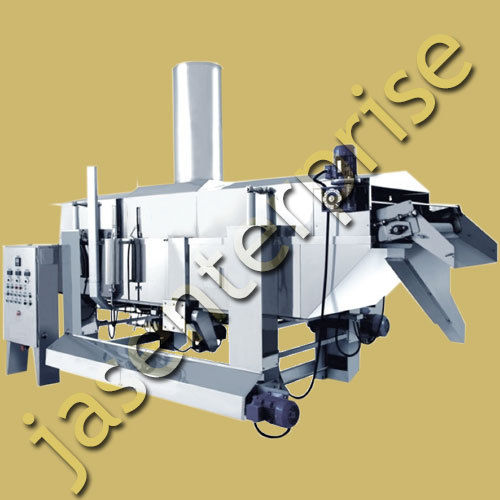

Semi Automatic Chips Making Machine

उत्पाद विवरण:

- क्षमता किलो/घंटा

- ऑटोमेटिक

- वोल्टेज वोल्ट (v)

- फ़ीचर

- अधिक देखने के लिए क्लिक करें

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- किलो/घंटा

- वोल्ट (v)

व्यापार सूचना

- ISO

उत्पाद वर्णन

Key Components and Features

-

Feeding System: This part of the machine handles the raw potatoes or other vegetables. It often includes a hopper where the vegetables are loaded and an automatic feeder that transports them to the cutting section.

-

Cutting Mechanism: The machine usually features a slicer or dicer that cuts the vegetables into thin slices or desired shapes for chips. This part is often adjustable to produce different sizes or thicknesses.

-

Blanching Unit: Some machines have a built-in blanching section that briefly cooks the chips in hot water or steam to remove excess starch and improve texture.

-

Frying System: Semi-automatic machines may come with an integrated fryer or a system to transfer the sliced potatoes to an external fryer. The frying process can be monitored and adjusted manually.

-

Seasoning Application: After frying, chips often need to be seasoned. A semi-automatic machine might have a mechanism for applying seasoning or salt, but operators usually need to adjust and manage this process.

-

Cooling and Packaging: After frying and seasoning, chips need to be cooled before packaging. The machine might include a cooling conveyor and a system for packing the finished chips into bags or containers.

-

Control Panel: A semi-automatic machine will have a control panel where operators can adjust settings such as temperature, cutting thickness, and frying time.

-

Safety Features: To ensure safe operation, these machines are equipped with various safety features, including emergency stops and guards to protect operators from moving parts.

Advantages

- Cost-Effective: Semi-automatic machines are generally more affordable than fully automatic systems, making them suitable for small to medium-sized businesses.

- Flexibility: They offer flexibility in production, allowing for manual adjustments to accommodate different types of chips or recipe changes.

- Efficiency: They improve efficiency compared to purely manual methods, reducing labor costs and production time.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+