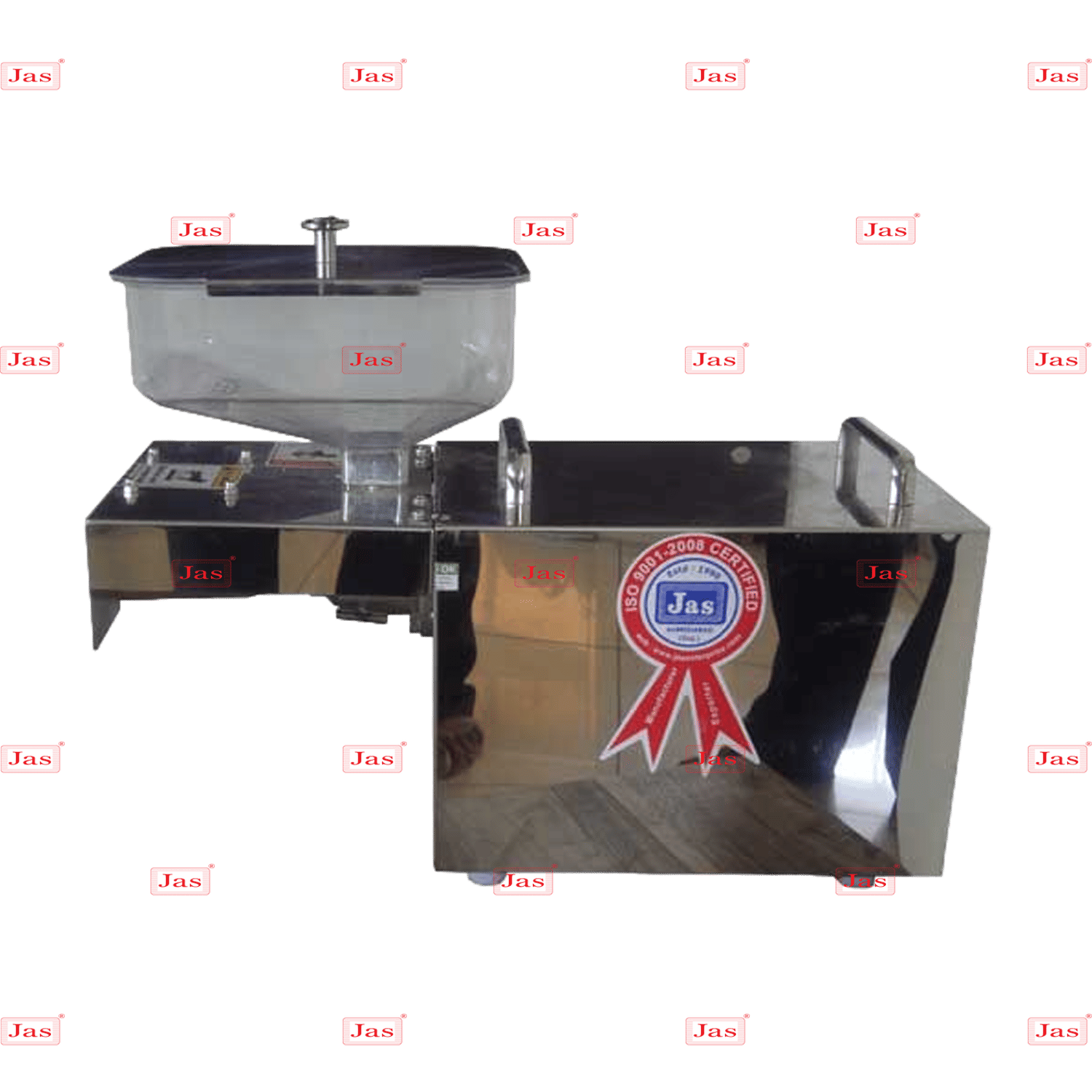

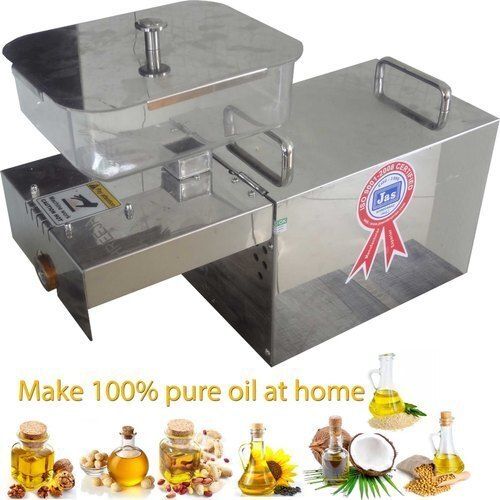

Oil Press Machine

16000 आईएनआर/Unit

उत्पाद विवरण:

- क्षमता किलो/घंटा

- ऑटोमेटिक

- वोल्टेज वोल्ट (v)

- फ़ीचर

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- किलो/घंटा

- वोल्ट (v)

व्यापार सूचना

- ISO

उत्पाद वर्णन

Types of Oil Press Machines

-

Cold Pressing (Expeller Press)

- Process: Seeds or nuts are pressed at low temperatures, which helps retain the nutrients and flavor of the oil. This method is often used for high-quality oils like olive oil, coconut oil, and flaxseed oil.

- Advantages: Retains more nutrients, produces a higher-quality oil.

-

Hot Pressing

- Process: Seeds or nuts are heated before pressing. This can increase oil yield but might reduce the nutritional value and flavor.

- Advantages: Higher oil yield compared to cold pressing.

-

Hydraulic Press

- Process: Uses hydraulic pressure to extract oil. This method is often used for smaller batches and high-quality oils.

- Advantages: Very high oil extraction efficiency, good for specialty oils.

-

Screw Press (Expeller)

- Process: Uses a screw or worm gear to compress the seeds and extract oil. This is commonly used in larger scale operations.

- Advantages: Continuous operation, high extraction efficiency, suitable for large quantities.

Key Components of an Oil Press Machine

- Feeder: Where raw materials are introduced into the machine.

- Press Chamber: The area where the mechanical pressure is applied to extract oil.

- Screw or Hydraulic System: Mechanism for applying pressure.

- Oil Outlet: Where the extracted oil exits the machine.

- Cake Outlet: Where the remaining solid material (cake) exits the machine.

Uses of Oil Press Machines

- Food Industry: For producing cooking oils, salad oils, and specialty oils.

- Cosmetics: For extracting oils used in skincare and beauty products.

- Biofuels: For producing biodiesel from vegetable oils.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email